| –

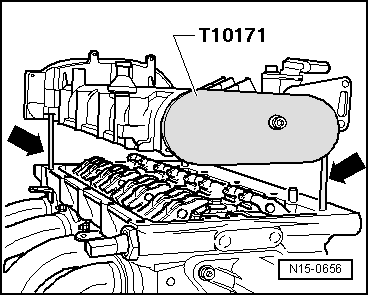

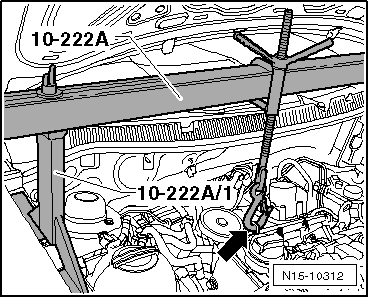

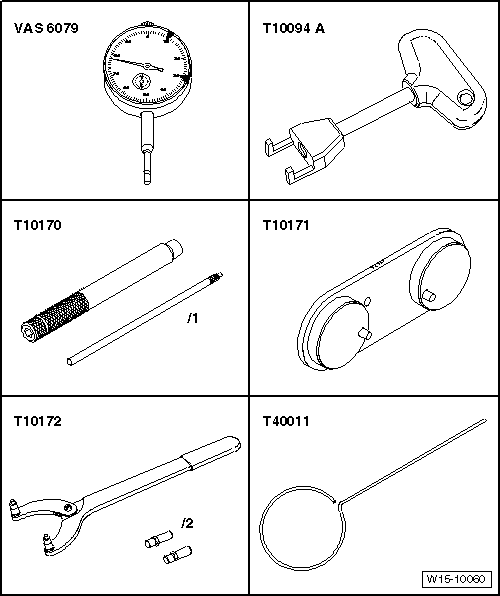

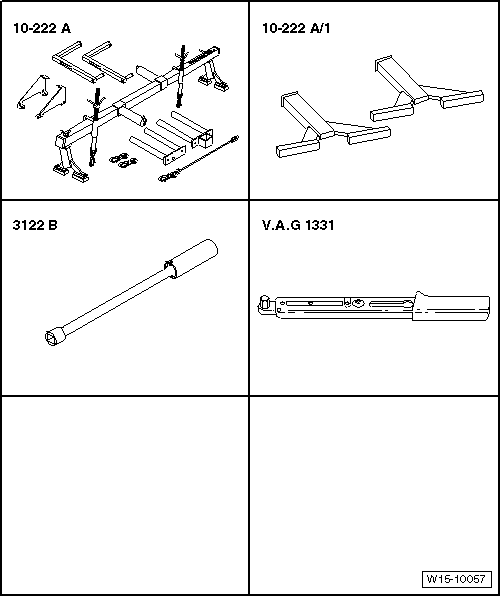

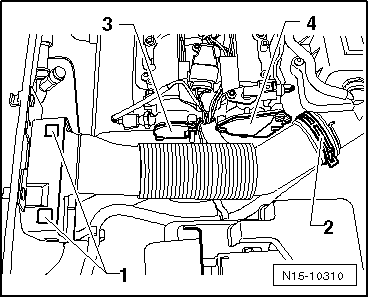

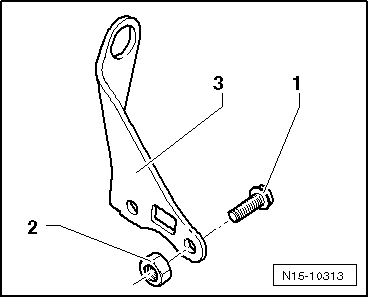

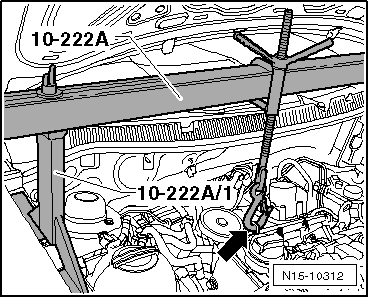

| Install support device -10 - 222 A- with adapter -10 - 222 A /1- as shown and hook into lifting eye -arrow-. |

| –

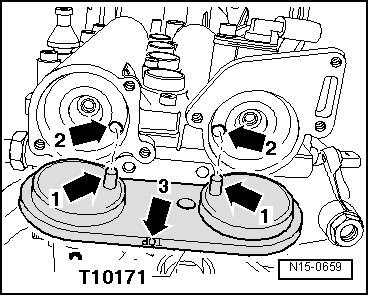

| Turn crankshaft to TDC no. 1 cylinder. Then turn crankshaft back 45° against engine direction and remove camshaft timing sprockets with timing chain → Chapter |

| –

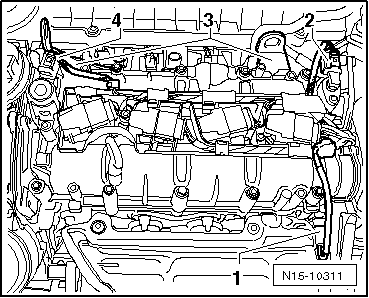

| Remove ignition coils. Use puller -T10094 A- for this purpose → Chapter. |

| –

| Remove cable guide with wiring harness from camshaft housing. |

| –

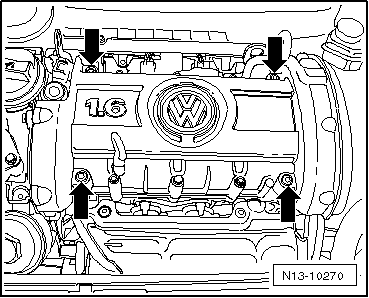

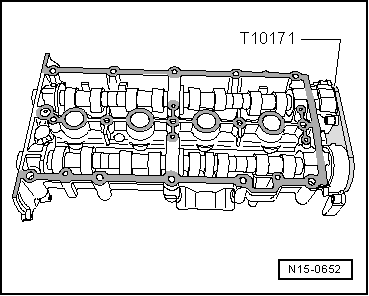

| Loosen camshaft housing bolts from outside to inside, alternately and diagonally and remove. |

| –

| Carefully lift camshaft housing off. |

| l

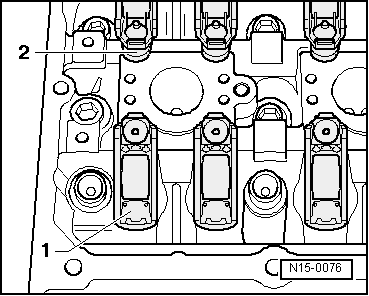

| The pistons must not be positioned at TDC. |

| –

| Remove sealant residue on camshaft housing and cylinder head with a rotating brush, e.g. a hand drill with a plastic brush (wear eye protection). |

| –

| Prevent dirt and residual sealant from entering cylinder head. |

| –

| Clean sealing surfaces carefully. They must be free of oil and grease. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note