| –

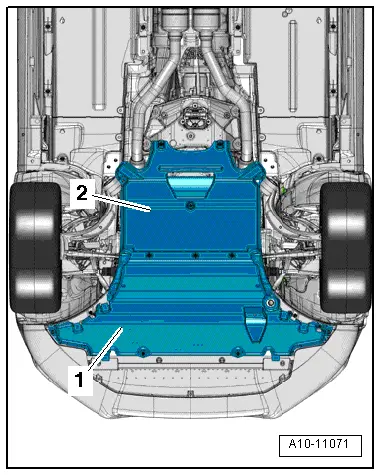

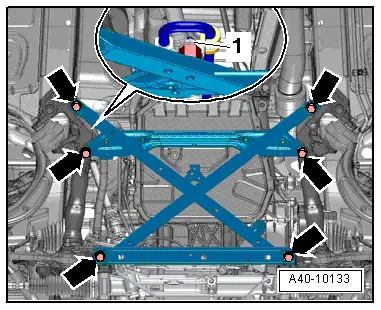

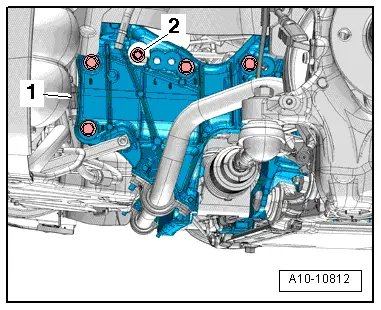

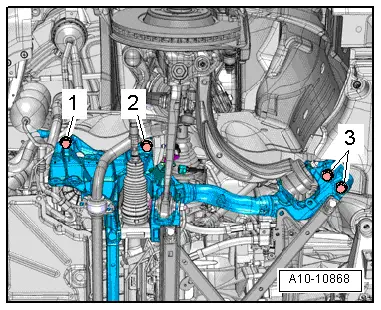

| Mark installation position of subframe on longitudinal members with felt-tip pen. |

| –

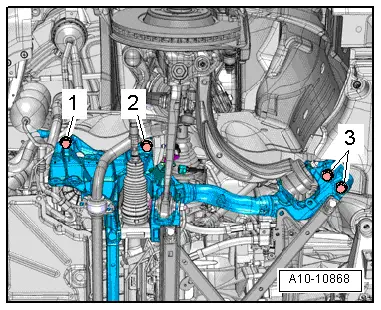

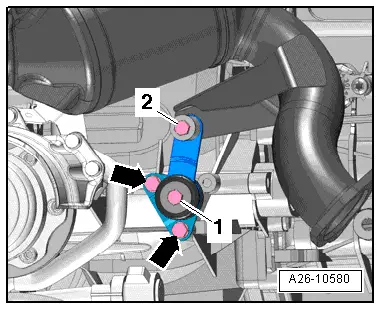

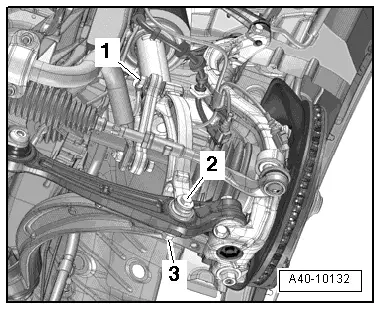

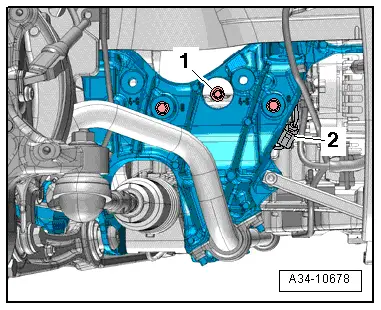

| Unscrew subframe bolts -1, 2 and 3- on both sides in stages and in diagonal sequence. |

Caution | Risk of damage to parts of the running gear. |

| Do not let the vehicle down on the wheels if the gearbox mounting, steering box and subframe cross brace are not properly installed. |

|

| –

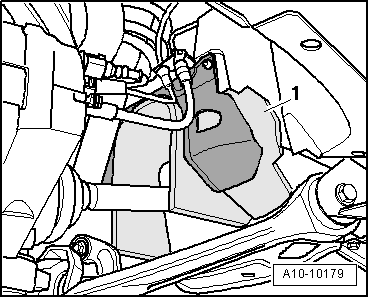

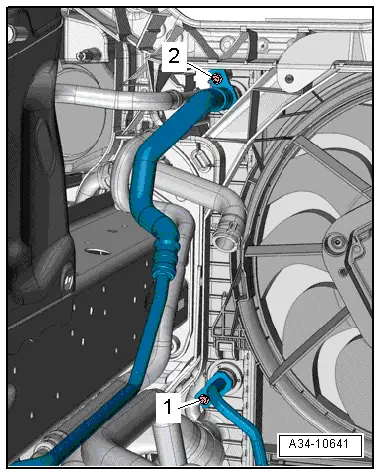

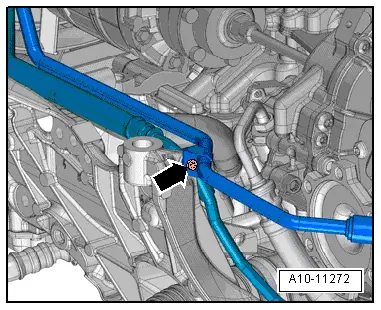

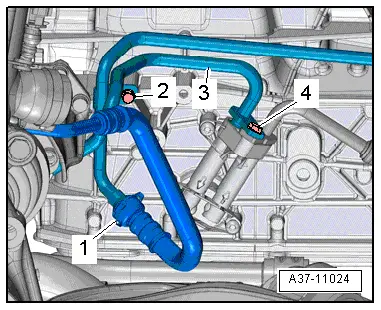

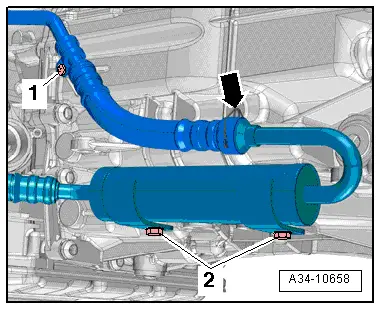

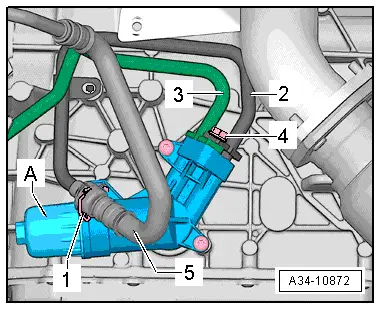

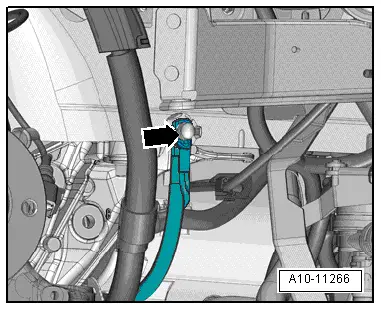

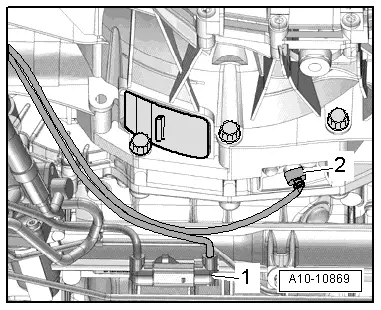

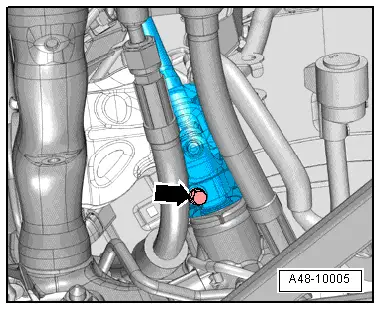

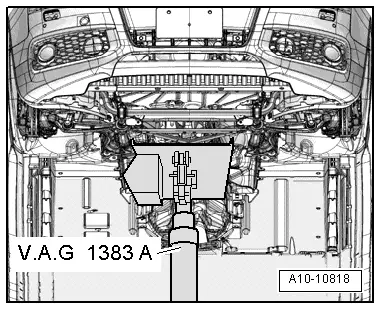

| Using engine and gearbox jack -V.A.G 1383 A-, lower subframe only far enough to remove bottom ATF line; ensure sufficient clearance for hydraulic hoses (left-side) and electrical wiring (right-side). |

| Installation is carried out in reverse sequence; note the following: |

Note

Caution | Risk of damage to gearbox |

| t

| All plugs from engine bung set -VAS 6122- which were inserted in ATF lines and gearbox when dismantling must be removed. |

| t

| If you forget to remove the plugs, the ATF cooling will be ineffective and the gearbox will be damaged. |

|

| –

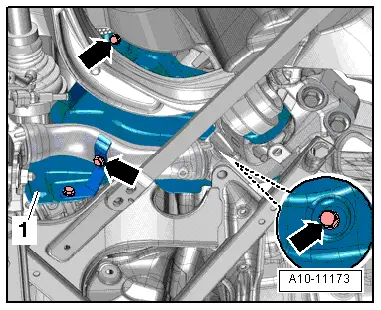

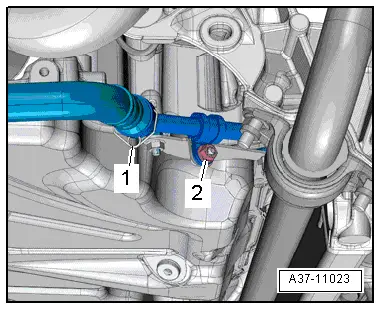

| First press ATF lines onto gearbox and cooler by hand until they engage, then bolt on. |

| –

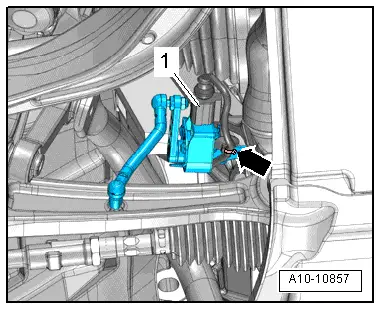

| Press retaining clips onto ATF line connections and then pull to check that clips have engaged properly. |

| –

| Check ATF level and top up as required → Chapter. |

| –

| Align subframe on longitudinal members according to markings made before removal. |

WARNING | Risk of accident if bolted connections are not tightened. |

| The vehicle must not be driven if the subframe mountings have not been fully tightened to the final setting. |

|

| Vehicles with hydraulic power-assisted steering: |

| Continued for all vehicles: |

WARNING | Risk of accident if bolted connections are not tightened. |

| After completing wheel alignment, tighten bolts securing subframe to final setting. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING