| –

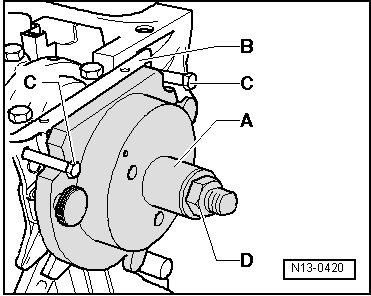

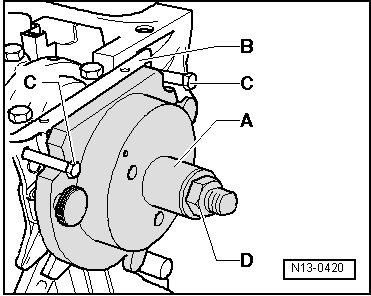

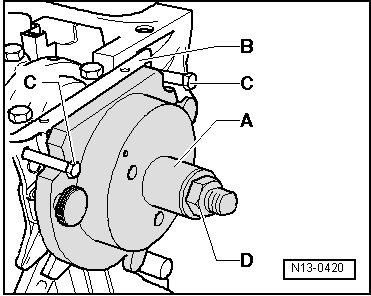

| Slide assembly bell housing -A- to sealing flange -B- by hand. |

| –

| Screw two M6×35 mm bolts -C- into cylinder block to guide sealing flange -B-. |

| –

| Screw hexagon nut -D- along threaded spindle, by hand, until it contacts the assembly bell housing -A-. |

|

|

|