A3 Mk1

| Adjusting differential |

| Special tools and workshop equipment required |

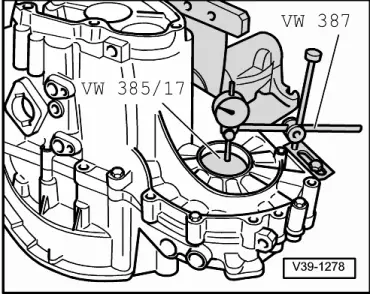

| t | Universal dial gauge bracket -VW 387- |

| t | End measuring plate -VW 385/17- |

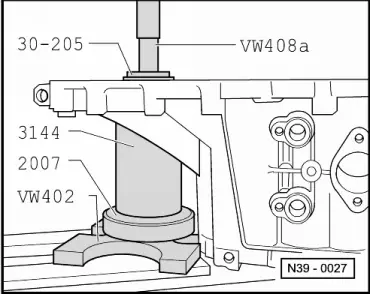

| t | Thrust plate -30-205- |

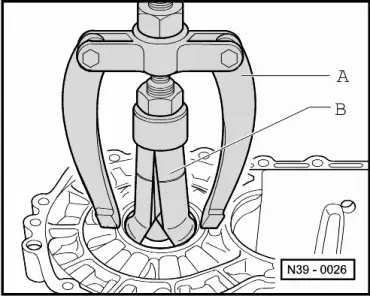

| t | Press tool -VW 407- |

| t | Dial gauge |

Note

Note

|

|

|

|

|

|

| Example: | |

| Dial gauge reading (example) | 0.70 mm |

| Preload (constant value) | + 0.40 mm |

| Thickness of shim | = 1.10 mm |

|

| Available shims - Thickness of shims in mm 1)2)3) | ||||||||

| 0.65 | 0.90 | 1.20 | ||||||

| 0.70 | 0.95 | 1.15 | ||||||

| 0.75 | 1.00 | 1.25 | ||||||

| 0.80 | 1.05 | |||||||

| 0.85 | 1.10 | |||||||

| ||||||||

|

|