A4 Mk1

|

Adjusting drive pinion and crown wheel

Adjusting drive pinion

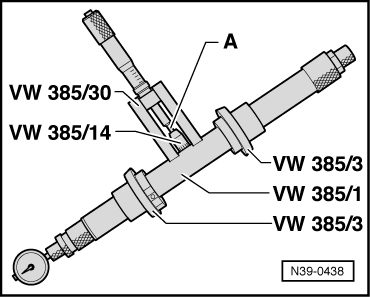

Repairs after which the pinion shaft must be adjusted => table on Page 39-39. Special tools, testers and auxiliary equipment required

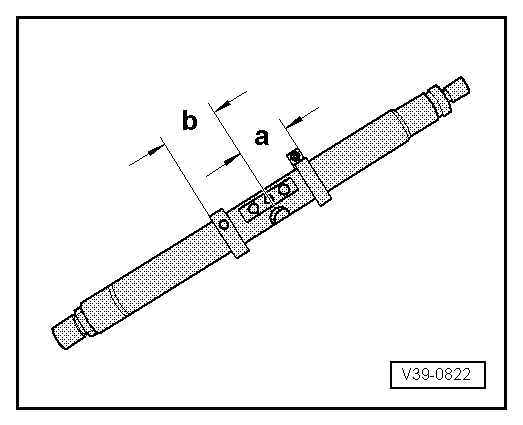

Determining total shim thickness "Stotal" for shims "S3" + "S4" |

|

|

|

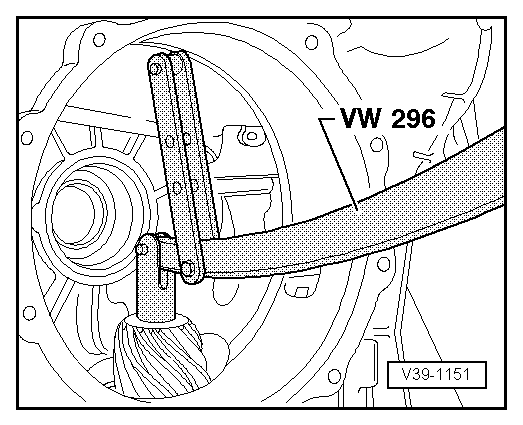

(Setting preload of taper roller bearing for drive pinion)

Note: Illustration shows pinion shaft without gearwheels. |

|

||||||||||

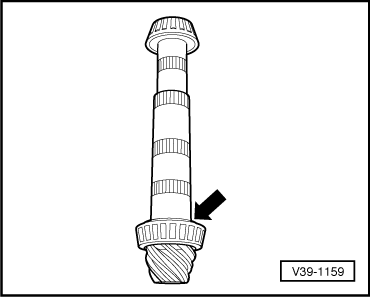

Thrust plates and rubber washers with different thicknesses can be installed:

|

|

|

Note: For measurement purposes a shim "S4" with a thickness of 1.0 mm is initially inserted It is referred to as "S4*" in the following. After determining measurement "e", "S4*" will be replaced by the correct shim "S4".

|

|

|

|

|

|

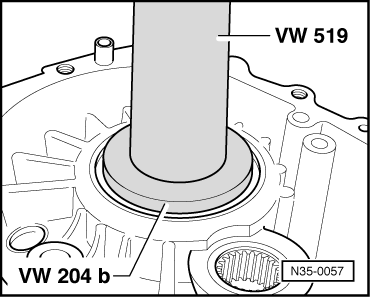

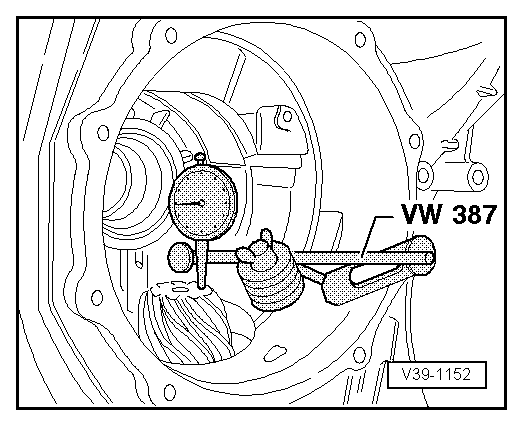

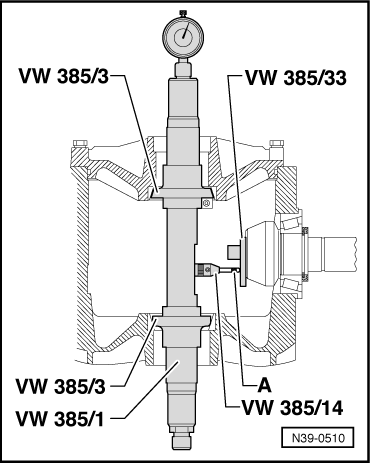

Note: The dial gauge extension must contact the machined surface on the face of the pinion.

|

|

|||||||||||||||||||||||||||||||||||||||||

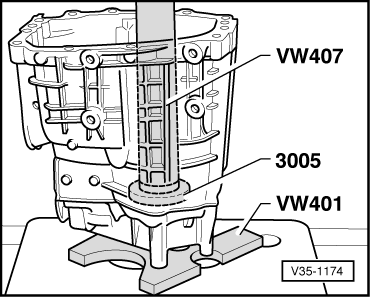

Note: If the measurement has to be repeated, the pinion shaft must first be rotated another 5 turns in each direction to settle the taper roller bearing. Reset dial gauge to "0" with 2 mm preload.

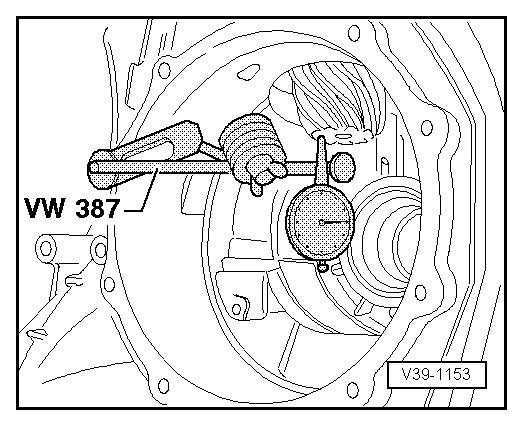

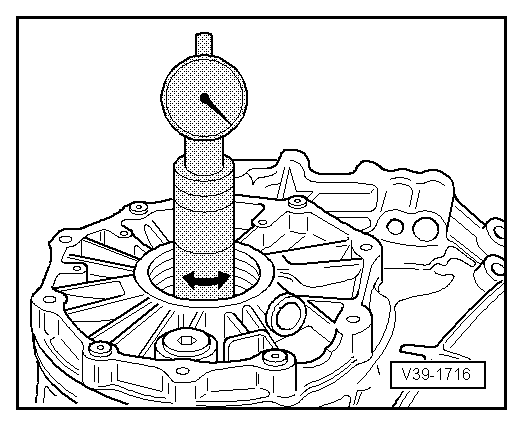

Determining thickness of shim "S3*"

Checking preload of taper roller bearing for drive pinion

Notes:

| |||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||

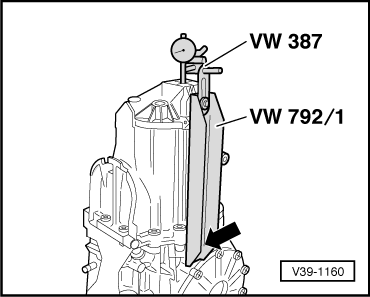

Note: On gearboxes with flange shafts without polygon bearings (=>from Page 00-3), use centring disc VW 385/2 instead of centring disc VW 385/3 opposite the dial gauge. |

|

|

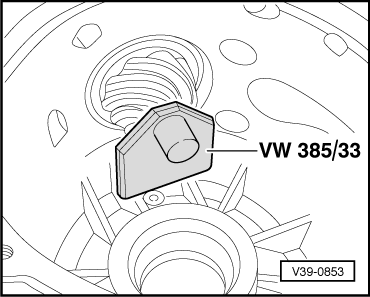

Note: Ensure plate contact surface fits exactly and is free of oil. |

|

|

|

|

|

Note: Then, (after removing universal mandrel) check again that the dial gauge, with master gauge VW 385/30 or VW 385/15 in place, indicates "0" with 2 mm preload. Otherwise correct adjustments. |