A3 Mk1

| Dismantling and assembling selector forks |

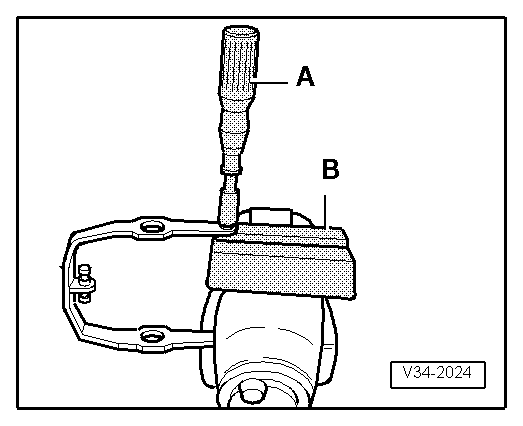

| Special tools and workshop equipment required |

| t | Thrust plate -VW 402- |

| t | Thrust piece -3290/1- from assembly tool -3290- |

| t | Press tool -VW 431- |

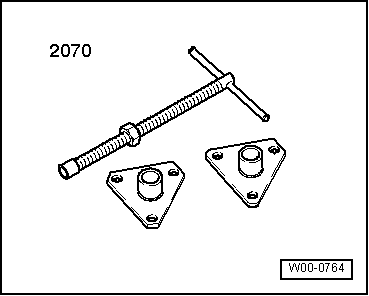

| t | Assembly tool -3301- |

| t | Spacer sleeve -VW 472/2- |

| t | Drift -10-206- |

|

|

|

|

|

|

|

|

| Selector forks - exploded view of components |

Note

Note| The selector fork cluster → Item does not have to be dismantled in order to remove and install detent segments, lock washers and angular contact ball bearings. |

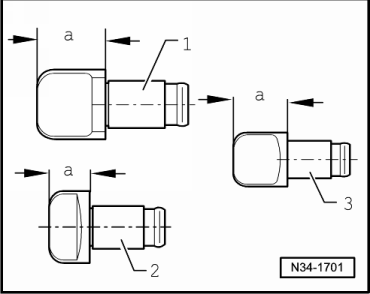

| 1 - | 5th gear detent segment |

| q | Identification → Fig. |

| q | Must rotate freely after lock washer is installed |

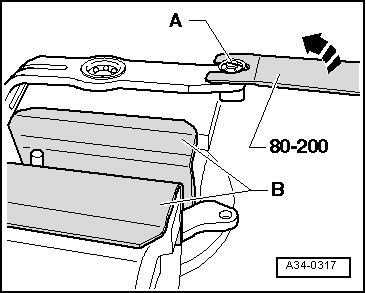

| 2 - | Lock washer |

| q | Renew |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 3 - | 5th gear selector fork |

| q | Adjusting → Anchor |

| 4 - | Bolt, 25 Nm |

| 5 - | 5th gear selector jaw |

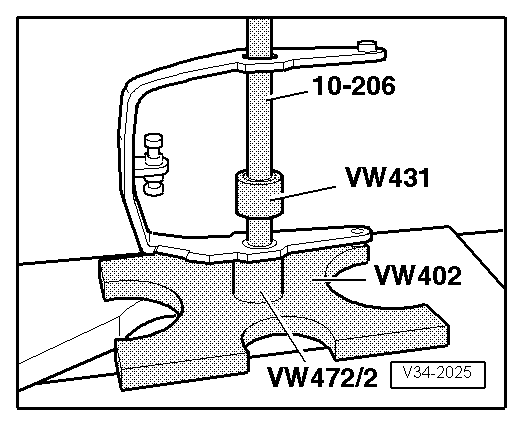

| 6 - | Angular contact ball bearing |

| q | 4 x |

| q | Removing → Fig. |

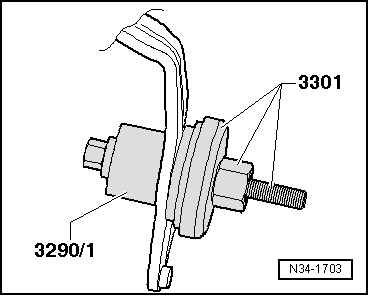

| q | Pressing inner race into outer race → Fig. |

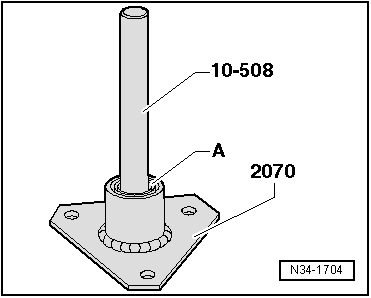

| q | Installing → Fig. |

| 7 - | Selector fork cluster with selector plates |

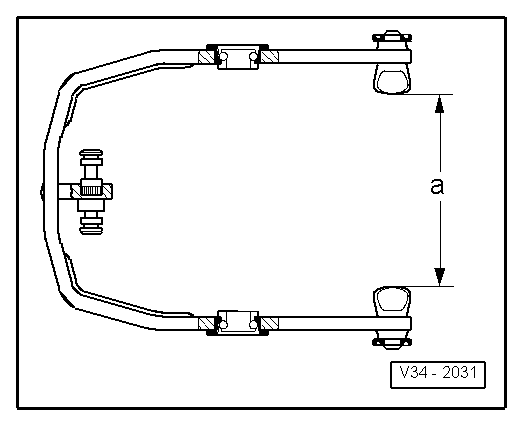

| q | Dimensions → Fig. |

| 8 - | 1st/2nd gear detent segment |

| q | Identification → Fig. |

| q | The segment must rotate freely after installing the lock washer. |

| 9 - | 3rd/4th gear detent segment |

| q | Identification → Fig. |

| q | The segment must rotate freely after installing the lock washer. |

| 10 - | Sliding piece |

| 11 - | Spring |

| 12 - | Reverse gear selector fork |

| 13 - | Support for reverse gear selector fork |

| 14 - | Circlip |

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|