A3 Mk1

|

Servicing rear axle - Four-wheel drive vehicles

Removing and installing subframe with final drive

|

|

|

|

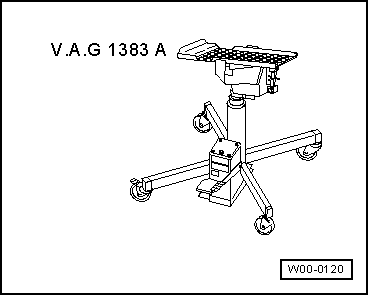

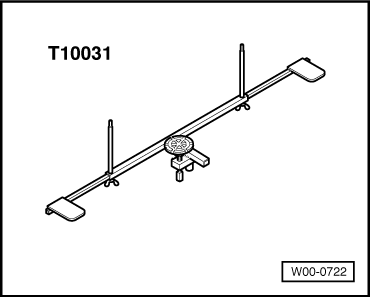

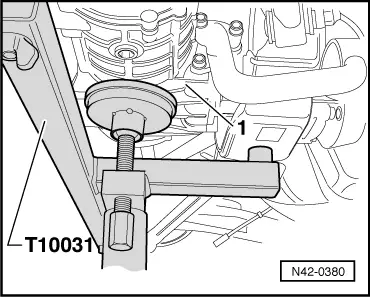

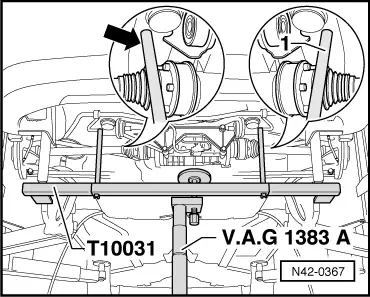

Special tools and workshop equipment required

|

|

|

|

|

|

|

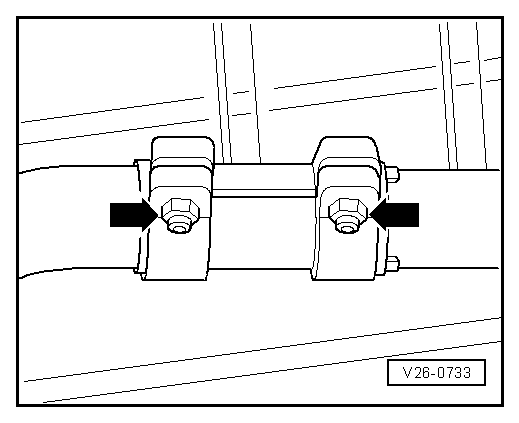

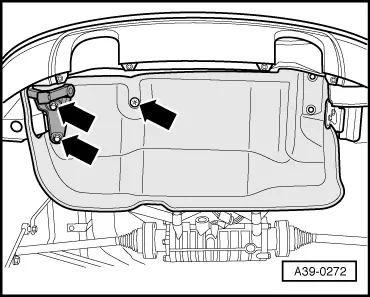

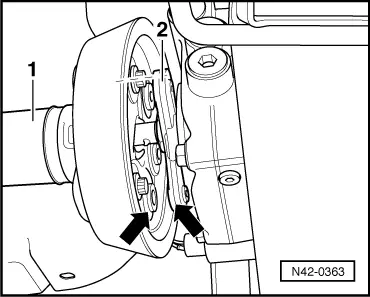

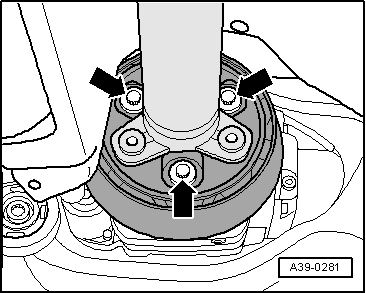

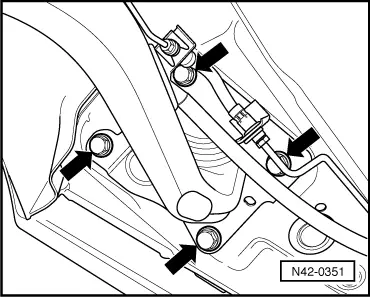

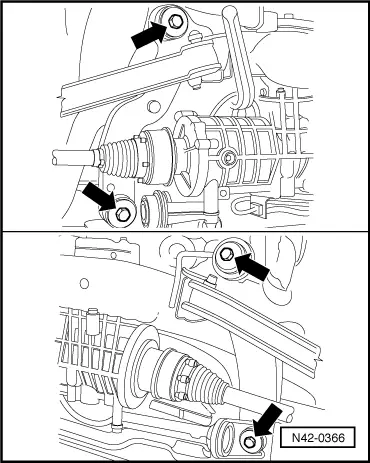

Removing

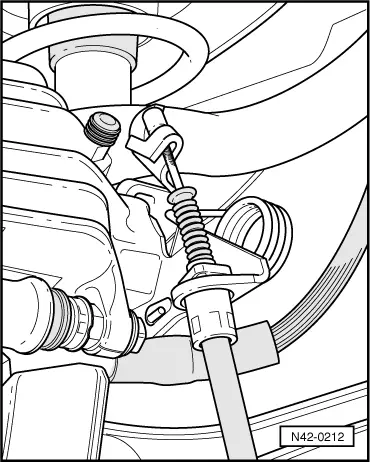

=> Engine, Mechanics; Repair Group 26 Note: To avoid damage, decoupling element of exhaust system is never to be kinked by more than 10 °. |

|

|

|

|

|

|

|

|

|

|

|

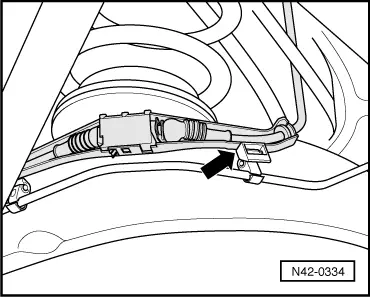

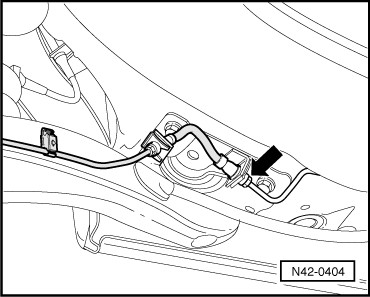

Note: Handbrake cables need not be pulled out of trailing arm if subframe is merely to be lowered. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

Installing Install in reverse order, paying attention to the following:

=> 5-speed Manual Gearbox 02C Four-wheel Drive/Final Drives; Repair Group 39 => 5/6-speed Manual Gearbox 02M Four-wheel Drive/Final Drives; Repair Group 39

=> Engine, Mechanics; Repair Group 26

=> Brake System; Repair Group 47 Tightening torques

1) 90°corresponds to quarter turn 2) Replace bolts Perform wheel alignment after installation. | ||||||||||