A3 Mk1

|

Servicing front drive shafts

Removing and installing drive shafts

|

|

|

|

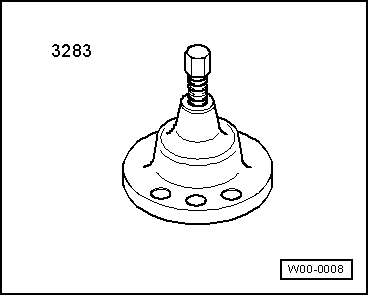

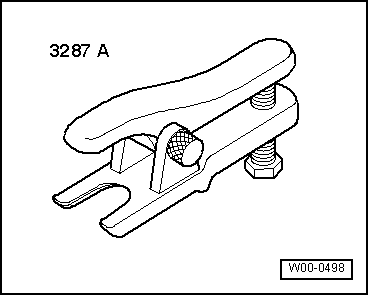

Special tools and workshop equipment required

|

|

|

Removing

|

|

|

|

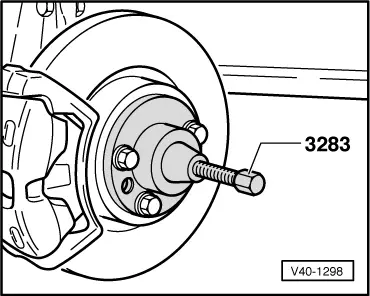

Audi A3:

|

|

|

|

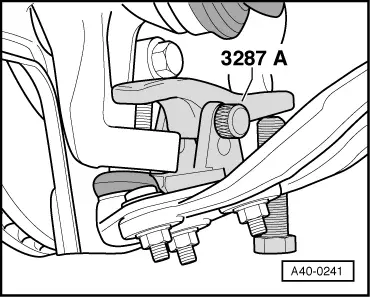

Audi S3:

|

|

|

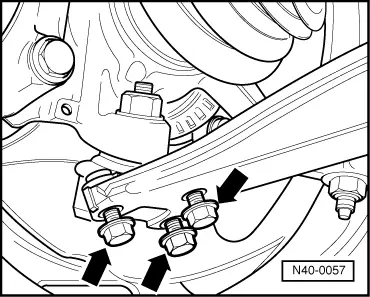

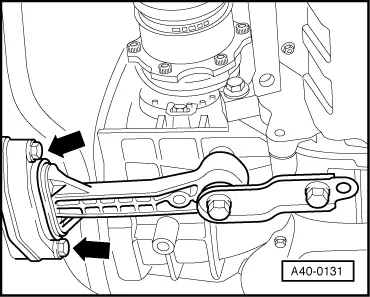

Note: Leave nut screwed several turns onto ball joint to protect thread.

Attention:

On pressing out, ball joint is abruptly released from wheel bearing housing and can be a source of danger. |

|

|

|

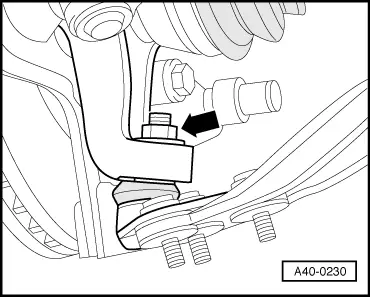

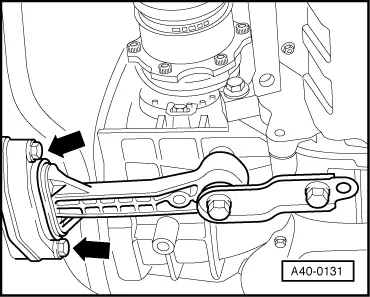

All models:

Note: Ensure adequate clearance when pressing out drive shaft. |

|

|

|

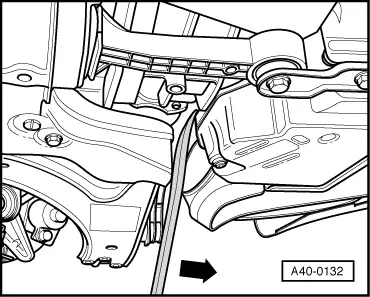

Vehicles with automatic gearbox:

|

|

|

All models:

|

|

|||||||||||||

|

Installing Install in reverse order, paying attention to the following: Vehicles with automatic gearbox:

All models:

Tightening torques

1) Replace bolts 2) 90°corresponds to quarter turn Perform wheel alignment on Audi A3 after installation. | |||||||||||||