A3 Mk1

|

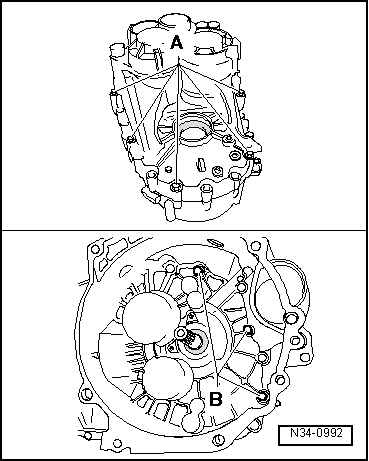

Adjusting output shaft for 1st-4th gears

Adjusting output shaft for 1st-4th gears

|

|

|

|

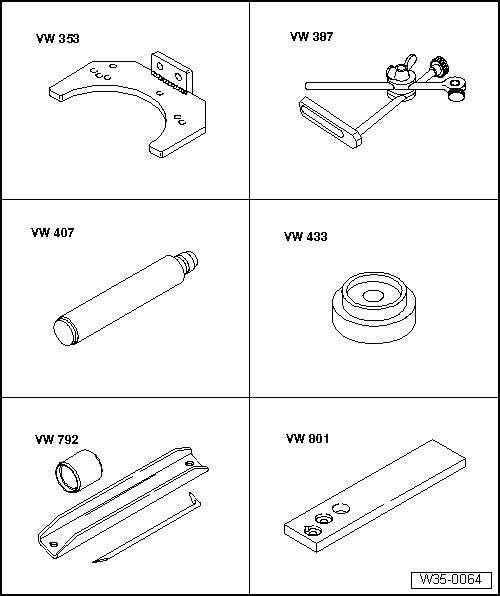

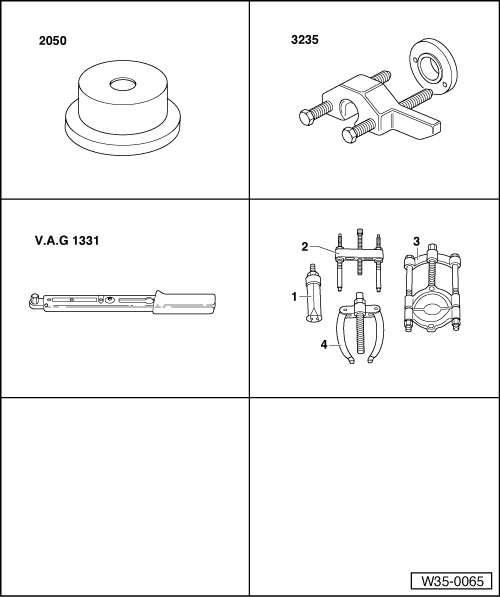

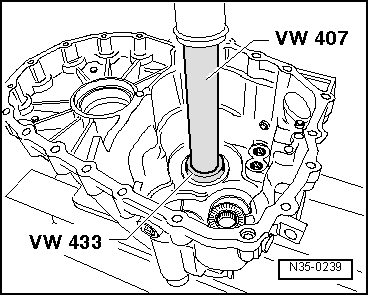

Special tools and workshop equipment required

It is necessary to readjust the output shaft when the following components are renewed:

or

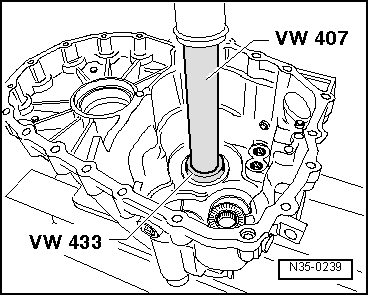

Adjustment overview Prerequisites

|

|

|

|

|

|

|

|

||||||||

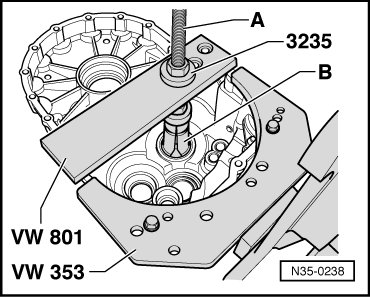

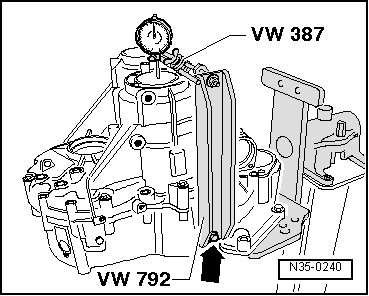

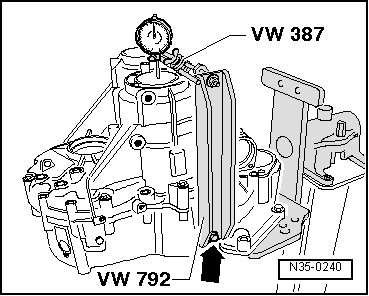

Note: If dial gauge indicates no value when clutch housing/gearbox housing securing bolts are loosened, install shim 1.95 mm (part No. 084 409 383 AS) or, if necessary, shim 2.20 mm (part No. 084 409 383 BD). Determining thickness of shim The specified bearing pretension will be attained by subtracting the measured value (0.14 mm) from the inserted shim (1.70 mm) and adding a constant for pressing (0.20 mm). Example:

|

|

|

Carry out check measurement |

|

|

|