Polo Mk4

Note

Note

|

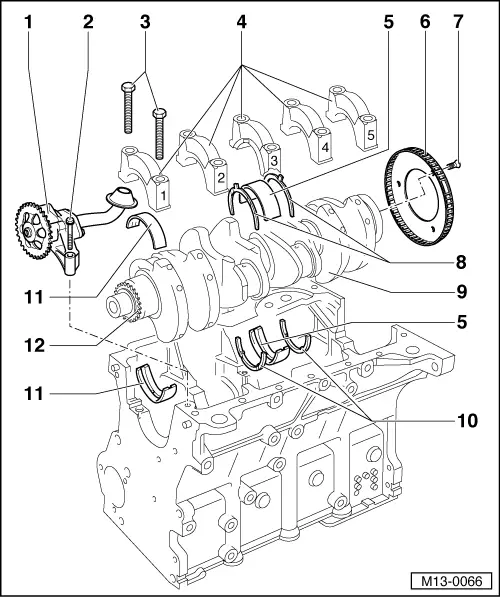

| 1 - | Oil pump |

| q | With 12-bar overpressure valve. |

| q | Before installing, check that both guides for oil pump/crankcase centring are in their positions. |

| q | Remove and install → Chapter. |

| 2 - | 15 Nm |

| 3 - | Gear |

| q | To activate the oil pump. |

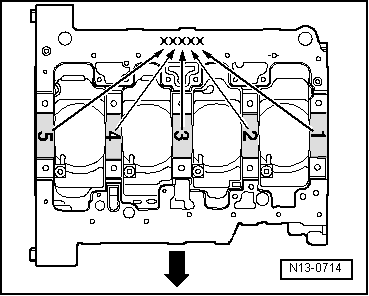

| 4 - | Bearing shells 1, 2, 3, 4 and 5 |

| q | Classification for spare part orders → Fig.. |

| q | For bearing cap without lubrication groove. |

| q | For crankcase with oil groove. |

| q | Do not invert bearing shells already used (identify). |

| 5 - | 65 Nm 90° |

| q | Replace after each removal. |

| q | Tighten to 65 Nm only to measure the radial clearance of the crankshaft. |

| 6 - | Bearing cover |

| q | Bearing cap 1: pulley side. |

| q | Cover of bearing 3 with groove for adjusting rings. |

| q | The shoulders for placing the bearing shells, crankcase/bearing cap must be overlapped. |

| 7 - | Bearing shell 3 |

| q | → Item. |

| q | Do not invert bearing shells already used (identify). |

| 8 - | Speed transmitter |

| q | Replace. |

| q | To Engine speed sensor - G28-. |

| q | The installation is only possible in one position - displaced holes. |

| 9 - | 10 Nm 90° |

| q | Replace after each removal. |

| 10 - | Crankshaft |

| q | Axial clearance (new): 0.07...0.23 mm, Wear limit: 0.30 mm. |

| q | Measure radial clearance with “Plastigage” (new): 0.01...00.04 mm, Wear limit: 0.15 mm. |

| q | Do not rotate the crankshaft when measuring radial gap. |

| q | Crankshaft measures → Chapter. |

| 11 - | Adjustment ring |

| q | For the engine block, bearing 3. |

| q | The writing points to the bearing. |

WARNING

WARNING