A4 Mk1

|

Adjusting drive pinion and crown wheel

Adjusting crown wheel

(Adjusting differential) Repairs after which the crown wheel must be adjusted => adjustment overview on Page 39-168. Notes:

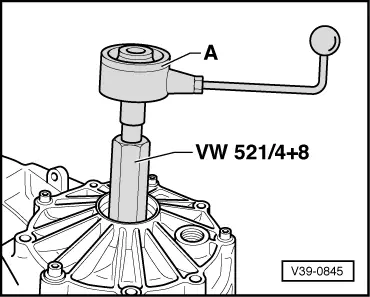

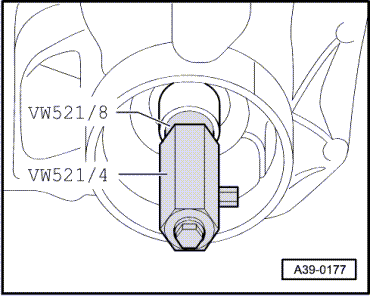

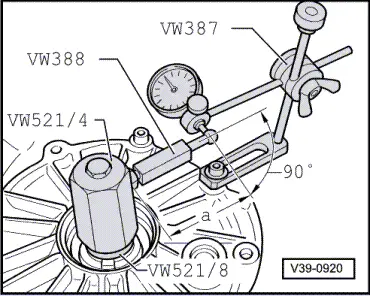

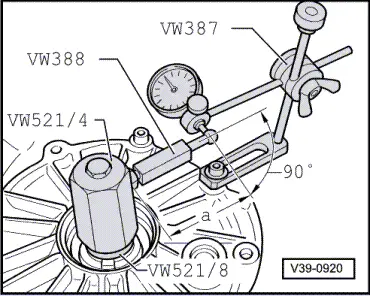

Determining total shim thickness "Stotal" for shims "S1" + "S2" (Setting preload of taper roller bearing for differential)

Note: For measurement purposes a shim "S2" with a thickness of 0.04 in is initially inserted. It is referred to as "S2*" in the following. After determining the backlash "S2*" will be replaced by the correct "S2".

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

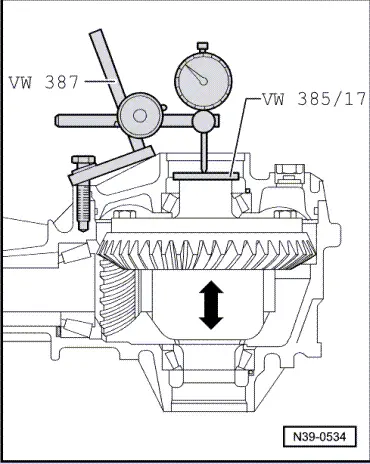

Note: If the measurement has to be repeated, the differential must again first be turned 5 turns in each direction to settle the taper roller bearing.

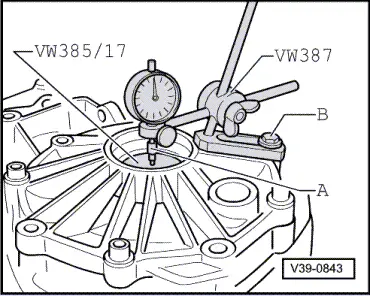

Determining thickness of shim "S1*" Notes:

| |||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: If the individual measurements differ by more than 0.06 mm from each other, the installation of the crown wheel or the final drive set itself is not correct. Check installation; replace final drive set, if necessary. Determining average backlash

Determining thickness of shim "S2"

=> Parts List The following shims are available for "S2"

1) Using the shim tolerance variations it is possible to find the exact shim thickness required, insert two shims if necessary. Determining thickness of shim "S1"

=> Parts List The following shims are available for "S1"

1) Using the shim tolerance variations it is possible to find the exact shim thickness required, insert two shims if necessary. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

→ Check measurement

Notes:

|