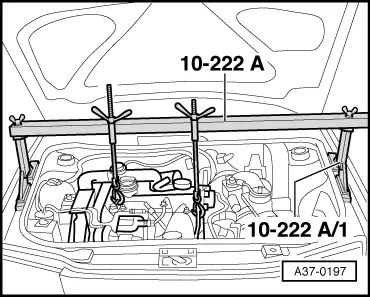

WARNING | Do not remove support bracket -10 - 222 A- until all bolts securing the engine/gearbox mountings (left and right) have been tightened to the specified torque. |

|

| –

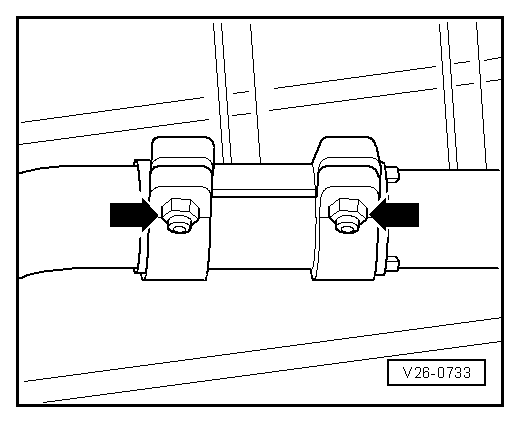

| Assemble exhaust system and align so it is free of stress → Rep. Gr.26. |

| –

| Install engine cover panel. |

Note | When the battery is reconnected, please remember to check and activate the vehicle equipment (radio, clock, convenience electrical systems etc.). |

| –

| Install centre noise insulation (below engine/gearbox) and left noise insulation → Rep. Gr.50. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution WARNING

WARNING