A3 Mk2

Note

Note |

|

|

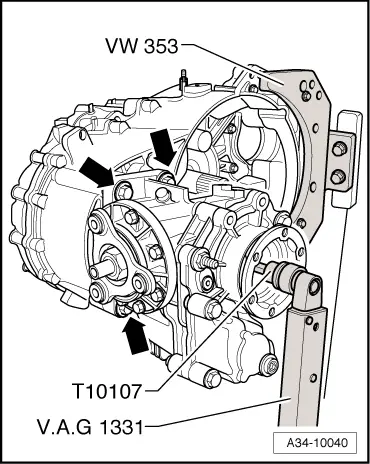

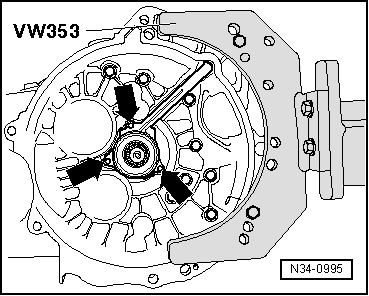

| Special tools and workshop equipment required |

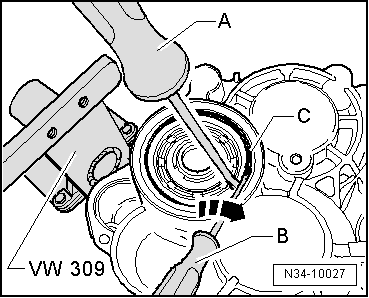

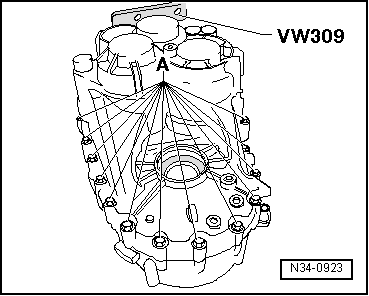

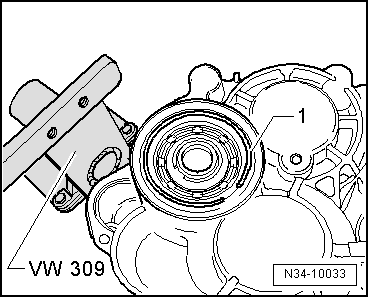

| t | Support plate -VW 309- |

| t | Support clamp -VW 313- |

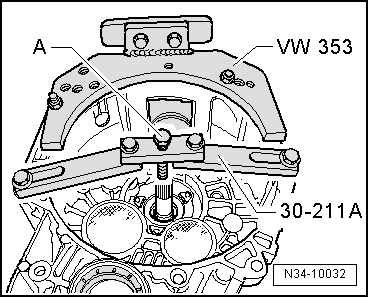

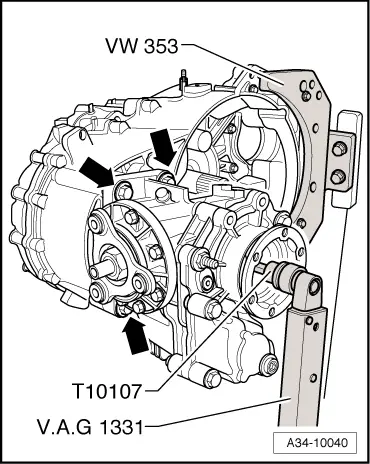

| t | Gearbox support -VW 353- |

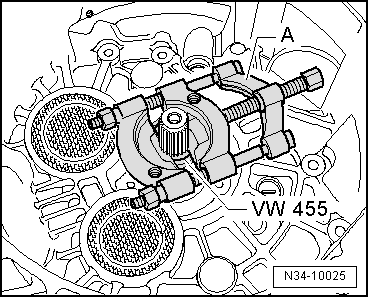

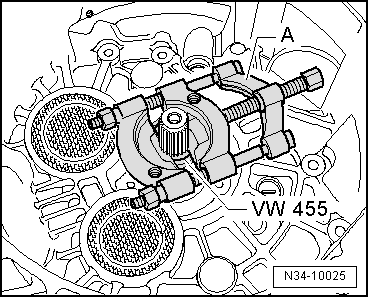

| t | Installing sleeve -VW 455- |

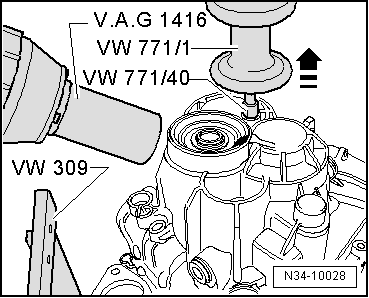

| t | Multi-purpose tool -VW 771- |

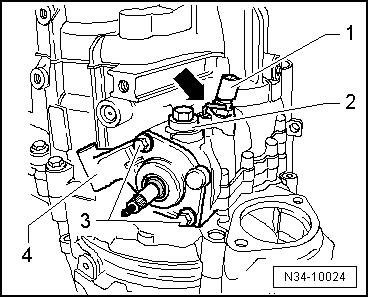

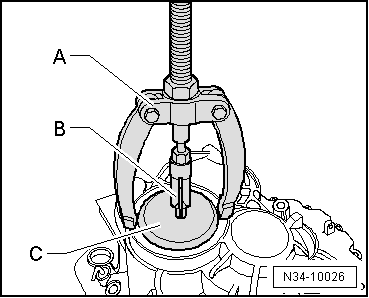

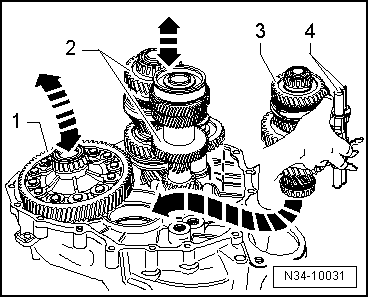

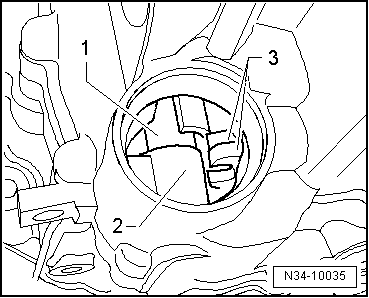

| t | -1- Kukko 21/01 internal puller |

| t | -3- Kukko 17/0 splitter |

| t | -4- Kukko 22/1 counter-support |

| t | Support bridge -30 - 211 A- |

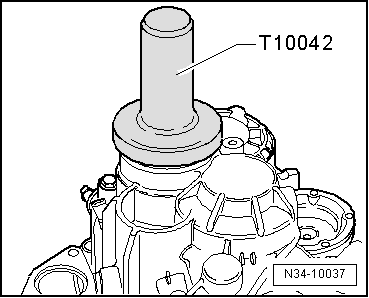

| t | Thrust piece -T10042- |

| t | Drift -T10169- |

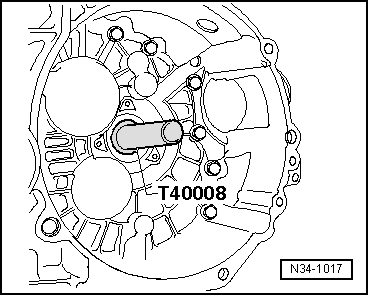

| t | Thrust piece -T40008- |

| t | Torque wrench -V.A.G 1331- |

| t | Hot air blower -V.A.G 1416- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note |

|

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note |

|

|

|

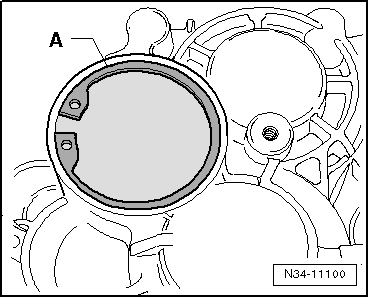

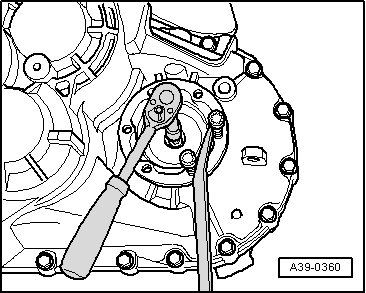

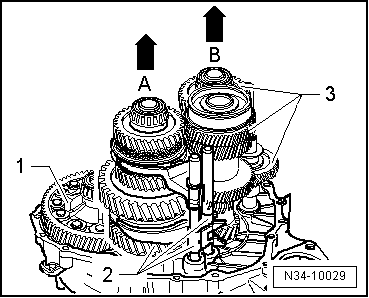

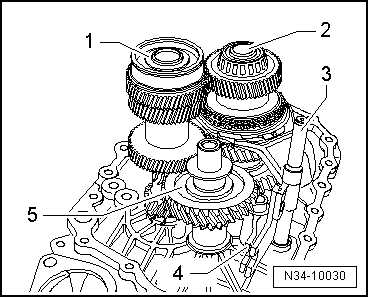

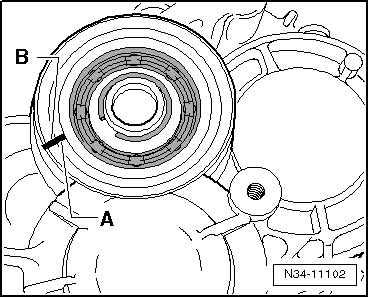

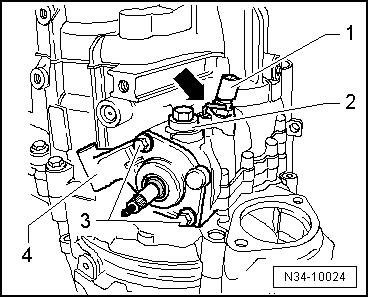

| Grooved ball bearing for input shaft and gearbox housing | ||

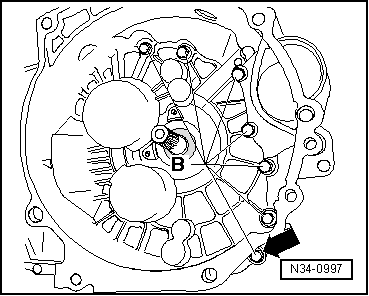

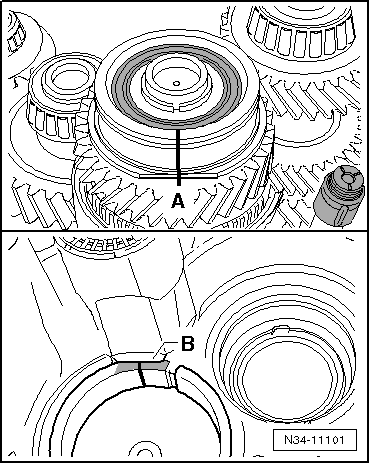

| Without flattened sides on grooved ball bearing -A- and bearing mounting -B- → Anchor | ||

| With flattened sides on grooved ball bearing -A- and bearing mounting -B- → Fig. |

|

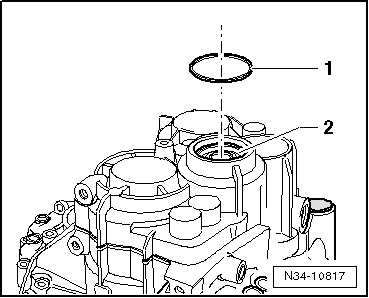

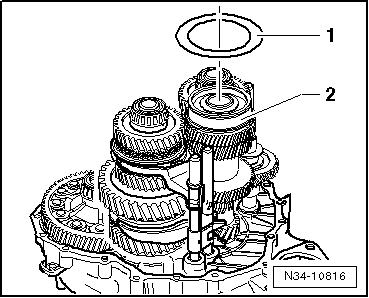

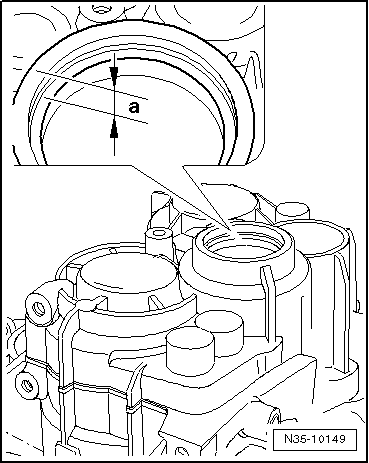

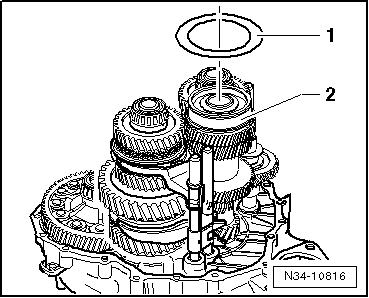

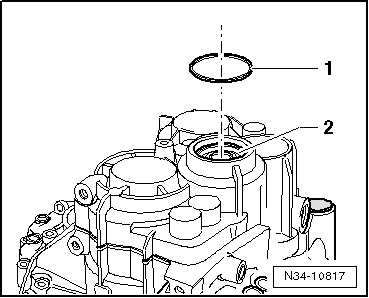

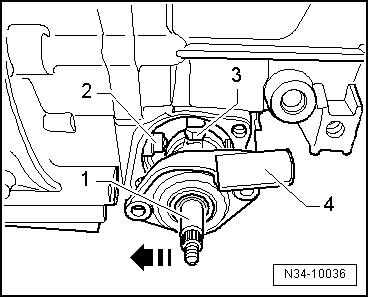

| Top spacer | Outside diameter | 78.6 mm |

| Bottom spacer | Outside diameter | 85 mm |

|

|

| Area above grooved ball bearing | Dimension “a” | Top spacer |

| Up to gearbox manufacturing date 09 04 6 | 10 mm | No |

| From gearbox manufacturing date 10 04 6 onwards | 10.7 mm | Yes |

|

|

| Area below bearing seat | Bottom spacer | |

| Up to gearbox manufacturing date 09 04 6 | Not modified | No |

| From gearbox manufacturing date 10 04 6 onwards | Slightly deeper | Yes |

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Caution

Caution