| l

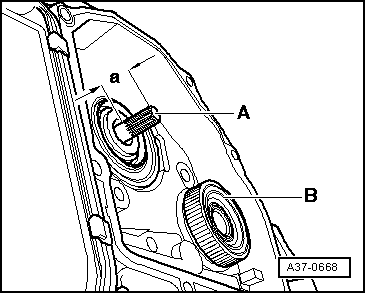

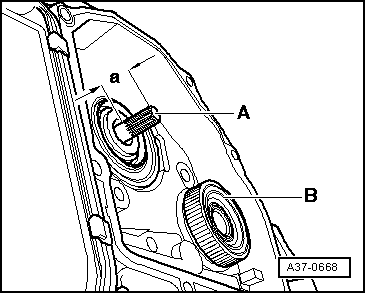

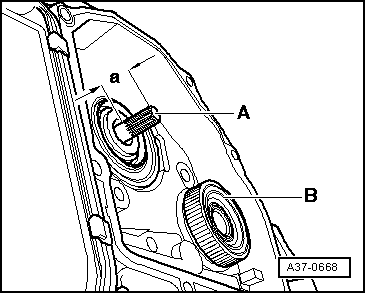

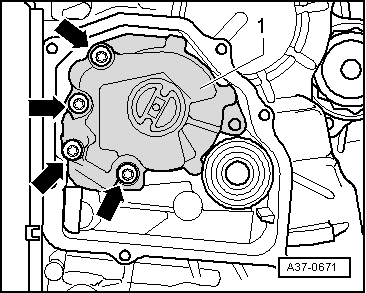

| If drive shaft -A- for gear oil pump is inserted correctly, dimension -a- = approx. 23 mm. |

| –

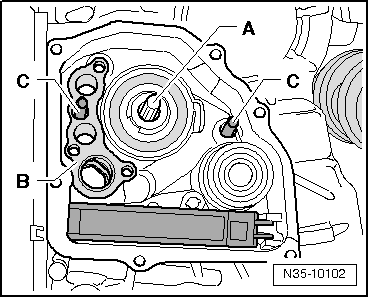

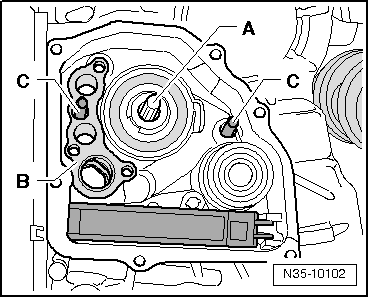

| If necessary, carefully remove any metal particles on sender wheel -B- (the sender wheel must not be demagnetised). |

| –

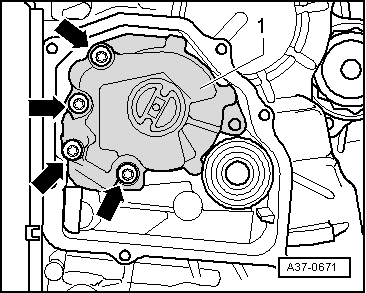

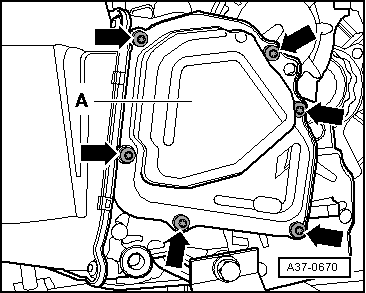

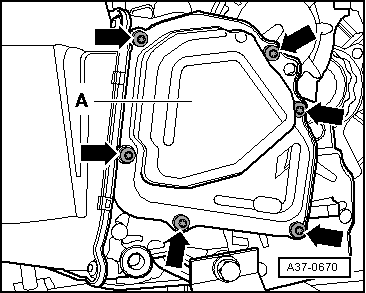

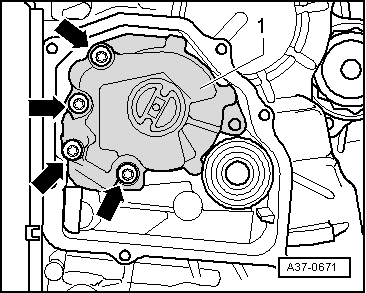

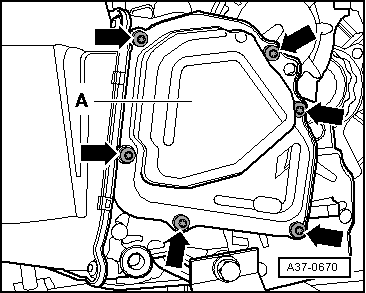

| Remove paper gasket between gear oil pump and gearbox. |

| –

| Remove remaining pieces of paper gasket and clean inside of gearbox. |

| –

| Clean sealing surfaces; they must be free from oil and grease. |

| –

| Fit new paper gasket between gear oil pump and gearbox, if necessary, apply gear oil to hold it in place while assembling. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note