| Notes on repairs to airbag and belt tensioner wiring |

| In addition to the general notes on repairs to wiring harnesses, the following instructions must be observed on how to repair wiring in airbag and belt tensioner systems: |

WARNING | t

| Airbag and seat belt tensioner can fail. |

| t

| Faulty repairs to the airbag and seat belt tensioning system can cause malfunctions in the passenger protection system. |

| t

| For repairs to airbag and belt tensioner wiring harnesses, only contacts, connectors and wiring designed specifically for this purpose may be used → Electronic parts catalogue (ETKA). |

|

Note | t

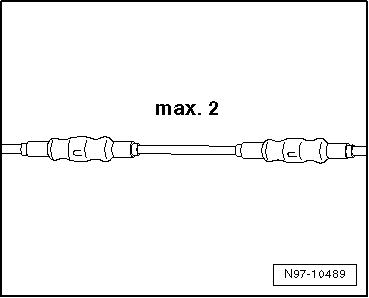

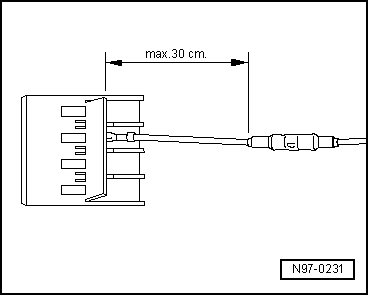

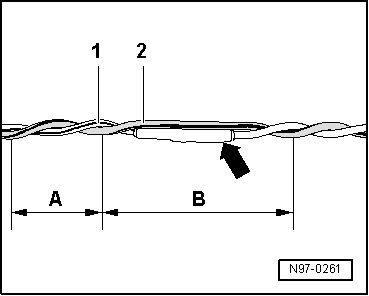

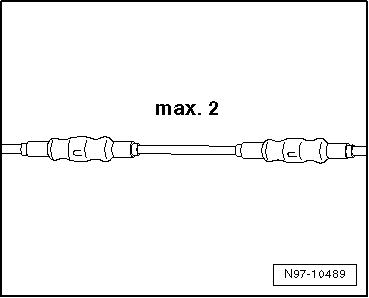

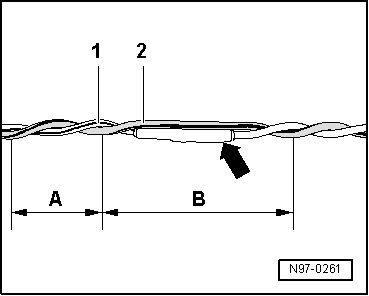

| Wires from airbag and belt tensioner wiring harness may only be repaired using wiring harness repair set -VAS 1978 B- and previous versions. |

| t

| Observe the general notes on repairs to the vehicle electrical system → Chapter. |

|

|

|

Note

Note

Note

Note