Polo Mk4

| 1 - | 100 Nm |

| q | To remove and install, use the Spanner -3415 -. |

| 2 - | Camshaft gear |

| 3 - | Sealing ring |

| q | Replace → Chapter. |

| 4 - | Key |

| q | Check firm fitting. |

| 5 - | 20 Nm |

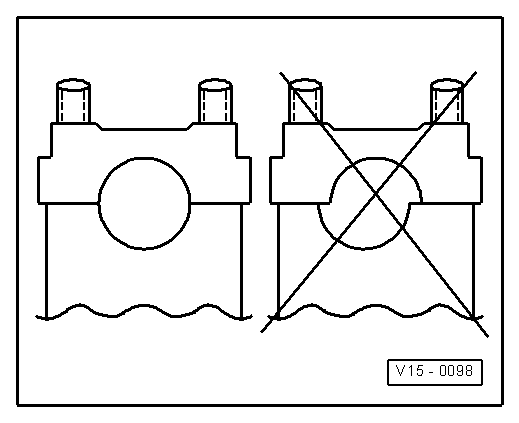

| 6 - | Bearing cover |

| q | Assembly position → Fig. |

| q | Assembly sequence → Chapter. |

| q | Grease the support surface of bearing cover 1 with the Sealing putty -AMV 174 004 01-. |

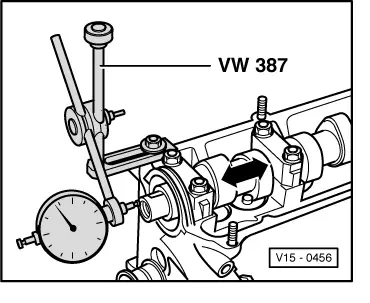

| 7 - | Camshaft |

| q | Check axial clearance → Fig. |

| q | Remove and install → Chapter. |

| q | Measure radial clearance with “Plastigage”: Wear limit: 0.1 mm. |

| q | Runout: max. 0.05 mm. |

| 8 - | Hydraulic tappet |

| q | Do not invert. |

| q | With valve clearance hydraulic offsetting. |

| q | Check → Chapter. |

| q | Place with the contact surface facing down. |

| q | Check camshaft axial clearance before installing → Fig. |

| q | Lubricate contact surfaces. |

| 9 - | Keys |

| 10 - | Upper plate of valve springs |

| 11 - | Valve spring |

| q | Remove and install: Cylinder head removed: with the Compressor device -2037- installed: → Chapter. |

| 12 - | Valve rod oil seal |

| q | Replace → Chapter. |

| 13 - | Valve guide |

| q | Check → Chapter. |

| q | Repair guide with shoulder. |

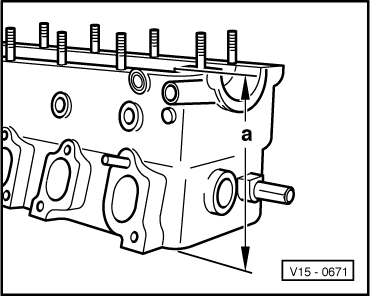

| 14 - | Cylinder head |

| q | Rework the sealing surface → Fig. |

| q | Grind valve seats → Chapter. |

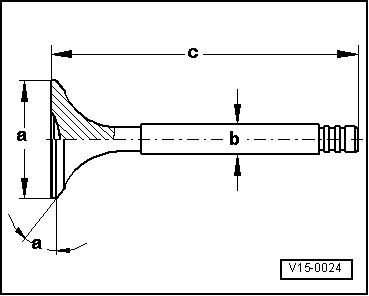

| 15 - | Valves |

| q | Do not grind; only seating is permitted. |

| q | Valve measures → Fig. |

Note

Note

|

|

|

|

|

|

| Identification between cam pairs, intake and exhaust valve of cylinder 1 | |

| Cylinder 1 (BBX engine) | 050 P |

| Cylinder 1 (CFEA engine) | 06A M |

Note

Note

|

|

| Measure | Intake valve | Exhaust valve | |

| Ø a | mm | 39,5 ± 0,15 | 32,9 ± 0,15 |

| Ø b | mm | 6,98 ± 0,007 | 6,96 ± 0,007 |

| c | mm | 91,85 | 91,15 |

| α | ∠° | 45 | 45 |

|

| Intake valve | Exhaust valve | ||

| Then opens | TDC | 6,2° | -------- |

| Then closes | BDC | 42,45° | -------- |

| Opens before | BDC | --------- | 35,8° |

| Then closes | TDC | --------- | 0,45° |