A4 Cabriolet Mk2

| Removing gearbox - vehicles with 8-cyl. FSI engine (Audi RS 4) |

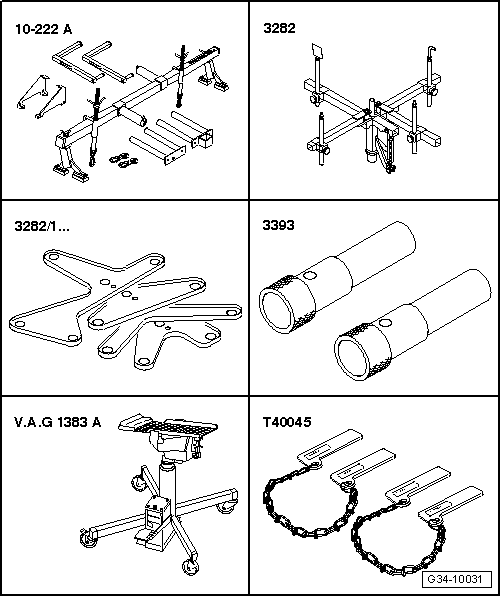

| Special tools and workshop equipment required |

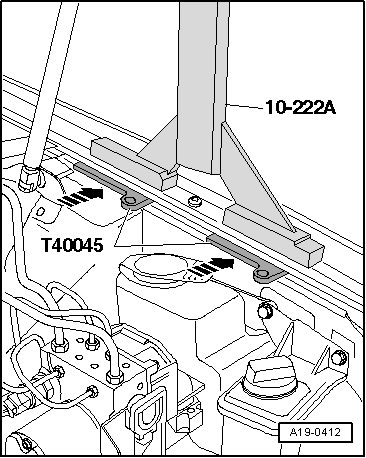

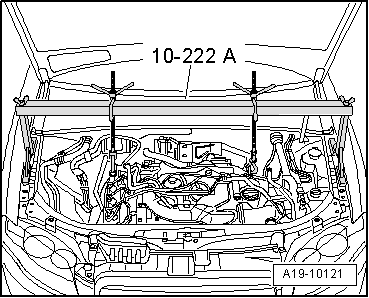

| t | Support bracket -10-222 A- |

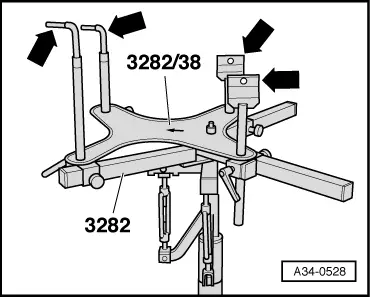

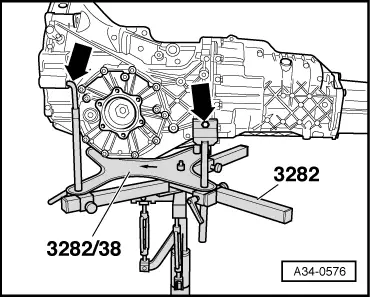

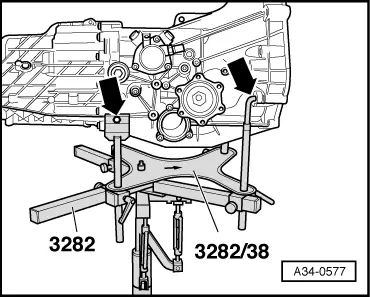

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/38- |

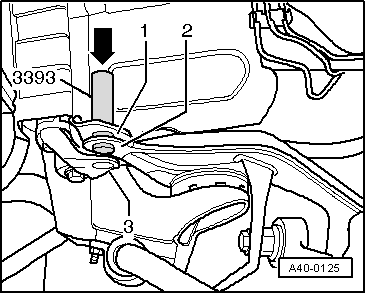

| t | Locating pins -3393- |

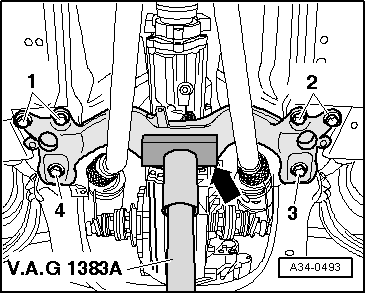

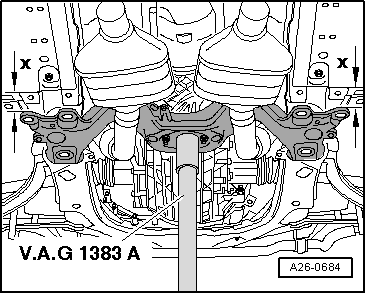

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Wing compensation plates -T40045- |

| t | Drill Ø 10.2 mm |

| t | Bolt M10x20 (2x) |

| t | Copper grease -Z 381 351 TE- |

| t | Grease for clutch plate splines -G 000 100- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING