| –

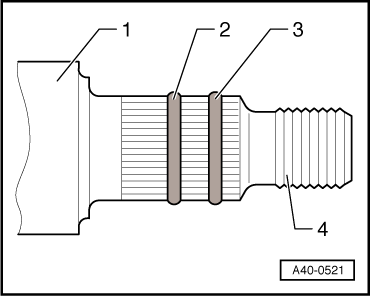

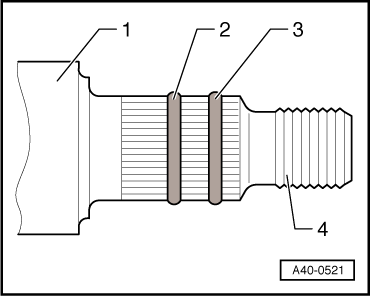

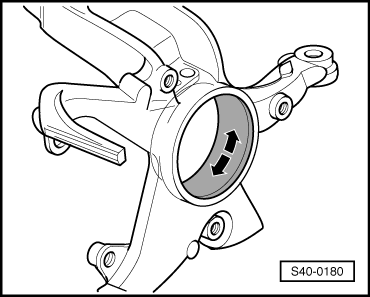

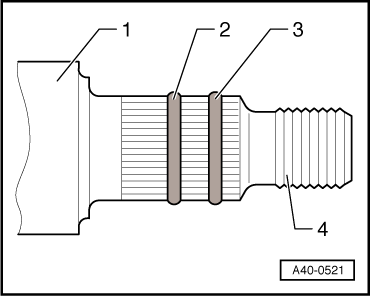

| Apply two beads of locking fluid -D 185 400 A2- on splines as illustrated. Bead diameter approx. 2 mm. |

| 2 - | Bead approximately in centre of splines |

| 3 - | Bead near beginning of splines |

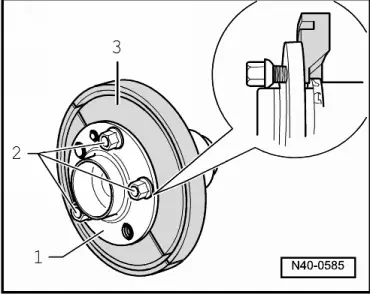

| 4 - | Do not grease thread on outer joint (stub axle). |

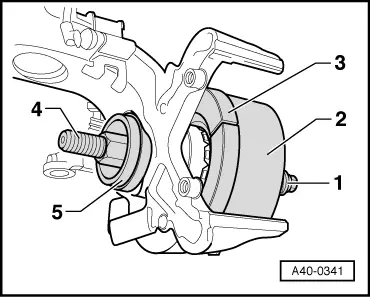

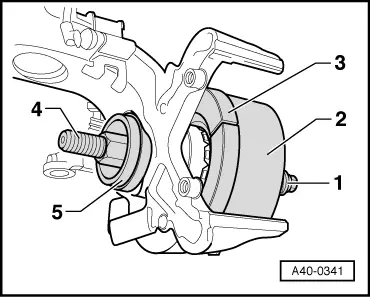

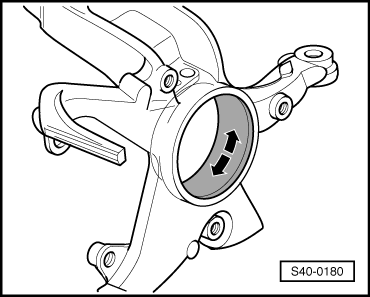

| Vehicles with fabricated wishbone and bolt-on swivel joint |

| –

| When securing swivel joint to wishbone on vehicles with fabricated wishbone, keep to previously marked position of bolts, or original bolt impressions. Use new bolts and a new locking plate with nuts. |

| Observe correct installation sequence of bolts → Item. |

| After installation, check position of steering wheel by test-driving vehicle. |

| Wheel alignment must be checked and adjusted if steering wheel is not in central position when driving straight-ahead. |

| –

| Check and adjust wheel alignment → Chapter. |

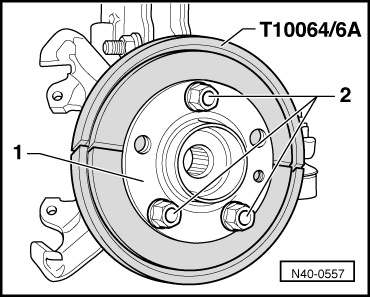

| All vehicles (continued): |

| –

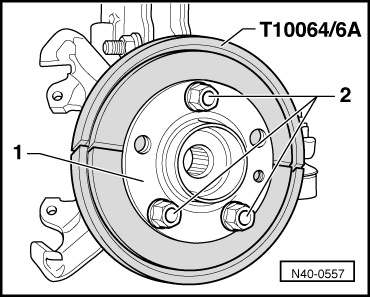

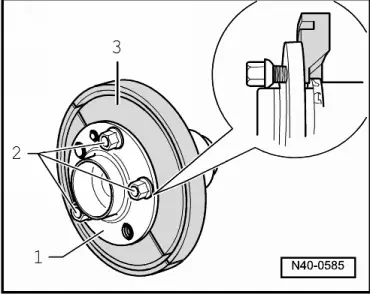

| Always replace hexagon socket nut (pressed-steel version) with a 12-point nut. |

|

|

|

Note!

Note!

Note!

Note!