| –

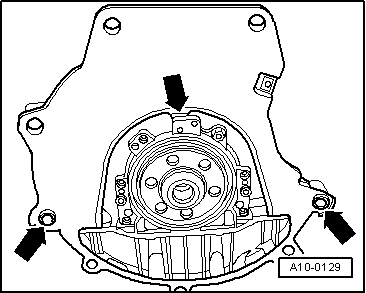

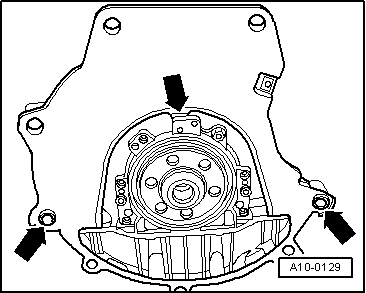

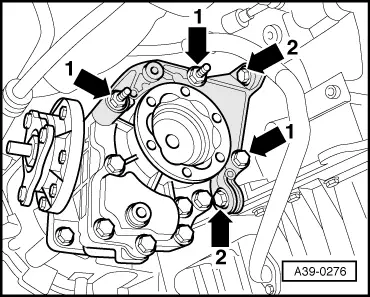

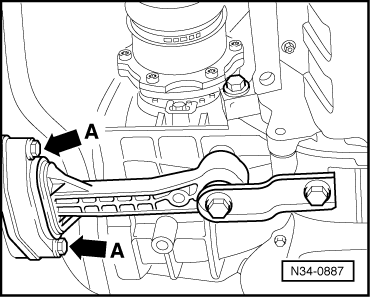

| Engage intermediate plate on sealing flange and slip onto dowel sleeves -arrows-. |

| –

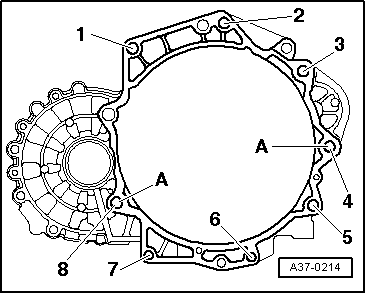

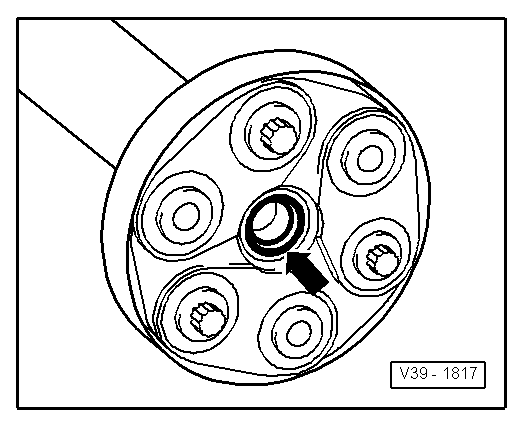

| Check that clutch plate is correctly centred. |

| –

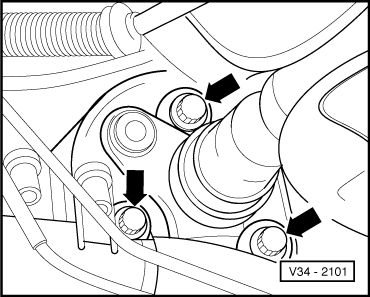

| Check clutch release bearing for wear, renew if necessary. |

| –

| Lightly grease clutch release bearing, release bearing guide sleeve and splines on input shaft with grease for clutch plate splines -G 000 100-. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine oil or gearbox oil may be used, but do not use lubricant containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15 %. |

| –

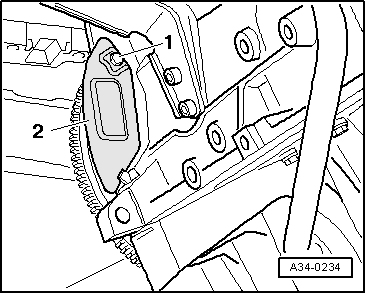

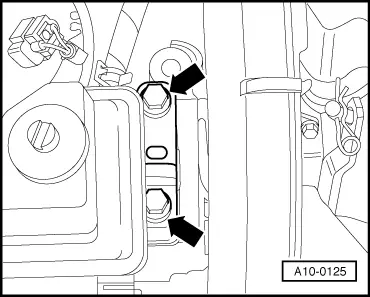

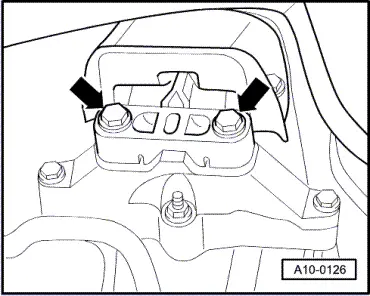

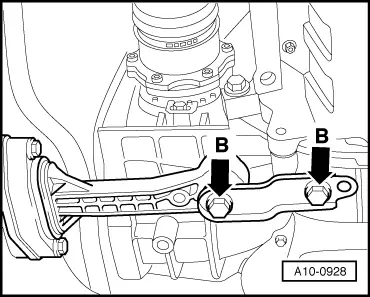

| Fit bracket for bevel box before fitting engine/gearbox securing bolts. |

| –

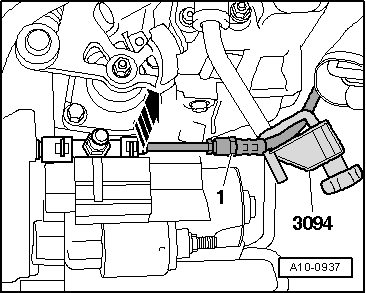

| Use new securing bolts. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note

Caution

Caution