A3 Mk1

| Removing gearbox |

| Special tools and workshop equipment required |

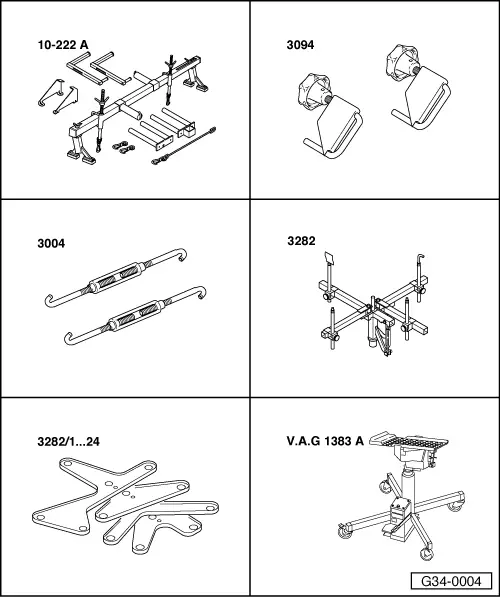

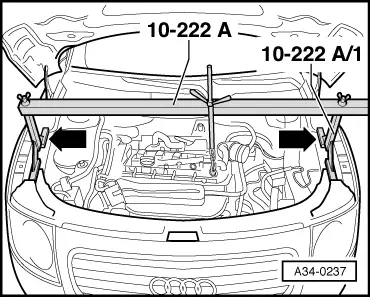

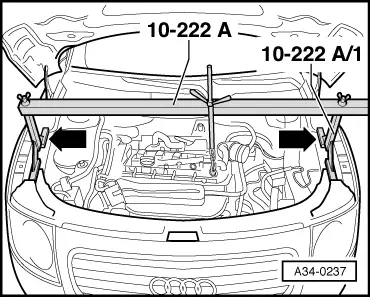

| t | Support bracket -10-222 A- |

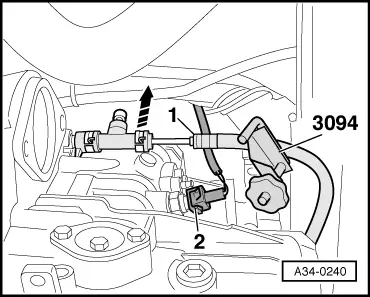

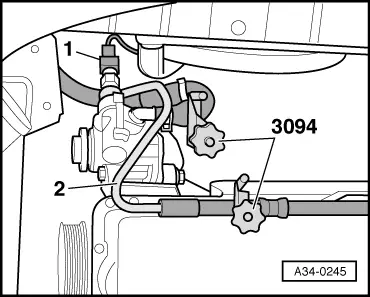

| t | Hose clamps, up to Ø 25 mm -3094- (3x) |

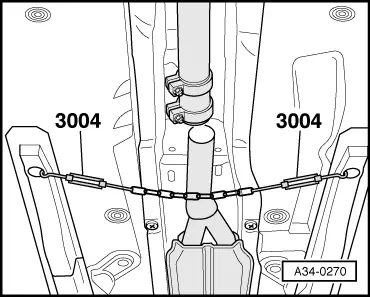

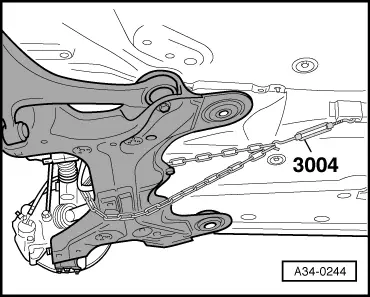

| t | Hooks -3004- (3x) |

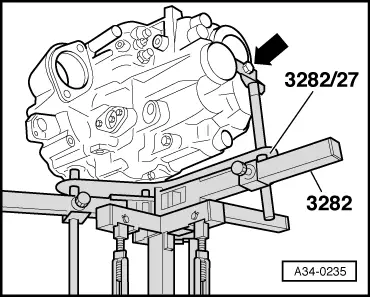

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/27- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Chain (2x) |

Note

Note

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution