A3 Mk1

Note

Note

|

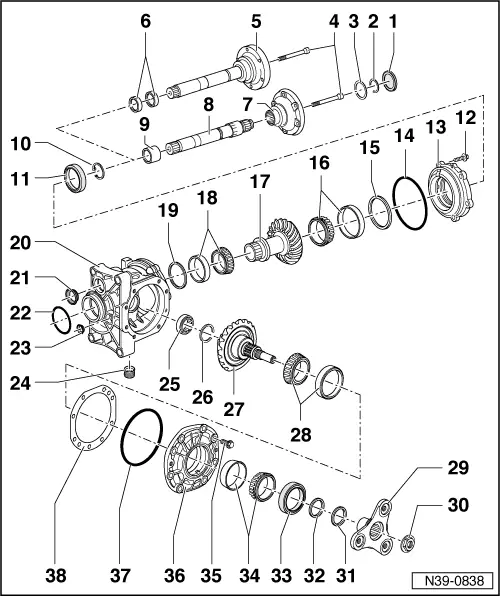

| 1 - | Cap |

| q | Destroyed during removal |

| q | Renew |

| 2 - | Circlip |

| q | Renew |

| 3 - | Dished spring |

| q | Taper faces circlip |

| 4 - | Countersunk bolt, 25 Nm |

| 5 - | Flange shaft |

| 6 - | Needle bearing (polygon bearing) |

| q | 2 x |

| q | Only for flange shaft → Item |

| q | Renewing → Chapter |

| 7 - | Drive flange |

| q | Pulling out → Anchor with output shaft → Item |

| q | Pressing off → Anchor |

| q | Pressing on → Anchor |

| 8 - | Output shaft |

| q | Pull out of bevel box housing → Anchor with drive flange → Item |

| 9 - | Needle bearing (polygon bearing) |

| q | Only for output shaft |

| q | Renewing → Chapter |

| 10 - | Circlip |

| q | Renew |

| 11 - | Oil seal |

| q | Renewing → Chapter |

| 12 - | Bolt, 25 Nm |

| 13 - | Cover |

| q | Removing → Anchor |

| q | Keep straight when installing, tighten securing bolts diagonally and in stages |

| 14 - | O-ring |

| q | Renew |

| q | Must be seated in circumferential groove |

| 15 - | Shim “S1” |

| q | Note thickness |

| q | Table of adjustments → Anchor |

| 16 - | Large tapered roller bearing for bevel gear |

| q | Pulling off inner race → Anchor |

| q | Pressing on inner race → Anchor |

| q | Pressing out outer race → Anchor |

| q | Pressing in outer race → Anchor |

| 17 - | Bevel gear with input shaft |

| q | Is paired with shaft bevel gear → Item |

| q | Cannot be pressed off input shaft |

| q | Adjusting → Chapter |

| 18 - | Small tapered roller bearing for bevel gear |

| q | Pressing off inner race → Anchor |

| q | Pressing on inner race → Anchor |

| q | Pressing out outer race → Anchor |

| q | Pressing in outer race → Anchor |

| 19 - | Shim “S2” |

| q | Note thickness |

| q | Table of adjustments → Anchor |

| 20 - | Final drive housing |

| 21 - | Oil seal |

| q | Renew |

| q | Insert stepped side into final drive housing |

| 22 - | O-ring |

| q | Renew |

| 23 - | Oil seal |

| q | Renew |

| q | Insert stepped side into final drive housing |

| 24 - | Oil drain plug, 25 Nm |

| q | With magnet |

| 25 - | Roller bearing |

| q | Pulling out → Anchor |

| q | Pressing in → Anchor |

| 26 - | Circlip |

| q | Renew |

| q | Removing → Anchor |

| 27 - | Shaft bevel gear |

| q | Is paired with bevel gear |

| q | Clean thread |

| q | Adjusting → Chapter |

| 28 - | Large tapered roller bearing for shaft bevel gear |

| q | Pulling off inner race → Anchor |

| q | Pressing on inner race → Anchor |

| q | Pulling out outer race → Anchor |

| q | Pressing in outer race → Anchor |

| 29 - | Output flange |

| 30 - | Hexagon nut, 350 Nm |

| q | Slackening → Anchor |

| q | Renew |

| q | Lubricate with gear oil before installing |

| q | Tightening sequence → Anchor |

| 31 - | Shim “S4” |

| q | Note thickness |

| q | Table of adjustments → Anchor |

| q | Fit onto spacer ring → Item before installing oil seal → Item and small tapered roller bearing inner race → Item |

| 32 - | Spacer ring |

| q | Installation position: chamfer faces shaft bevel gear → Item |

| q | Fit onto shaft bevel gear → Item before installing oil seal → Item, shim “S4” and small tapered roller bearing inner race → Item |

| 33 - | Oil seal |

| q | Renew only with bevel box removed → Chapter |

| q | Pinion housing → Item does not have to be detached |

| 34 - | Small tapered roller bearing for shaft bevel gear |

| q | Pressing out outer race → Anchor |

| q | Pressing in outer race → Anchor |

| q | Insert inner race in outer race |

| 35 - | Bolt, 25 Nm |

| 36 - | Pinion housing |

| q | Removing → Anchor |

| q | Installing → Anchor |

| q | Keep straight when installing, tighten securing bolts diagonally and in stages |

| 37 - | O-ring |

| q | Renew |

| q | Must rest in circumferential groove |

| 38 - | Shim “S3” |

| q | Note thickness |

| q | Table of adjustments → Anchor |