Polo Mk4

| Pistons and rods - disassemble and assemble |

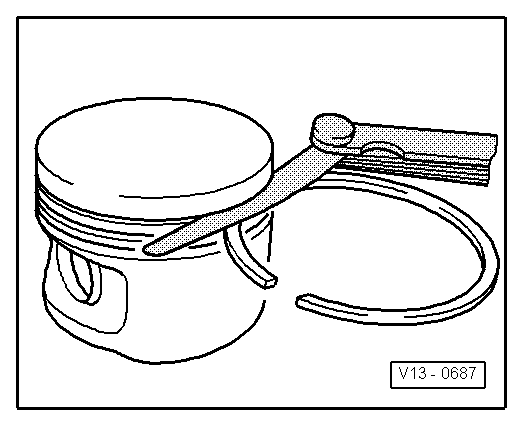

| 1 - | Guide rings |

| q | Displace opening 120° |

| q | Remove and install with ring plier |

| q | Reference “TOP” turned to piston head |

| q | Check intergate openings → Fig. |

| q | Check ring space on piston channel → Fig. |

| 2 - | Piston |

| q | With combustion chamber |

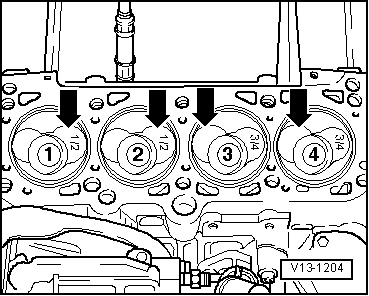

| q | Mark installation position and cylinder correspondence |

| q | Piston/cylinder installation position → Fig. |

| q | -Arrow- on piston head points to belt pulley side |

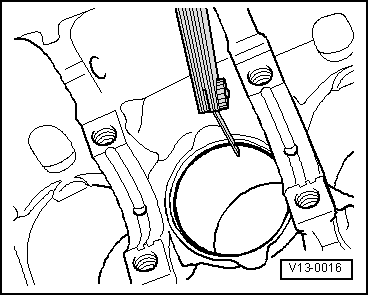

| q | Install with ring tension belt |

| q | If piston is cracked, replace it |

| q | Check piston position on upper part → Chapter. |

| 3 - | Piston pin |

| q | If piston is locked, heat at 60 °C |

| q | Remove and install with Drift -VW 222A- |

| 4 - | Lock |

| 5 - | Rod |

| q | Replace only set |

| q | Mark cylinder position -A- |

| q | Installation position: Markings -B- point to belt pulley side |

| 6 - | Adjusting pin |

| q | Adjusting pin must be firmly positioned on rod |

| 7 - | Cap |

| q | Mind installation position |

| q | Do not change used caps position |

| q | Mind proper seating on retaining protuberances |

| q | Axial space wear limit: 0.37 mm. |

| q | Measure radial space with “Plastigage”: wear limit: 0.08 mm. During radial space measurement, do not move crankshaft |

| 8 - | Engine block |

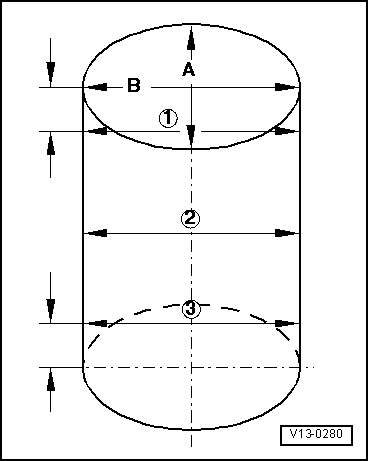

| q | Check cylinder diameter → Fig. |

| q | Piston and cylinder measures → Chapter. |

| 9 - | Rod cover |

| q | Mind installation position |

| 10 - | Oil ejector |

| q | For piston cooling |

| 11 - | 25 Nm |

| q | Install without seal |

| 12 - | Rod screw, 30 Nm + 90 |

| q | Replace |

| q | Oil thread and support surface |

| q | For radial space measurement, use used screw |

| Segment ring measures in mm | new | Wear limit |

| 1. Compression ring | 0.25...0.40 | 1.0 |

| 2. Compression ring | 0.20...0.40 | 1.0 |

| Oil scraper ring | 0.25...0.50 | 1.0 |

|

|

| Segment ring measures in mm | new | Wear limit |

| 1. Compression ring | 0.06...0.09 | 0.25 |

| 2. Compression ring | 0.05...0.08 | 0.25 |

| Oil scraper ring | 0.03...0.06 | 0.15 |

Note

Note

|

|

Note

Note

|

|