| t

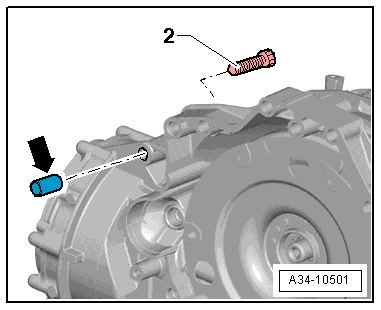

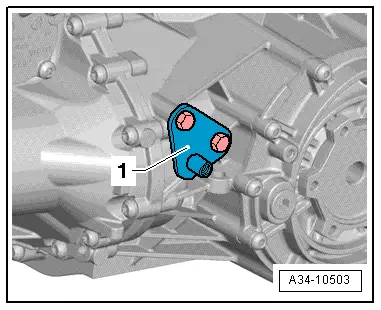

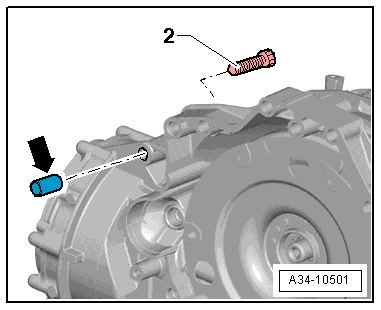

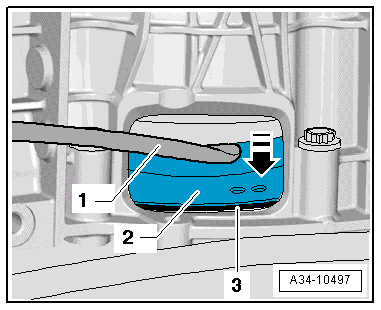

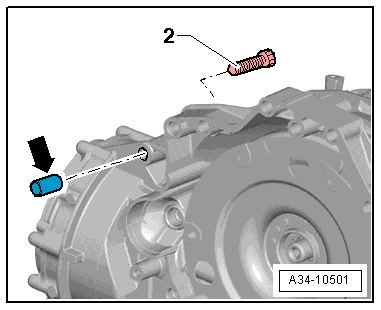

| Bolt -2- also secures the starter to the gearbox and has an additional spacer sleeve -arrow-. |

| t

| The spacer sleeve must be fitted between the starter and the gearbox. |

Caution | Overvoltage can cause irreparable damage to control units. |

| Do not use charger for boost starting. |

|

| –

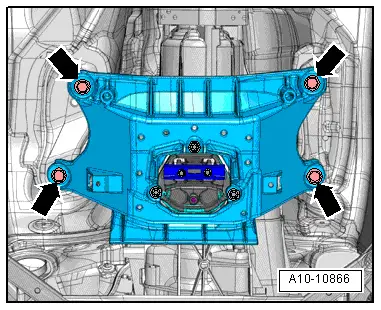

| Check selector lever cable and adjust if necessary → Chapter. |

| –

| Check ATF level and top up as required → Chapter. |

| –

| After performing repair work on gearbox, check gear oil level in front final drive and top up if necessary → Chapter. |

Note | t

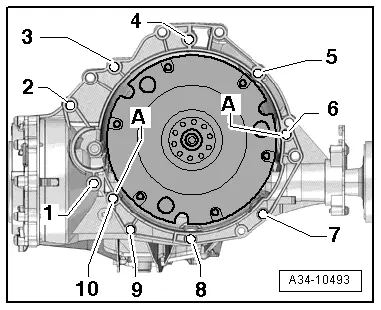

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine or gear oil may be used, but do not use graphite lubricant. |

| t

| Do not use parts which have been degreased. |

| t

| Tolerance for tightening torques is ± 15 %. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution