| t

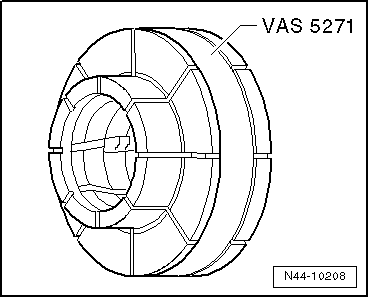

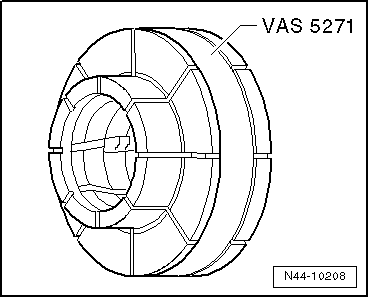

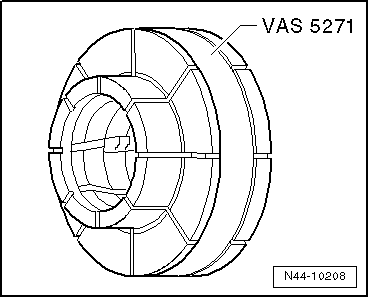

| For attaching the wheel, use, for example, the Centering

system for wheel balancing machines -VAS 5271-. |

| t

| This way, it is assured a central positioning of the wheel

at 100% and a very good attachment |

| t

| It is not possible to position the wheel at 100% to the balancing

machine with conical fixtures. |

| t

| A deviation of 0.1 mm outer of the center causes a misbalance

at the wheel/tyre of 10 grams. |

| Evolution of wheel balancing operation. |

| –

| Turn the wheel at the balancing machine. |

| –

| Check the course of the distinctive curves on the side walls

of the tyre next to the rim flap. |

| –

| Check the design of the tyre tread while the wheel is rolling. |

Note | If there is one-sided wear, due to sudden braking or strong

wear due to abrasion, it is not possible to reach the drive stability

through the wheel balancing. In these cases, the tyre must be replaced. |

| –

| Check the concentricity of the wheel. If the wheel rolls

eccentrically, despite of inexistence of deformation, the cause can

be a radial deviation or an axial deviation. |

| –

| Inspect the wheel for existence of radial and axial deviations → Chapter. |

| –

| If the axial and radial deviation remain within the tolerance

values allowed, perform the balancing of the rim and of the tyre. |

Note | t

| Do not use more than 60 grams of weight for each wheel. |

| t

| If the use of more weight is required, it is possible, occasionally,

to obtain better drive stability through the modification of the positioning

of the tyre in relation to the rim in 1/4 of turn sequentially, until

getting the best result. Correction of deviations in the wheel balancing

through the positioning in relation to the rim. → Chapter |

| t

| The indicator on the balancing machine shall show 0 gram. |

| t

| As an alternative to the deviation in the dynamic balancing

of the wheel, the Wheel balancer -VAS 6202-can be used. |

| –

| Screw the wheel to the vehicle. |

| –

| First, screw the lowest stud of the wheel, not tightening

it much, with approximately 30 Nm. |

| –

| Now, tighten the remaining screws for the wheel similarly

with approximately 30 Nm and on a crisscross pattern. This way, it

is possible the centering of the wheel to the corresponding hub. |

| –

| Put the vehicle on the wheels. |

| –

| Now, tighten the studs of the wheel on a crisscross pattern

with a torque wrench with the tightening torque specified for the

vehicle in question. |

| –

| After balancing the wheel, perform a test drive. |

| If during the test drive the continuation of the drive instability

is perceptible, it may happen due to tolerances existing in the centering

of the wheel. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note