A4 Mk1

|

Servicing Motronic injection system

Testing injection quantity, leak-tightness and spray pattern of injectors

|

|

|

|

Test conditions

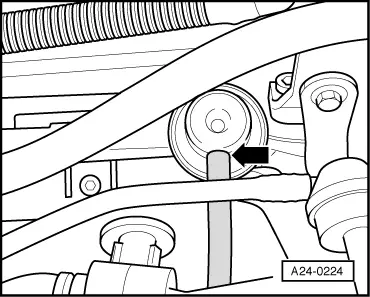

Testing injectors for leaks

|

|

|

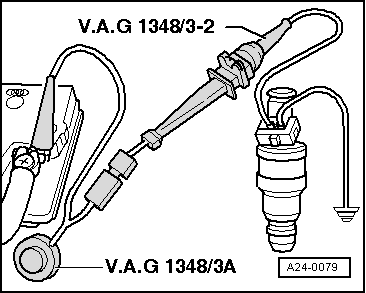

Note: Once the ignition has been switched on the fuel pump runs continuously, even if the engine is not running. This is because when the ignition is switched on the fuel pump relay receives a positive voltage supply via the central electrics. The negative voltage supply for the fuel pump relay comes via the cable bridge on the test box.

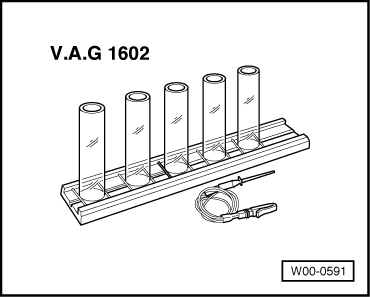

Checking injection quantity

|

|

|

If none of the injectors delivers the specified quantity:

If only one injector fails to deliver the specified quantity:

Note: When checking the injection quantity, also check the spray pattern. The spray pattern should be the same for all the injectors. Installation of the fuel rail together with injectors is performed in the reverse sequence. The following points should be noted when installing:

|