Dismantling and assembling cylinder block, crankshaft and flywheel – Pistons and rings

|

Dismantling and assembling cylinder block, crankshaft and flywheel

Pistons and piston rings

|

|

|

|

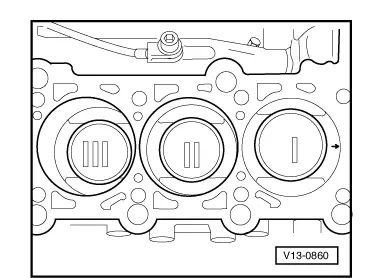

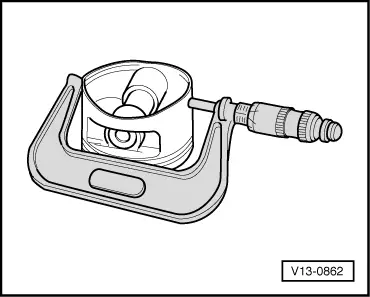

Checking piston diameter

|

|

|||||

|

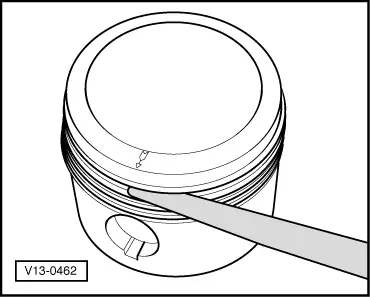

→ Ring-to-groove clearance

|

|

|||||||||||||

|

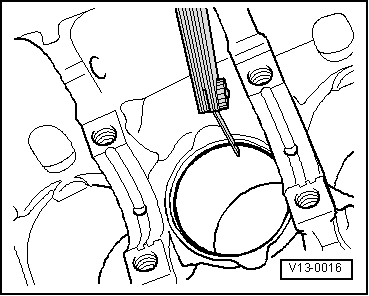

→ Checking piston ring gap

|