A4 Mk1

|

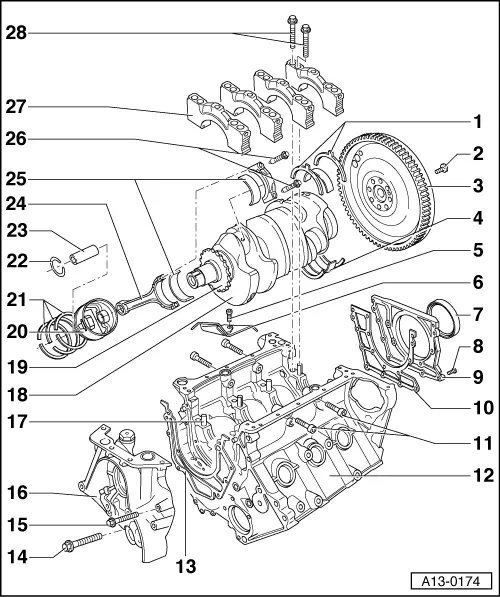

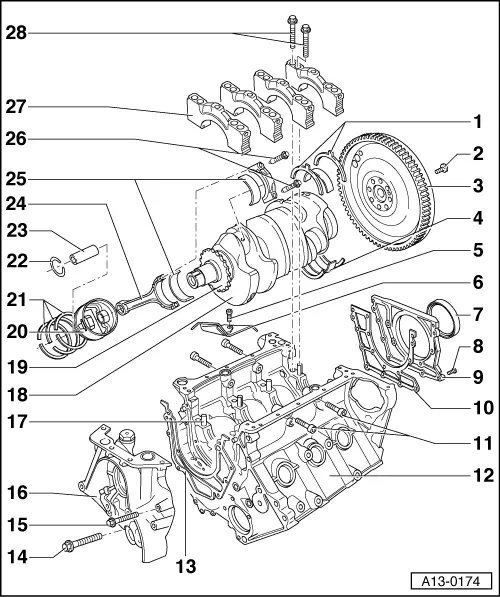

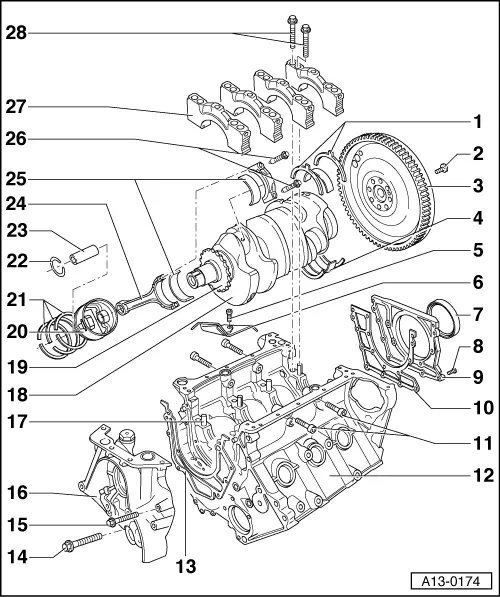

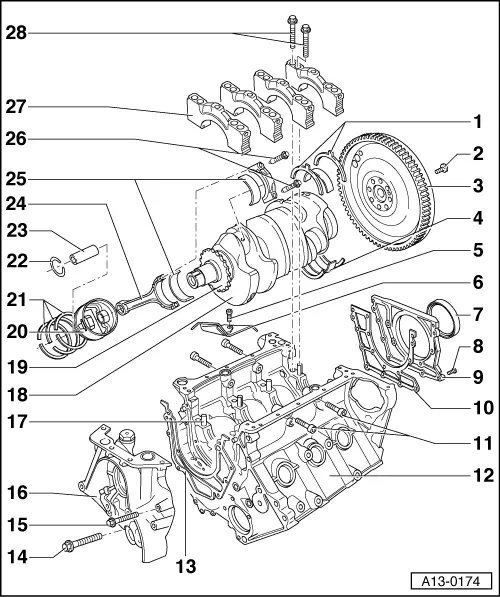

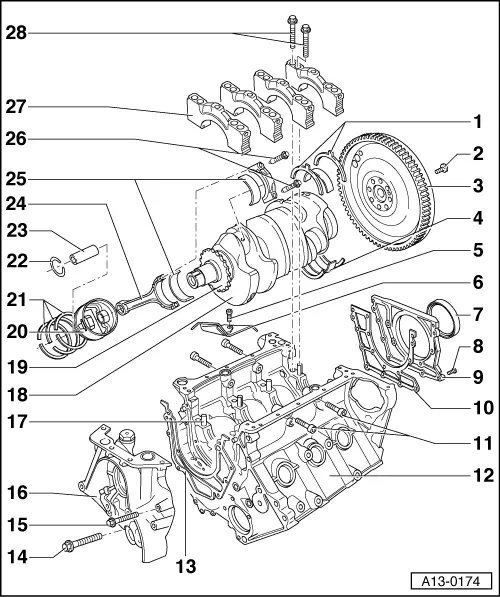

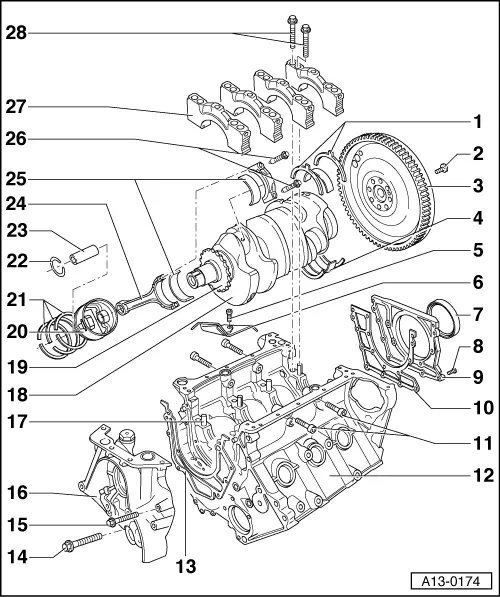

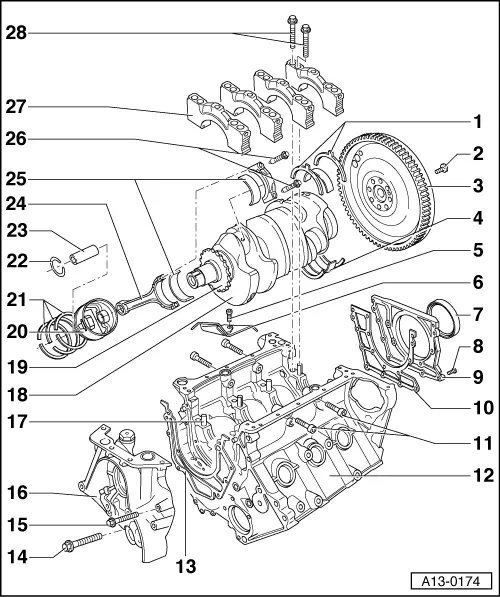

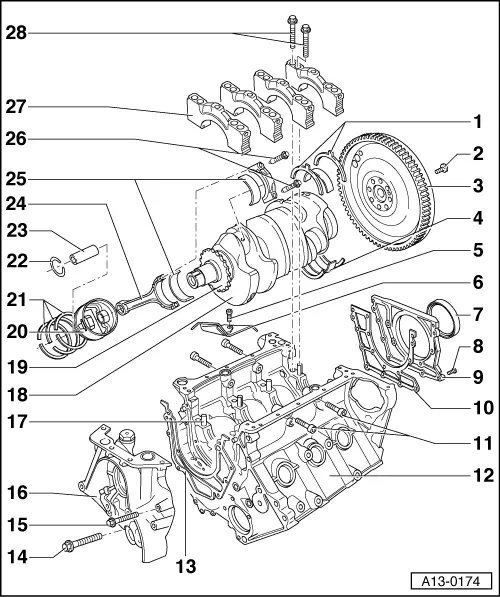

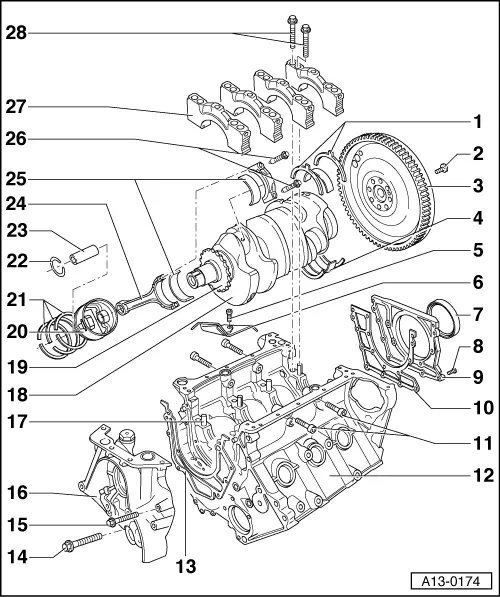

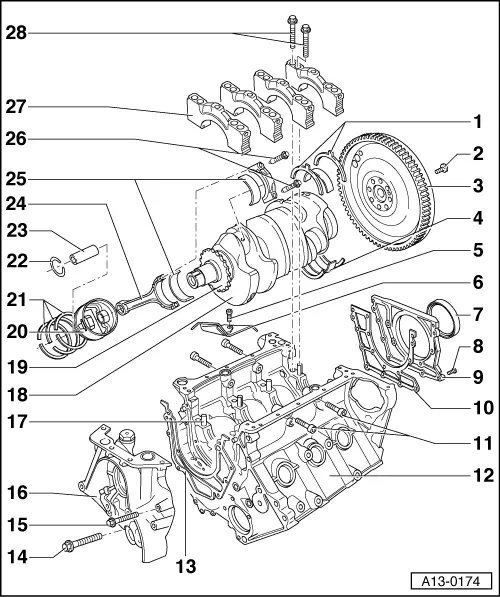

Dismantling and assembling cylinder block, crankshaft and flywheel

Dismantling and assembling cylinder block, crankshaft and flywheel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dismantling and assembling cylinder block, crankshaft and flywheel

Dismantling and assembling cylinder block, crankshaft and flywheel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|