| –

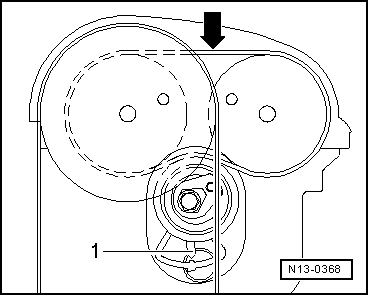

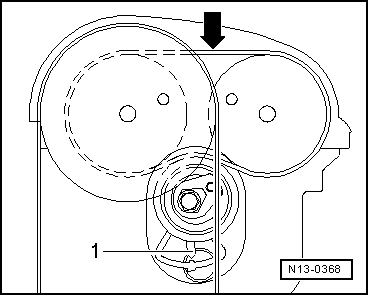

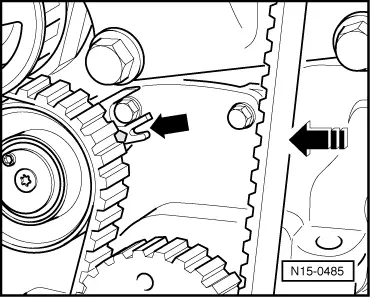

| Note position of tensioning roller indicator -1-. Press toothed belt forcefully with thumb -arrow-. The indicator must move. |

| –

| Release tension on toothed belt. |

| –

| Turn crankshaft two turns in engine direction of rotation. |

| –

| Then check position of indicator. It must have returned to its original position. |

| If tensioning roller does not return to its initial position |

| –

| Replace tensioning roller. |

| If both tensioning rollers are OK |

| –

| Refit lower toothed belt guard. |

| –

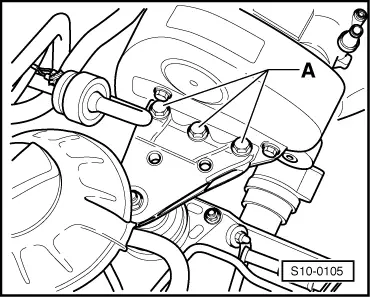

| Refit crankshaft pulley. When doing this, note the following |

| t

| The belt pulley securing bolt and the toothed belt pulley must be renewed. |

| t

| When installing pulley, observe fixing arrangement to toothed belt pulley. |

| t

| Tightening procedure for the new oiled bolt: 90 Nm + 1/4 turn (90°) further. |

| –

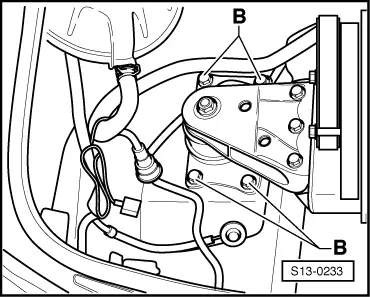

| Fit engine bracket to cylinder head. Torque setting: 50 Nm. |

| –

| Install poly V-belt tensioning element again on vehicles with an air conditioning system. |

| –

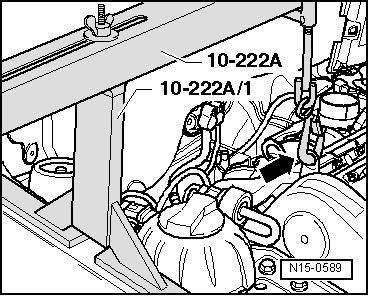

| Install engine mounting. Prescribed torque → Chapter. |

| –

| Install top toothed belt guard. |

Note | When installing poly V-belt, ensure that belt seats correctly in pulley. |

| –

| Install engine splash guard. |

| –

| Bolt on coolant expansion tank. |

|

|

|

Note

Note