| l

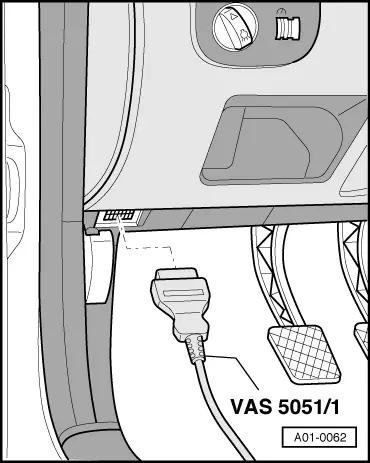

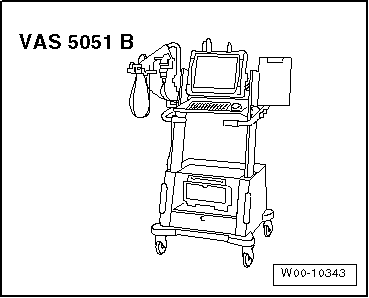

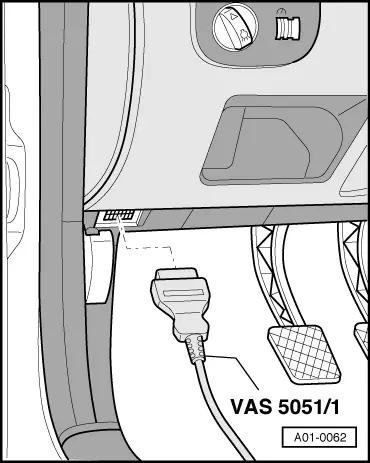

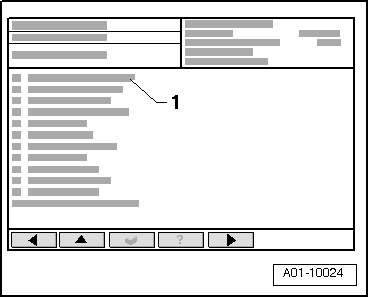

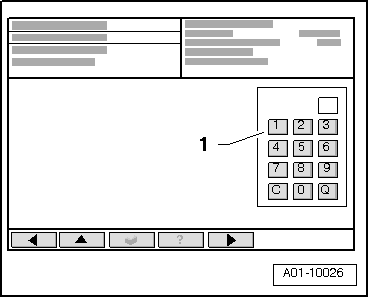

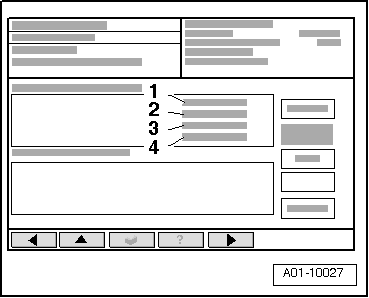

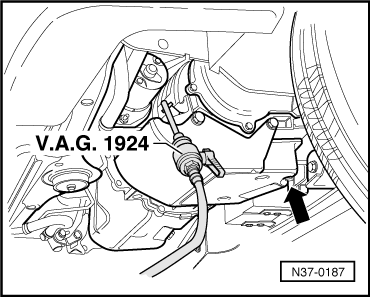

| Vehicle diagnostic, testing and information system -VAS 5051B- connected up; Vehicle self-diagnosis and vehicle system 02 - Gearbox electronics selected. |

| l

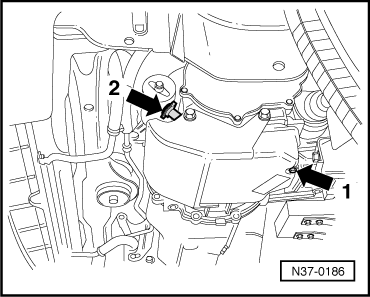

| The ATF temperature at the beginning of the test must not be higher than 35 °C. If necessary, first allow the gearbox to cool down. |

Note | t

| The ATF level will vary according to the ATF temperature. |

| t

| If the ATF level is checked when the ATF temperature is too low, this will result in overfilling. |

| t

| If the level is checked when the ATF temperature is too high, this will result in underfilling. |

| t

| Both overfilling and underfilling will impair the function of the gearbox. |

| t

| The ATF temperature is taken from the reading on the vehicle diagnostic, testing and information system -VAS 5051B-. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING