| –

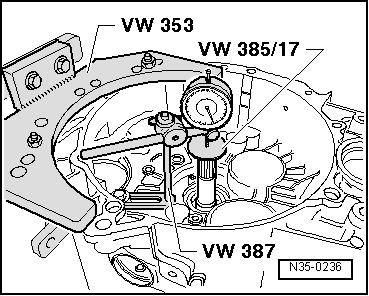

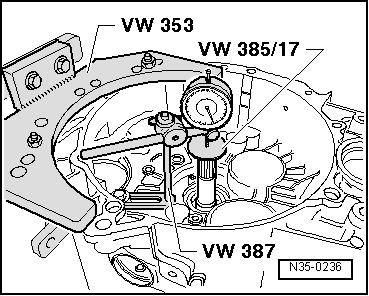

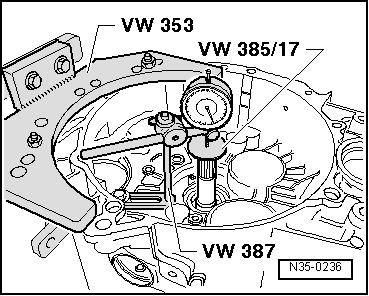

| Fit measuring appliance and dial gauge in clutch housing. |

| –

| Before measurement, rotate input shaft to allow tapered roller bearings to settle. |

| –

| Set dial gauge to “0” with a preload of 1 mm. |

Note | This procedure must be repeated for each subsequent measurement, as otherwise the dial gauge will not return to its original setting. |

| –

| Move input shaft towards dial gauge. |

| –

| Read off and note play indicated on dial gauge (in this example: 1.63 mm). |

| –

| Determine thickness of shim according to following table (in this example: 1.60). |

|

|

|

Note

Note

Note

Note