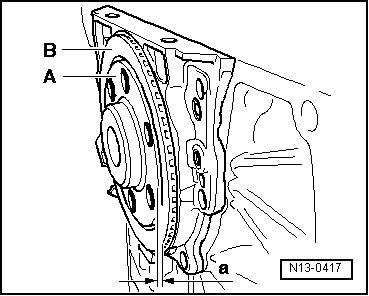

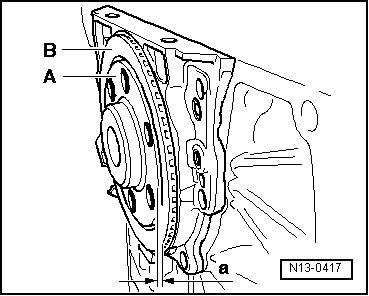

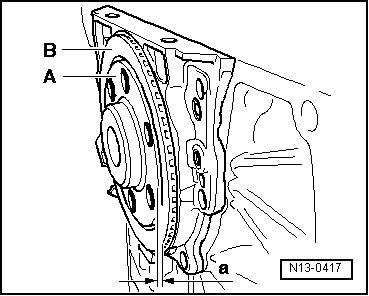

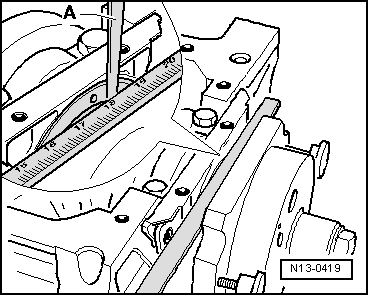

| The sender wheel is in the correct installation position on the crankshaft if a gap -a- = 0.5 mm exists between crankshaft flange -A- and sender wheel -B-. |

Note | t

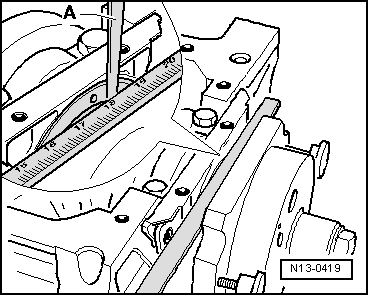

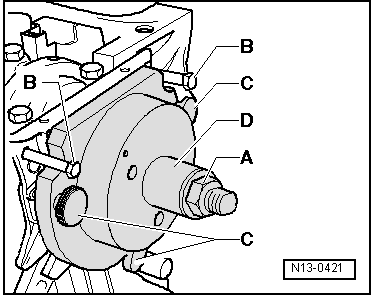

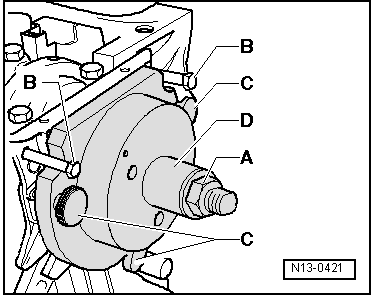

| If the sealing flange has a PTFE sealing ring, completely unbolt the assembly appliance -T10017- and remove the sealing lip support ring. |

| t

| To enable dimension -a- to be shown more clearly the crankshaft flange is illustrated without fitted assembly appliance -T10017-. |

|

|

|

Note

Note

Note

Note