|

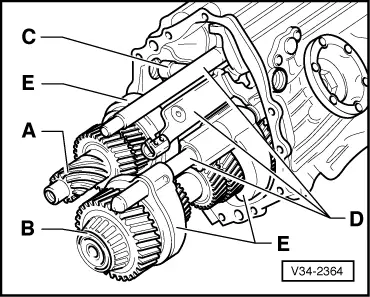

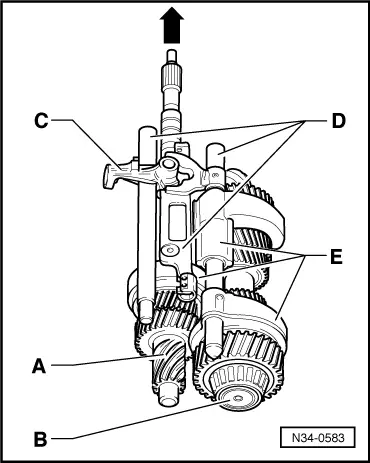

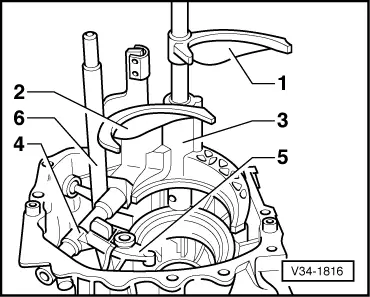

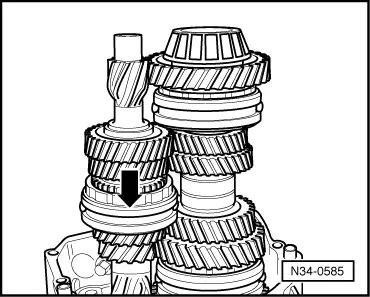

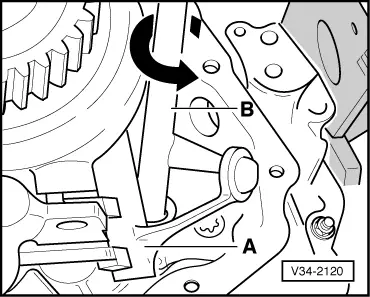

Dismantling and assembling gearbox

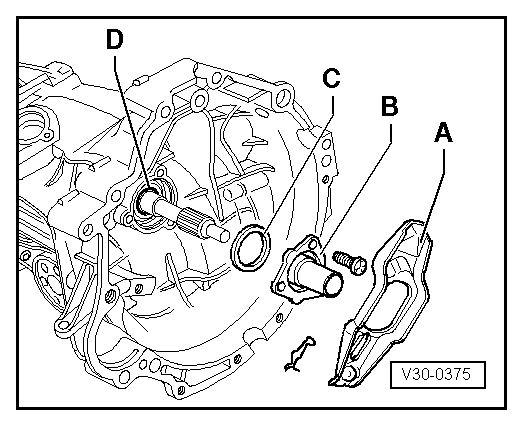

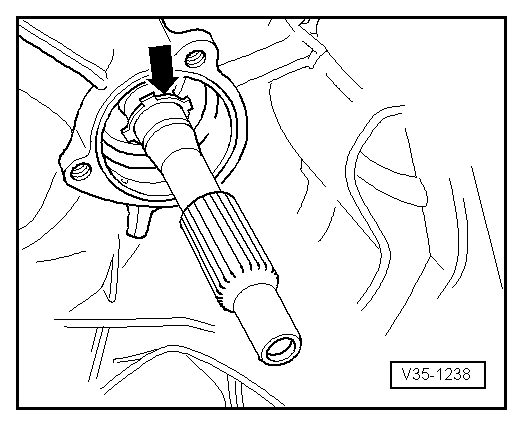

Removing and installing input shaft ball bearing, multi-function sender, input shaft, pinion shaft, selector rods and gearbox cover

Notes:

-

◆ It is not necessary to remove the differential to remove the above-mentioned components.

-

◆ Removal is only necessary when adjustments have to be carried out => adjustment overview, Page 39-39.

Special tools, testers and auxiliary equipment required

-

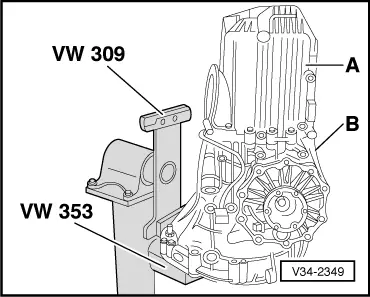

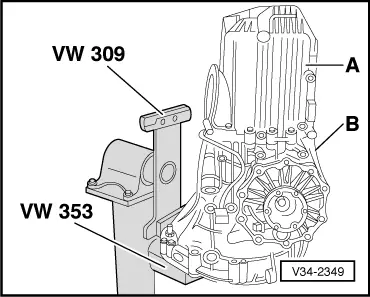

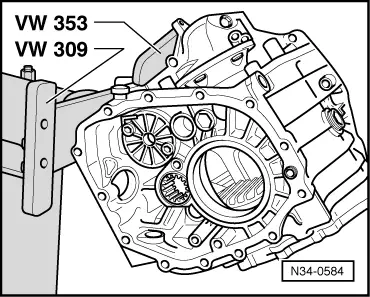

◆ Holding plate VW 309

-

◆ Gearbox support VW 353

-

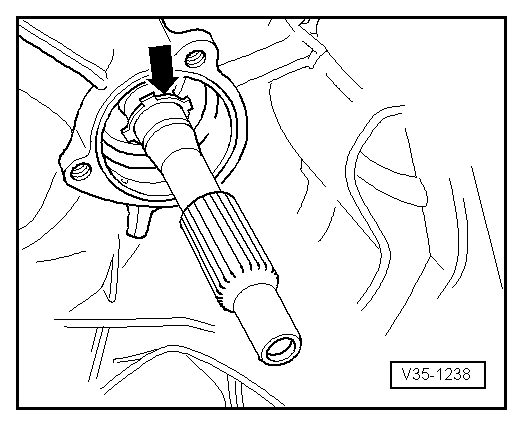

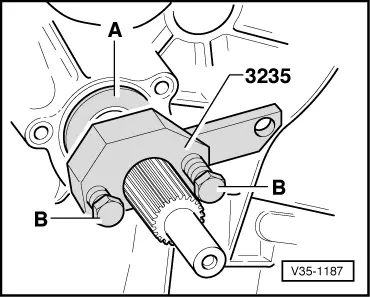

◆ Pressing-in tool 3235

-

◆ Drip tray V.A.G 1306

-

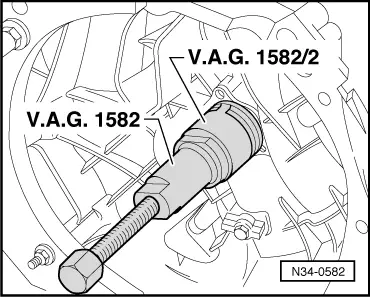

◆ Taper roller bearing extractor V.A.G 1582

-

◆ Clamping piece V.A.G 1582/2

-

◆ Sealant AMV 188 001 02

Removing

-

‒ Place drip tray V.A.G 1306 underneath the gearbox.

-

‒ Drain gear oil.

-

‒ Secure gearbox to repair stand .

|