Polo Mk5

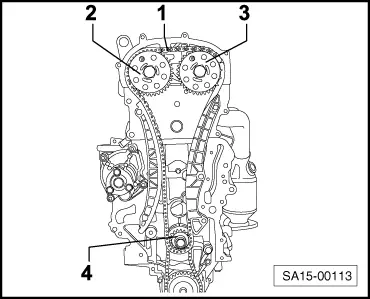

| Removing and installing timing chain and chain drive for oil pump |

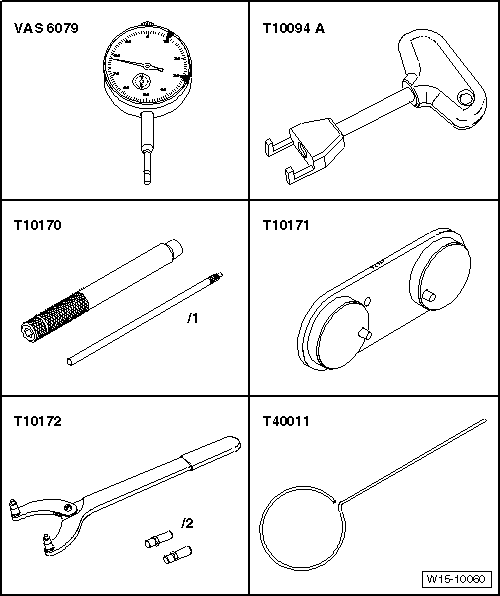

| Special tools and workshop equipment required |

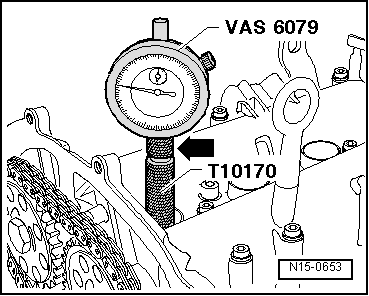

| t | Dial gauge -VAS 6079- |

| t | Puller -T10094 A- |

| t | Dial gauge adapter -T10170- |

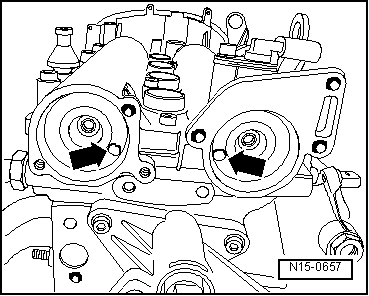

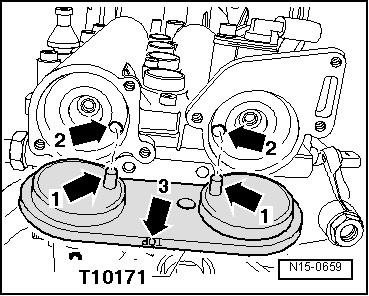

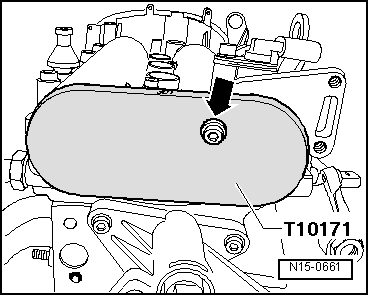

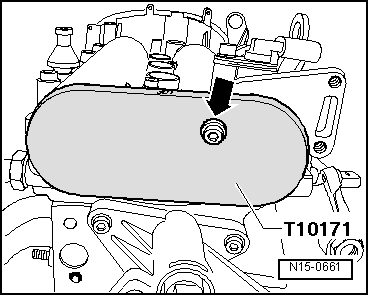

| t | Camshaft clamp -T10171- |

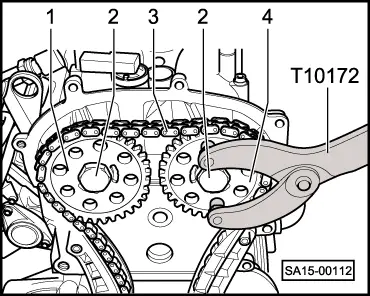

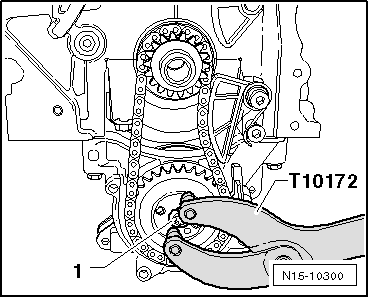

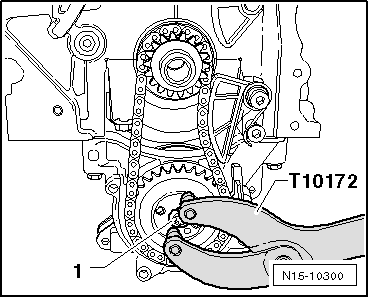

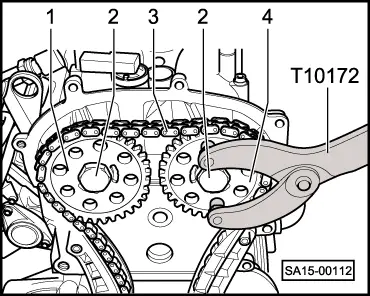

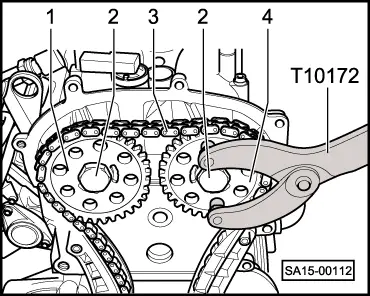

| t | Counterhold tool -T10172- |

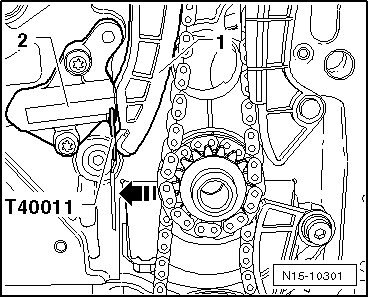

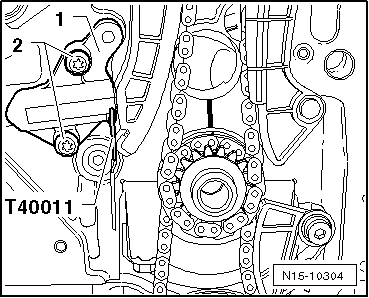

| t | Locking pin -T40011- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Caution

Caution