A4 Mk1

|

Wheel bearing housing

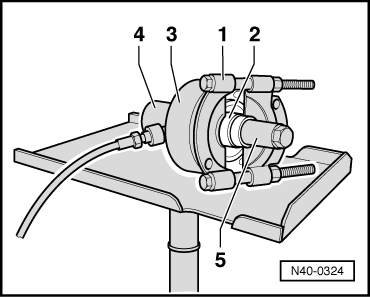

Servicing wheel bearing housing with V.A.G 1459 B

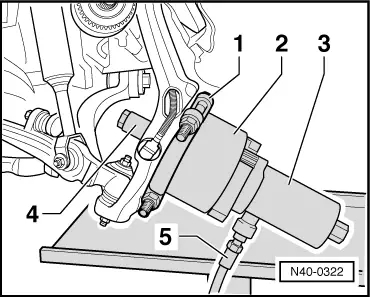

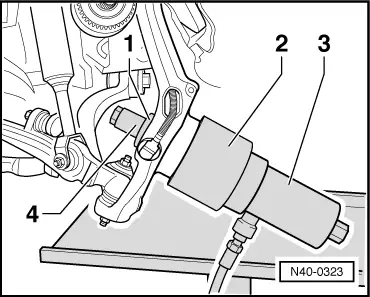

Instead of workshop press V.A.G 1290 A, use can also be made of hydraulic removal and installation tool for wheel bearing and wheel hub V.A.G 1459 B with accessory V.A.G 1459 B /2. Advantages:

Special tools and workshop equipment required

If hand pump V.A.G 1389/1 is already available in workshop, this can be converted to a foot-operated pump. Make use of conversion kit V.A.G 1389/3 for this purpose.

Removing

|

|

|

|

|

|

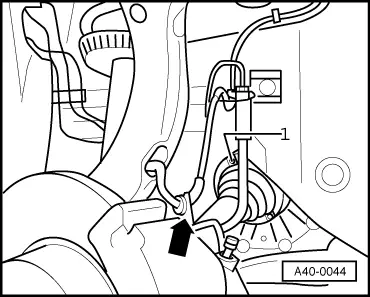

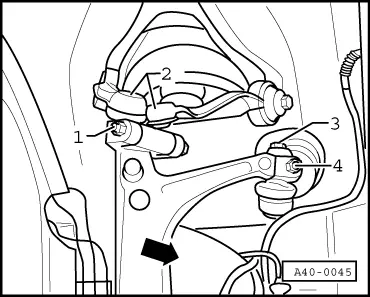

Slots in wheel bearing housing are never to be widened using a chisel or the like. If hexagon bolt cannot be removed from wheel bearing housing, bolt and links -2- must be pressed out of wheel bearing housing .

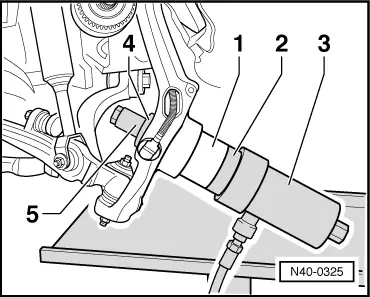

Note: Place gearbox lifter V.A.G 1383/A in position (danger of accident caused by falling components on removing wheel hub and wheel bearing). Removing wheel hub |

|

|

Installation position: Flat surfaces of edges point towards wheel hub

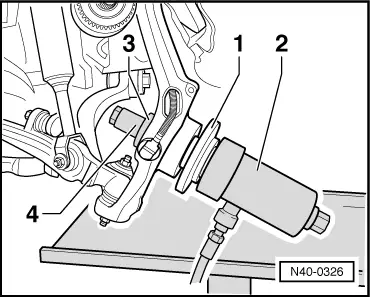

Removing wheel bearing |

|

|

Detaching bearing inner race from hub |

|

|

Installation position: Bevel of edges facing bearing inner race

Pressing in wheel bearing Installation position: Large ID of wheel bearing facing outwards |

|

|

Pressing in wheel hub |

|

|

Perform remaining installation operations in reverse order of removal. |