A3 Mk1

| Dismantling and assembling output shaft for 1st - 4th gear |

| Special tools and workshop equipment required |

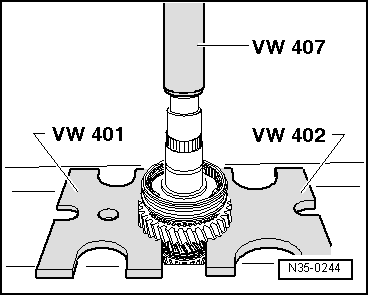

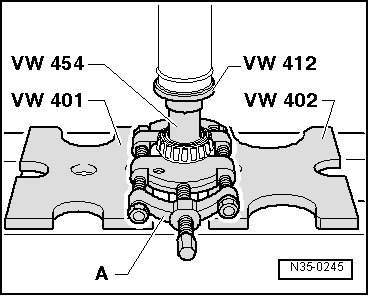

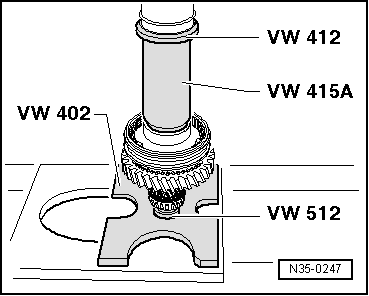

| t | Thrust plate -VW 401- |

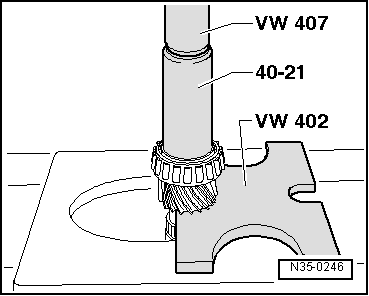

| t | Thrust plate -VW 402- |

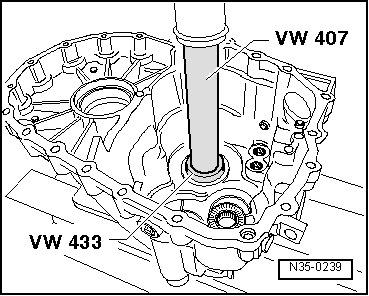

| t | Press tool -VW 407- |

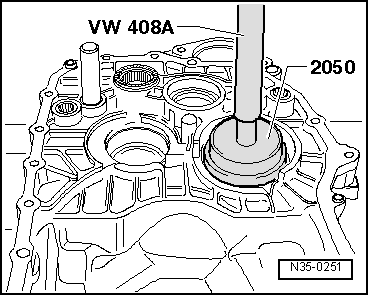

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

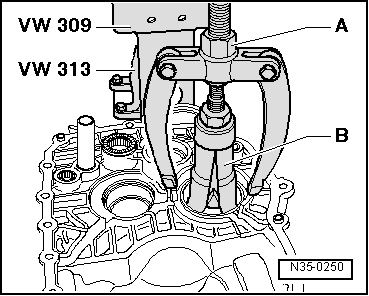

| t | Support plate -VW 309- |

| t | Support clamp -VW 313- |

| t | Gearbox support -VW 353- |

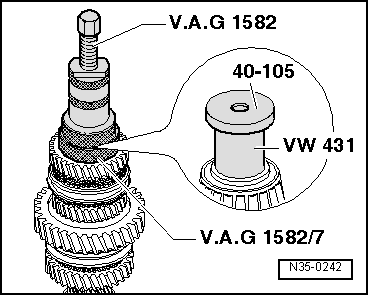

| t | Press tool -VW 431- |

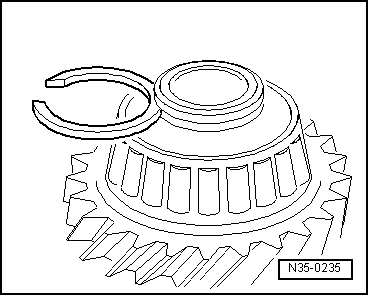

| t | Press tool -VW 433- |

| t | Press tool -VW 454- |

| t | Thrust plate -VW 512- |

| t | Tube -VW 516- |

| t | Tube -VW 519- |

| t | Multi-purpose tool -VW 771- |

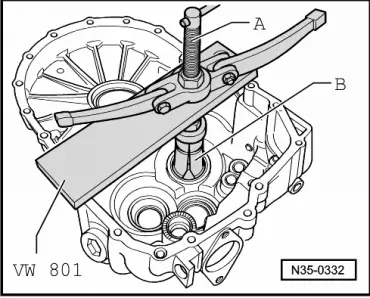

| t | Support plate -VW 801- |

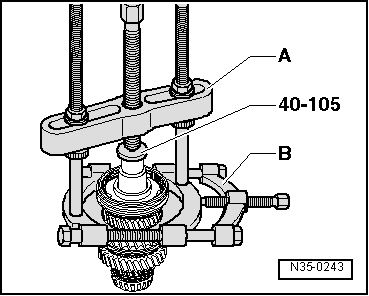

| t | Thrust plate -40-105- |

| t | Drift sleeve -40-20- |

| t | Drift sleeve -40-21- |

| t | Thrust piece -2050- |

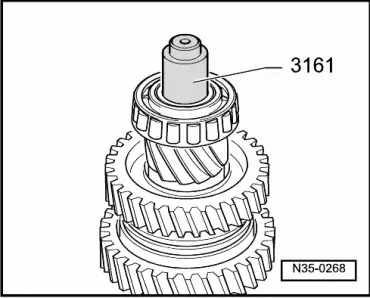

| t | Extension -3161- |

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/7- |

|

|

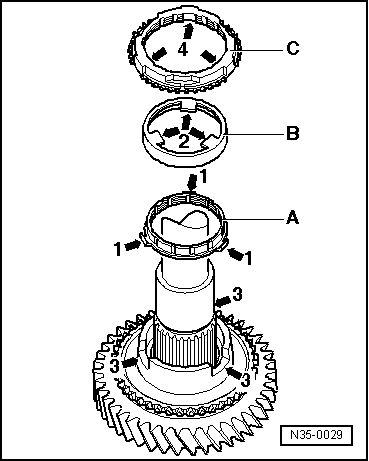

| Output shaft for 1st - 4th gear - exploded view of components |

Note

Note| t | Refer to technical data → Chapter when installing new gears or a new output shaft. |

| t | Adjust output shaft after renewing output shaft or tapered roller bearings → Chapter. |

| 1 - | Clutch housing |

| 2 - | Oil deflector plate |

| 3 - | Dished washer |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 4 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 5 - | Tapered roller bearing inner race |

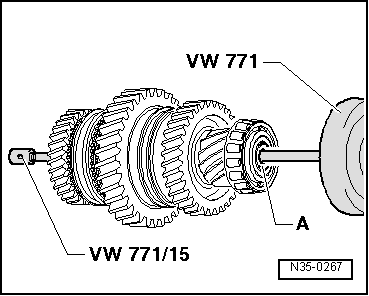

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 6 - | Output shaft |

| q | For 1st to 4th gear |

| q | Adjusting → Chapter |

| 7 - | Needle bearing |

| q | For 2nd gear |

| 8 - | 2nd speed selector gear |

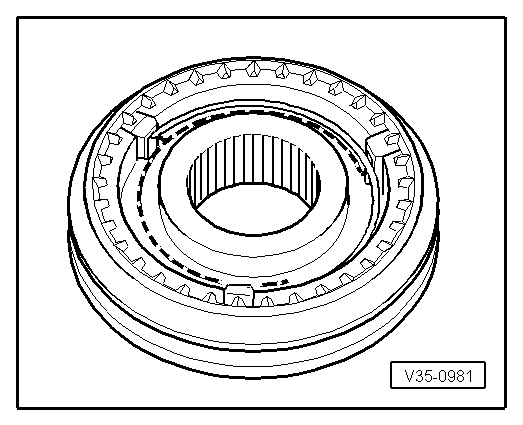

| 9 - | Synchro-ring |

| q | Inner ring for 2nd gear |

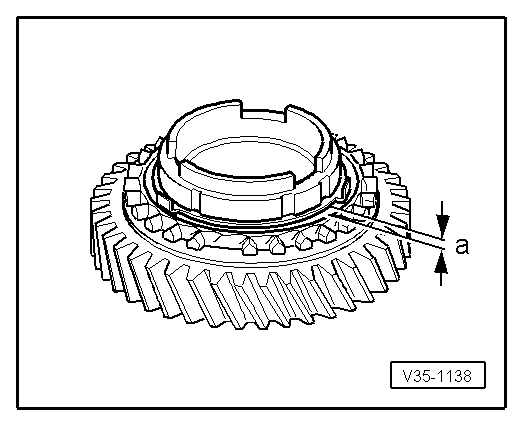

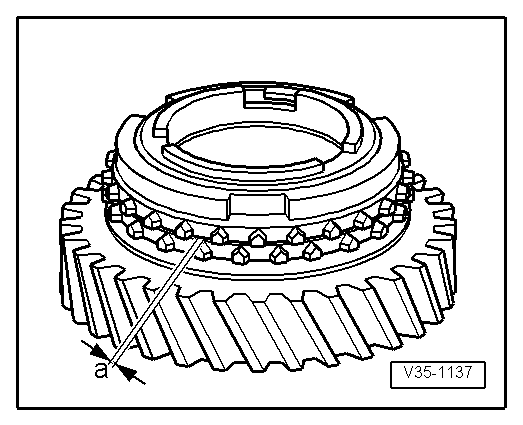

| q | Checking for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 10 - | Outer ring for 2nd gear |

| q | Fit on synchro-ring → Item |

| q | Renew if scored or if there are visible traces of wear |

| q | Installation position → Fig. |

| 11 - | 2nd gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Installation position → Fig. |

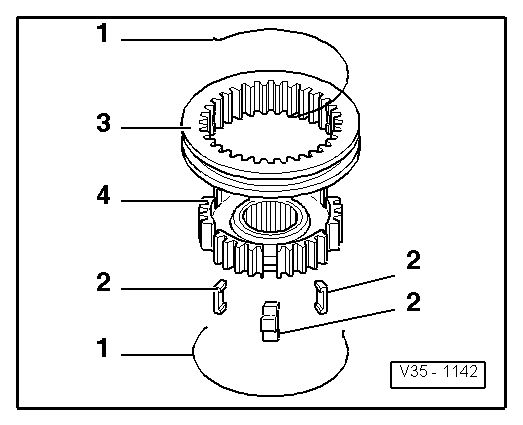

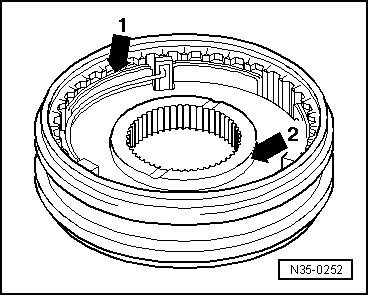

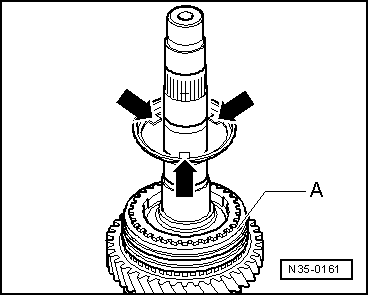

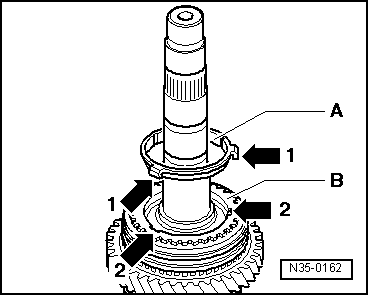

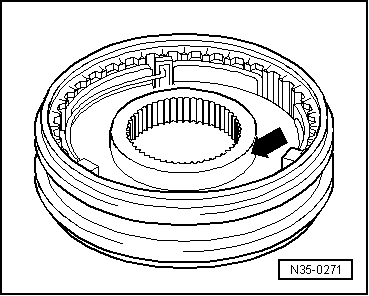

| 12 - | Locking collar with synchronising hub for 1st and 2nd gear |

| q | Press off together with bearing mounting → Fig. after removing circlip → Item |

| q | Dismantling → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. and → Fig. |

| q | Installation position → Fig. |

| q | Pressing on → Fig. |

| 13 - | Circlip |

| 14 - | 1st gear synchro-ring |

| q | Checking for wear → Fig. |

| q | Assemble so that the recesses engage on the locking pieces on the locking collar → Item |

| 15 - | Outer ring for 1st gear |

| q | Insert in synchro-ring → Item; installation position → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 16 - | Synchro-ring |

| q | Inner ring for 1st gear |

| q | Checking for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 17 - | Needle bearing |

| q | For 1st gear |

| 18 - | 1st speed selector gear |

| q | Installation position → Fig. |

| 19 - | Thrust washers |

| q | For 1st and 4th gear |

| q | Insert lugs on thrust washer in hole on output shaft |

| 20 - | Washer |

| q | Holds thrust washers → Item in position on output shaft |

| 21 - | Needle bearing |

| q | For 4th gear |

| 22 - | 4th speed selector gear |

| 23 - | 4th gear synchro-ring |

| q | Checking for wear → Fig. |

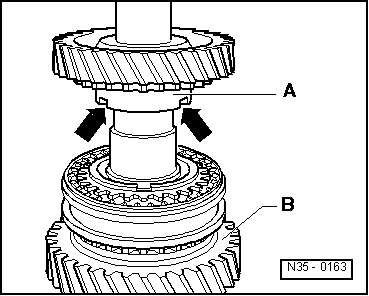

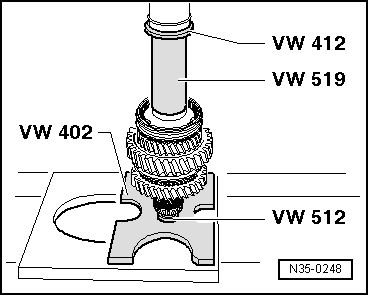

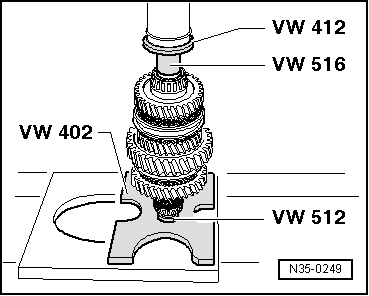

| 24 - | Locking collar with synchronising hub for 3rd and 4th gear |

| q | Pull off together with 4th speed selector gear after removing circlip → Item → Fig. |

| q | Dismantling → Fig. |

| q | Installation position: Locking collar/synchronising hub → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. and → Fig. |

| q | Pressing on → Fig. |

| 25 - | Circlip |

| 26 - | 3rd gear synchro-ring |

| q | Checking for wear → Fig. |

| 27 - | Outer ring for 3rd gear |

| q | Insert in synchro-ring → Item; installation position → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 28 - | Synchro-ring |

| q | Inner ring for 3rd gear |

| q | Checking for wear → Fig. |

| q | Check lugs for scoring |

| q | Installation position → Fig. |

| 29 - | Needle bearing |

| q | For 3rd gear |

| 30 - | 3rd speed selector gear |

| q | Installation position → Fig. |

| 31 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

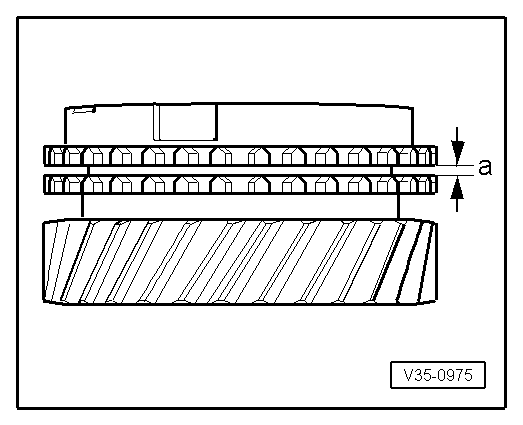

| 32 - | Circlip |

| q | When tapered roller bearing → Item or output shaft → Item are renewed: determine thickness of required circlip → Fig. |

| 33 - | Tapered roller bearing outer race |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 34 - | Shim |

| q | Determining thickness → Chapter |

| 35 - | Gearbox housing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Circlips available (in mm) → Note | ||

| 1.79 | 1.89 | 1.98 |

| 1.83 | 1.92 | |

| 1.86 | 1.95 | |

|

|

|

|

|