A3 Mk1

|

Removing and installing engine

Installing

Special tools and workshop equipment required

Work sequence

Installation is carried out in the reverse sequence, when doing this note the following: Notes:

=> Parts catalogue

|

|

|

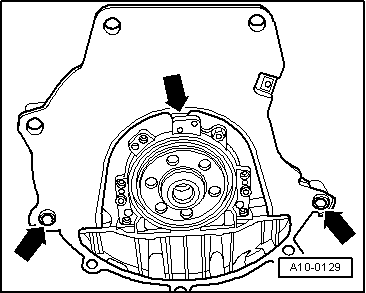

Vehicles with manual gearbox

Notes:

|

|

|||||||||||||

|

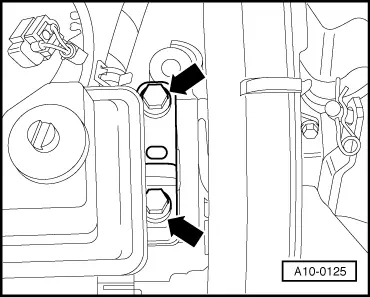

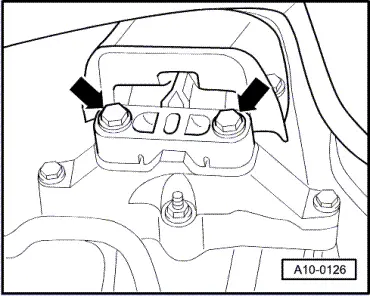

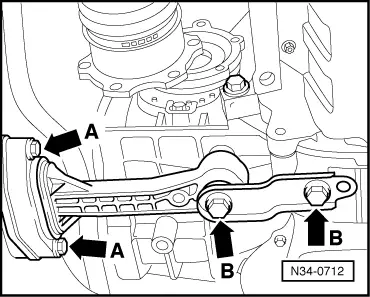

→ Engine/gearbox mountings (manual gearbox)

1) Bolt with M8 stud A: centering sleeves |

|

|

|

|

|

|

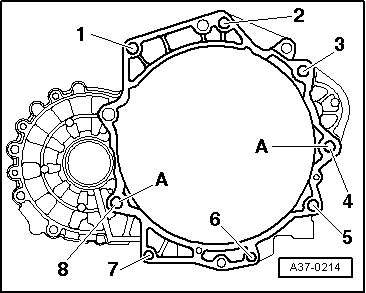

Vehicles with automatic gearbox

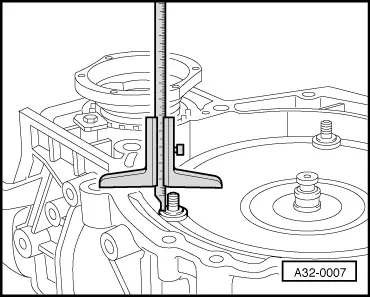

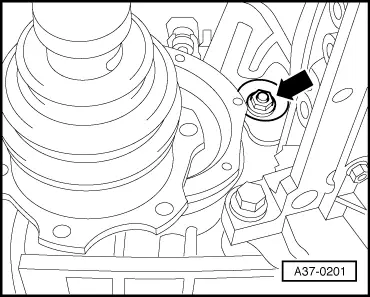

=> Parts catalogue → If the torque converter is correctly installed, the depth between the contact faces at the bottom of the studs on the torque converter and the contact surface of the torque converter bell housing is about 22 mm. If the torque converter is not fully inserted, this distance is about 10 mm. Important!

If the torque converter is incorrectly inserted, the driver of the torque converter or the ATF pump will be severely damaged when the gearbox is attached to the engine. |

|

|

Notes:

|

|

||||||||||||||||

|

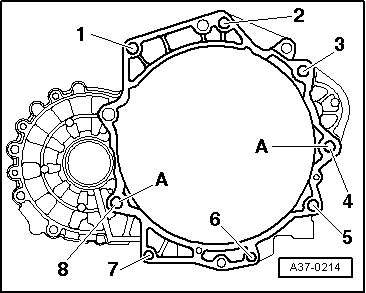

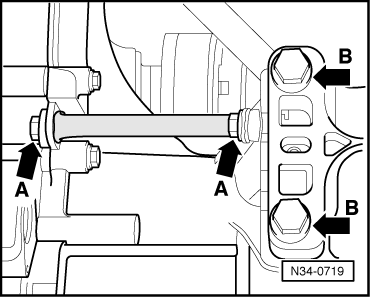

→ Engine/gearbox mountings (automatics)

1) Bolt with M8 stud A: centering sleeves |

|

|

|

All models

|

|

|

Note: The bolts are only tightened to their final specified torque settings when the engine mountings are adjusted .

=> Running gear, Front-wheel drive and four-wheel drive; Repair group 40 Note: The drive shafts must be installed before doing any more assembly work. |

|

|

Vehicles with manual gearbox

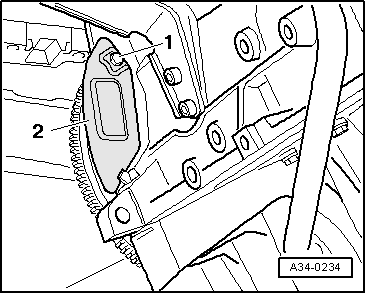

=> 5-Speed manual gearbox 02J; Repair group 30; Servicing clutch release mechanism |

|

|||||||||||||||||||||||||||||||||||||||||||||

All vehicles: The remaining installation steps are carried out in the reverse sequence.

Vehicles with throttle cable:

All models

=> Current flow diagrams, Electrical fault finding and Fitting locations binder Notes:

=> Radio, telephone and navigation system; Repair group 91

=> Motronic injection and ignition system; Repair group 24 Notes:

Warning

Do not use a battery charger to start the engine. Otherwise the electronic control units can be damaged. Tightening torques

1) 90°= 1/4turn 2) Replace nuts or bolts | |||||||||||||||||||||||||||||||||||||||||||||