Polo Mk4

Note

Note

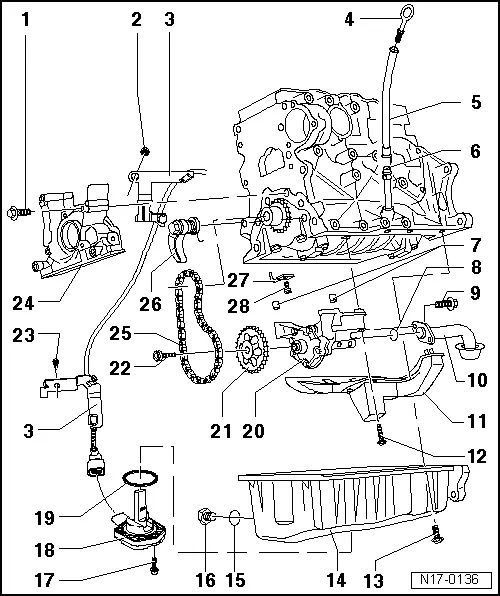

|

| 1 - | 15 Nm |

| 2 - | 25 Nm |

| 3 - | Support |

| q | Level sensor wiring harness-/oil temperature. |

| 4 - | Oil level measuring stick |

| q | Oil level must not be over the max. marking! |

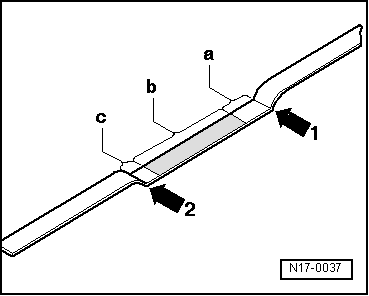

| q | Markings → Fig., → Fig. |

| 5 - | Stick tube |

| q | Remove to suck oil |

| 6 - | Guide tube |

| 7 - | Guide bushing |

| 8 - | Sealing ring |

| q | Replace |

| 9 - | 15 Nm |

| 10 - | Suction tube |

| q | Clean sieve if dirty |

| 11 - | Anti-shake board |

| 12 - | 15 Nm |

| 13 - | 15 Nm |

| 14 - | Oil carter |

| q | Clean sealing surface before assembly |

| q | Assemble with silicone seal -D 176 404 A2- → Chapter. |

| 15 - | Sealing ring |

| q | Replace |

| 16 - | Oil draining plug 30 Nm |

| 17 - | 10 Nm |

| 18 - | Oil level and temperature sensor -G266- |

| q | Black 3-pin linking connector |

| q | Check: → Electric systems folder, fault location with VAS 5051 |

| 19 - | Sealing ring |

| q | Replace |

| 20 - | Oil pump |

| q | With 12 bar over-pressure valve |

| q | Before installation, check if both guide-bushings for oil pump/engine block centralization are in place |

| q | Replace in case fluting is formed on the sliding surfaces and on gears |

| 21 - | Oil pump chain gear |

| 22 - | 25 Nm |

| 23 - | 15 Nm |

| 24 - | Sealing flange |

| q | With sealing ring |

| q | Must seat on guide-pins |

| q | Remove and install → Chapter. |

| q | Assemble with silicone seal -D 176 404 A2- → Chapter. |

| q | Do not lubricate sealing lip of seal |

| q | Before installation, remove oil residues on crankshaft neck with a clean cloth |

| q | Crankshaft sealing ring -pulley side- replace → Chapter and → Chapter. |

| 25 - | Chain |

| 26 - | Chain strainer with tightening rail, 15 Nm |

| q | When installing, pre-tighten spring and hook |

| 27 - | Oil ejector |

| q | For piston refrigeration |

| 28 - | 25 Nm |

| q | Assemble without sealing |

|

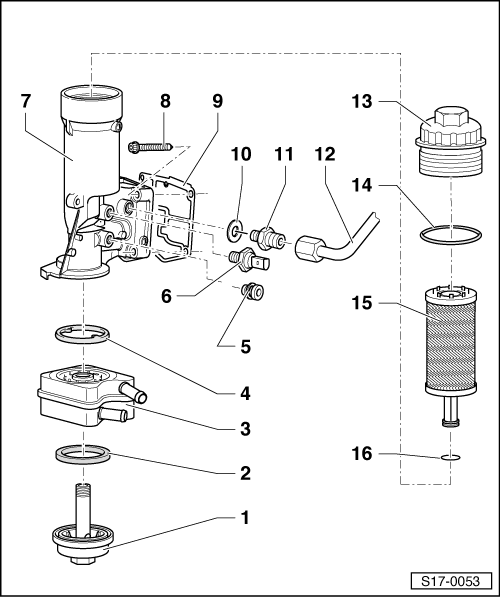

| 1 - | Threaded plug, 25 Nm |

| 2 - | Joint |

| q | Replace |

| 3 - | Oil radiator |

| q | Mind the free space between adjacent components |

| q | Mind the note → Chapter. |

| 4 - | Joint |

| q | Replace |

| 5 - | Threaded plug, 10 Nm |

| q | In case of leakage, cut sealing ring and replace it |

| 6 - | Oil pressure switch -F1-, 20 Nm |

| q | 0.7 bar switch: brown or 0.9 bar switch: gray |

| q | In case of leakage, cut sealing ring and replace it |

| q | Check → Chapter. |

| 7 - | Oil filter support |

| 8 - | 15 Nm + 90 ° |

| q | Replace |

| q | First seat screw on top left and below right, then tighten 4 screws in cross |

| 9 - | Joint |

| q | Replace |

| 10 - | Sealing ring |

| q | Replace |

| 11 - | Connection flange 35 Nm |

| 12 - | Oil supply tube |

| q | To the turbo-compressor |

| 13 - | Draining plug, 25 Nm |

| q | Loosen and tighten with oil filter wrench 3417 |

| 14 - | Sealing ring |

| q | Replace |

| 15 - | Oil filter placement |

| q | Observe installation position: top = top |

| 16 - | Sealing ring |

| q | Replace |