A4 Mk1

|

|||||||||||||||||||||||||||||

|

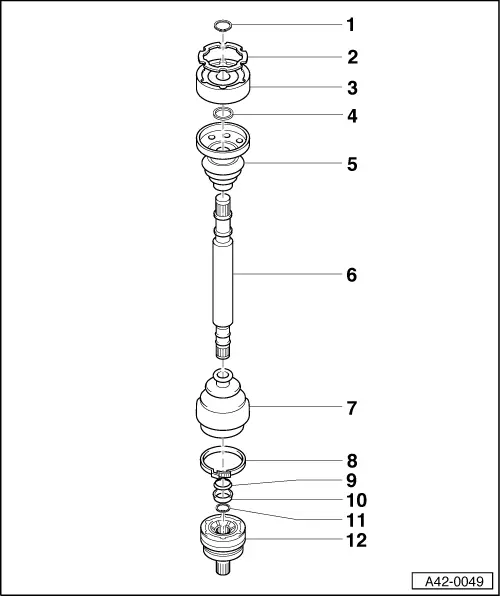

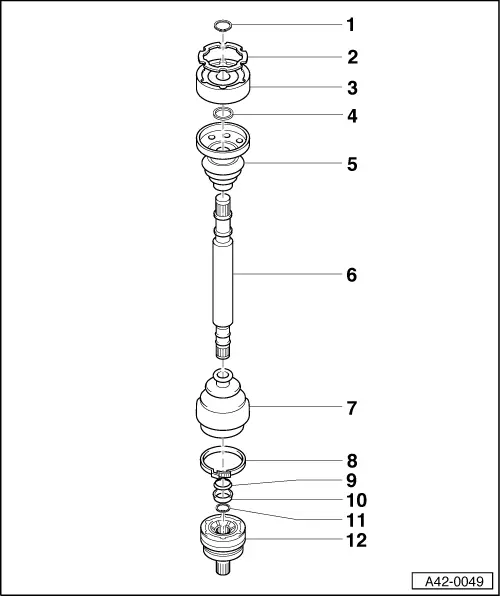

Quantities and type of grease Constant velocity joints are filled with high-temperature grease. => Parts List

Re-grease joint if necessary on replacing boot.

| |||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

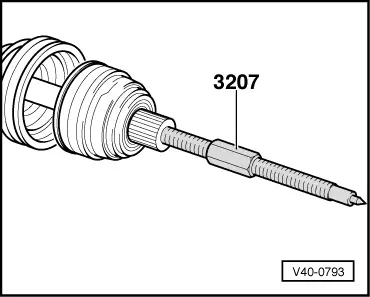

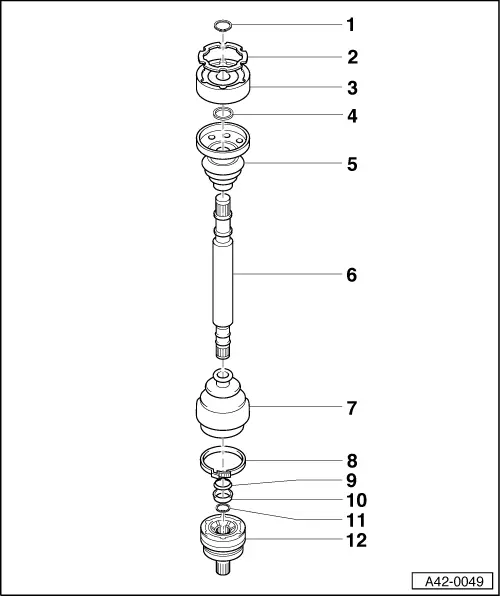

→ Fig.1 Tensioning hose clamp or clamp |

|

|

|

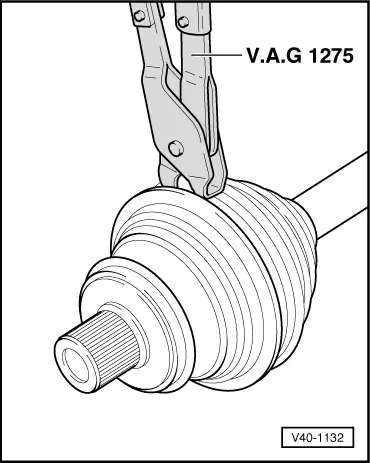

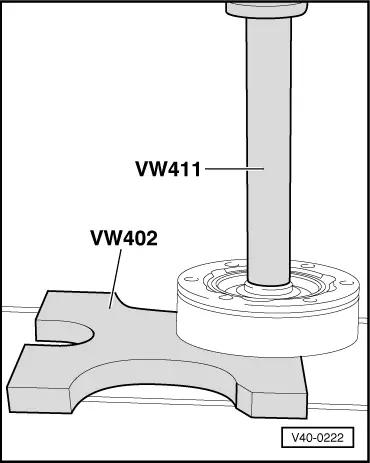

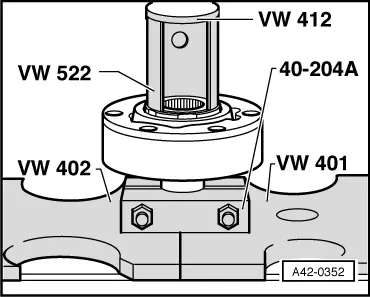

→ Fig.2 Pressing off inner constant velocity joint Notes:

|

|

|

|

→ Fig.3 Pressing on inner constant velocity joint Note: Chamfer at ID of ball hub (splines) must face contact collar of drive shaft.

|

|

|

|

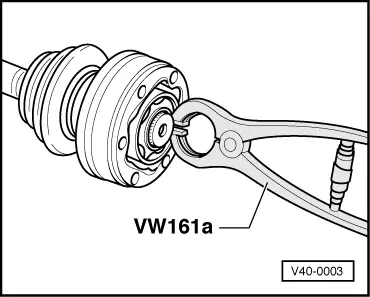

→ Fig.4 Removing/fitting circlip |

|

|

|

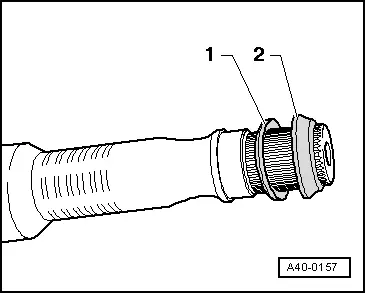

Fig.5 → Installation position of spacer ring and dished washer (wheel end)

|

|

|

|

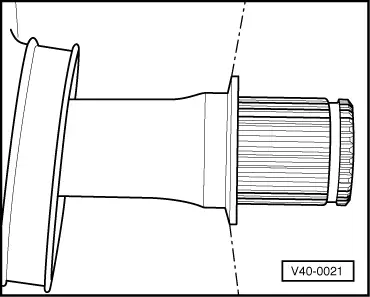

→ Fig.6 Fitting dished washer in correct position |