A3 Mk1

|

Removing and installing parts of the lubrication system

Removing and installing oil pan

|

|

|

|

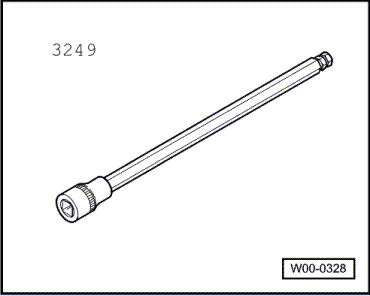

Special tools and workshop equipment required

=> Parts List |

|

|

|

Removing

|

|

|

|

|

|

|

|

|

|

|

|

|

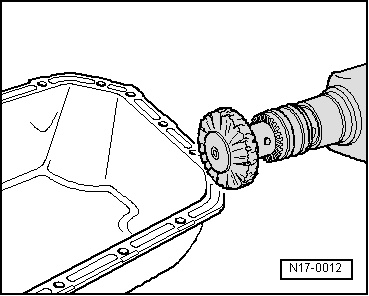

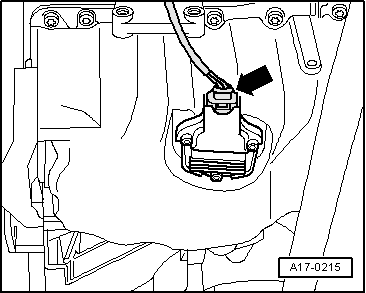

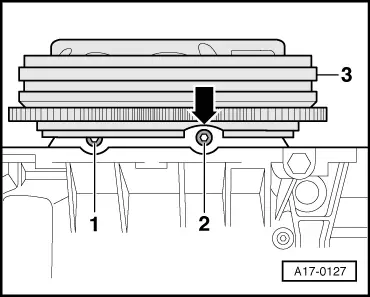

Note: → The two rear oil pan bolts -1- and -2- are accessible via the recess -arrow- on the flywheel -3- (turn the flywheel as required). |

|

|

|

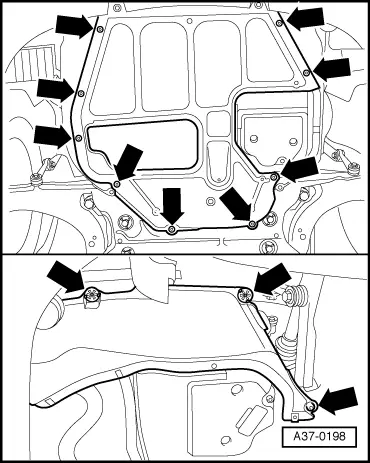

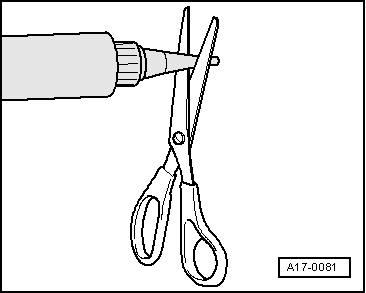

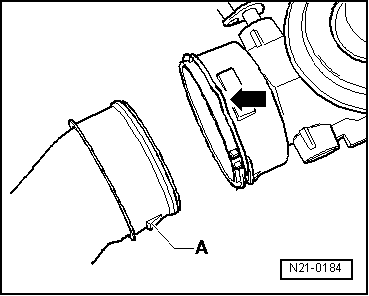

Note: The sump must be installed within 5 minutes after applying the silicone sealant.

|

|

|

|

Note: The bead of sealant must not be thicker than 3 mm, as otherwise excess sealant will enter the sump and obstruct the strainer in the oil intake manifold.

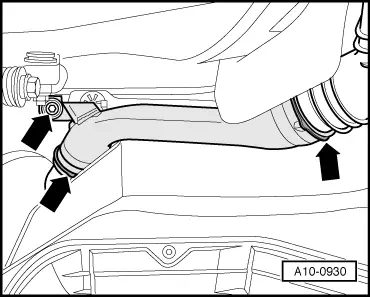

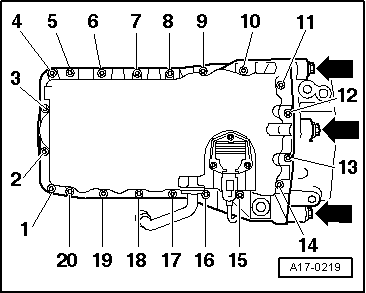

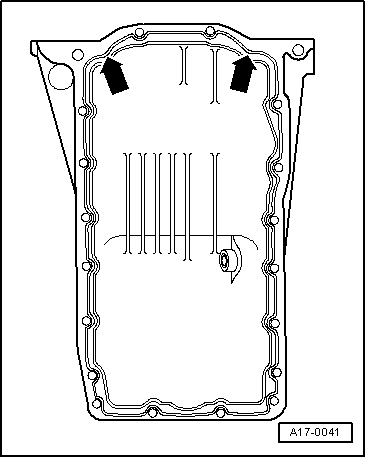

Note: Be particularly careful when applying the bead of sealant around the rear sealing flange (arrows in illustration). |

|

|||||||||||||

Tightening torques

|