A3 Mk1

| Removing engine |

| t | Drip tray for workshop hoist -VAS 6208- or -V.A.G 1306- |

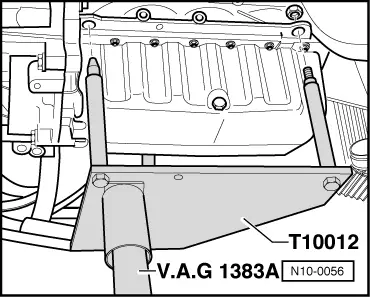

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Stepladder -VAS 5085- |

| t | Engine bracket -T10012- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

WARNING

WARNING Caution

Caution