A3 Mk1

| Dismantling and assembling bevel box |

| Special tools and workshop equipment required |

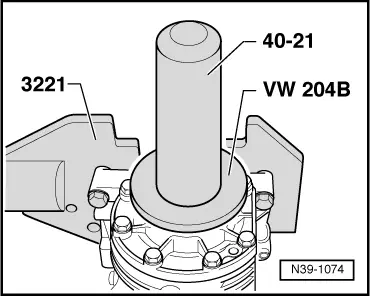

| t | Fitting tool -VW 204 B- |

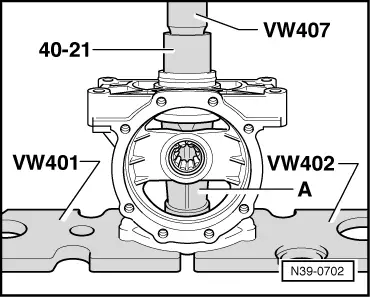

| t | Press tool -40-21- |

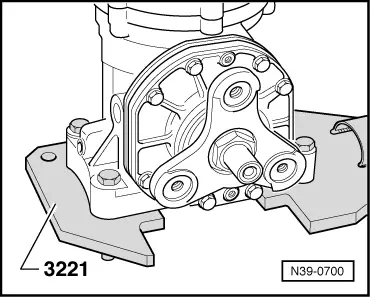

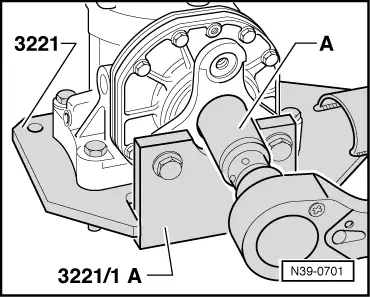

| t | Gearbox support -3221- |

| t | Support plate -3221/1 A - |

| t | Torque wrench -V.A.G 1601- |

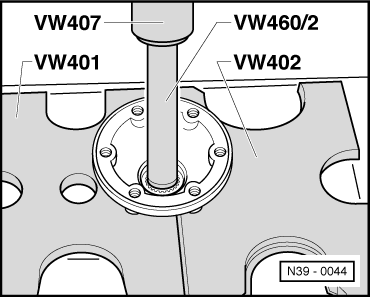

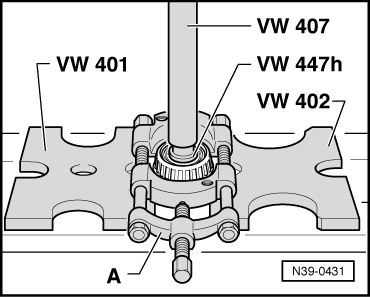

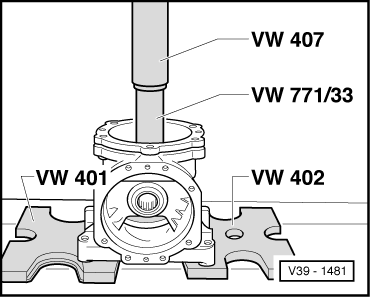

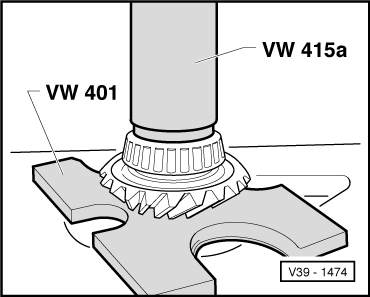

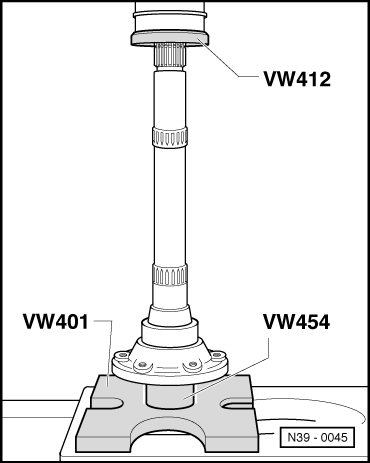

| t | Thrust plate -VW 401- |

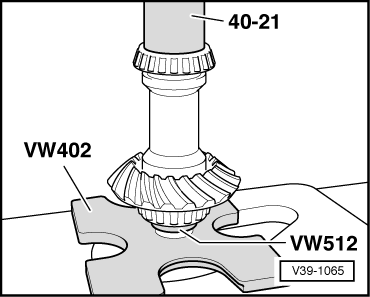

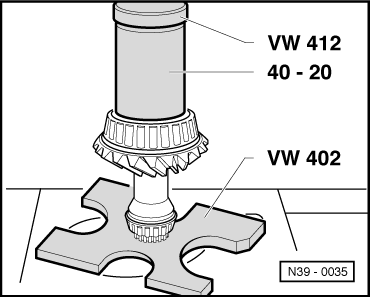

| t | Thrust plate -VW 402- |

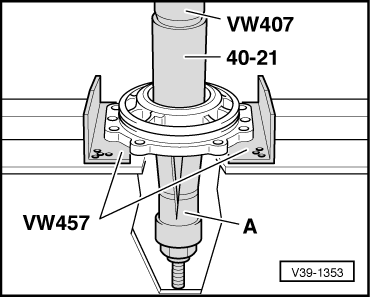

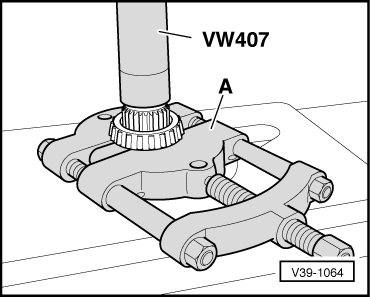

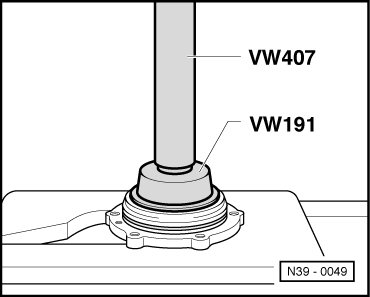

| t | Press tool -VW 407- |

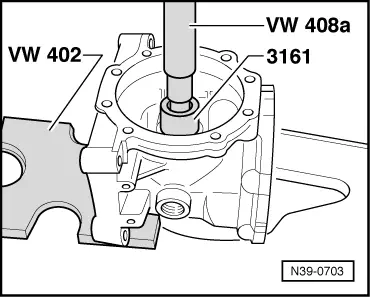

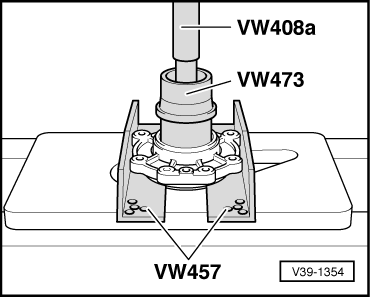

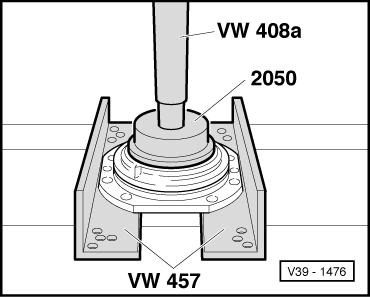

| t | Press tool -VW 408 A- |

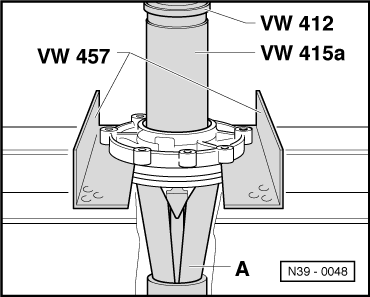

| t | Tube -VW 415 A- |

| t | Torque wrench -V.A.G 1331- |

| t | Support rails -VW 457- |

| t | Press tool -VW 412- |

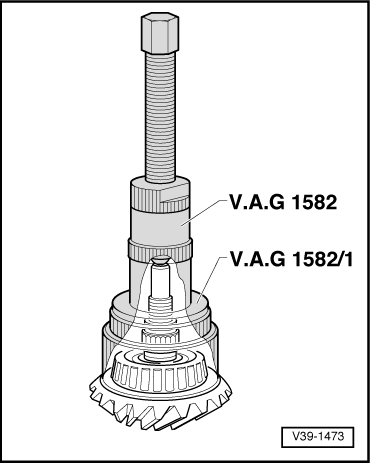

| t | Puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/1- |

| t | Press tool -VW 473- |

| t | Thrust plate -VW 447 H- |

| t | Fitting tool -VW 191- |

| t | Thrust piece -2050- |

| t | Tube -VW 460/2- |

| t | Press tool -VW 454- |

| t | -1-Internal puller -Kukko 21/3-, -Kukko 21/7-, -Kukko 21/8- |

| t | -3-Splitter -Kukko 17/2- |

| t | -4-Counter-support -Kukko 22/1-, -Kukko 22/2- |

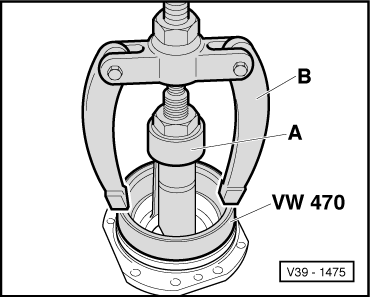

| t | Thrust pieces for pinion shaft bearing -VW 470- |

| t | Thrust pad -VW 512- |

| t | Tube -VW 771/33- |

| t | Drift sleeve -40-20- |

| t | Extension -3161- |

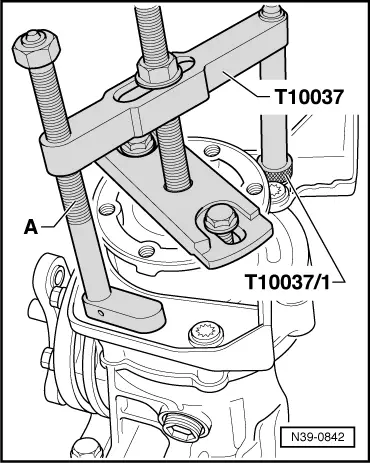

| t | Puller -T10037- |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|