A4 Mk3

| Exploded view - dismantling and assembling gearbox |

| Removing and installing flange shaft (left-side), clutch module, end cover, side shaft, selector shaft and gearbox cover |

| Exploded view - removing and installing input shaft, output shaft, reverse gear wheel and selector plates / selector forks → Chapter |

| Dismantling and assembling gearbox - assembly sequence → Chapter |

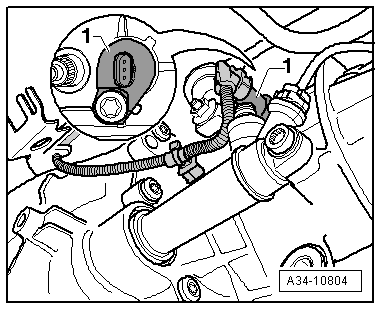

| 1 - | Clutch module |

| q | Removing and installing → Chapter |

| q | Servicing with „Sachs“ version clutch → Chapter |

| q | Servicing with „LuK“ version clutch → Chapter |

| 2 - | Clutch release lever with release bearing and retaining spring |

| q | Removing and installing → Chapter |

| q | Dismantling and assembling → Chapter |

| 3 - | Bolt |

| q | 8 Nm |

| q | 2x |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 4 - | Retaining piece |

| q | Not fitted on all versions |

| q | Installation position: recess for bolts → Item faces towards clutch module |

Note

Note| t | Discontinued as of 02.2008 |

| t | Is also omitted when new guide sleeve is installed → Item |

| 5 - | Guide sleeve |

| q | Remove any existing grease from guide sleeve |

| 6 - | Input shaft oil seal |

| q | Removing and installing → Chapter |

| 7 - | Circlip |

| q | Determining thickness → Fig. |

| q | Insert in circumferential groove in input shaft |

| 8 - | Gearbox housing |

| q | Removing and installing input shaft and output shaft with selector plates / selector forks → Chapter |

| q | Servicing → Chapter |

| q | Removing and installing differential → Chapter |

| 9 - | Oil drain plug |

| q | 45 Nm |

| 10 - | Bolt |

| q | 200 Nm |

| q | For output shaft |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 11 - | Sealing cap |

| q | With oil guide |

| q | For output shaft |

| q | Always renew |

| 12 - | Bolt |

| q | 10 Nm and then turn 45° further |

| q | Aluminium bolts (M8; 22 mm long) |

| q | 4x |

| q | Always renew |

| 13 - | Selector shaft with selector mechanism cover |

| q | Different versions are installed (with and without gearbox neutral position sender -G701- |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| 14 - | O-ring |

| q | Always renew |

| 15 - | Bolt |

| q | 20 Nm and then turn 30° further |

| q | Steel bolts (M8; 30 mm long) |

| q | 3x |

| q | Secures bearing mounting to gearbox cover |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 16 - | Gear detector switch -F208- |

| q | 20 Nm |

| 17 - | Side shaft |

| q | With spur gear |

| 18 - | Bolt |

| q | 150 Nm and then turn 90° further |

| q | Secures side shaft to pinion shaft |

| q | Always renew |

| q | Bolt head: twelve-point, 21 mm across flats |

| 19 - | Bolt |

| q | 15 Nm and then turn 90° further |

| q | Steel bolts (M8; 55 mm long) |

| q | 2x |

| q | Always renew |

| 20 - | Centre hex stud |

| q | 15 Nm and then turn 90° further |

| q | Steel studs (M8/M8; 38 mm long) |

| q | 2x |

| q | Not fitted on all gearboxes, in which case bolts are installed → Item |

| q | Always renew |

| 21 - | Bolt |

| q | 10 Nm and then turn 90° further |

| q | Aluminium bolts (M8; 35 mm long) |

| q | 9 or 11x |

| q | Always renew |

| 22 - | End cover |

| q | Servicing → Chapter |

| 23 - | Circlip |

| q | Determining thickness → Anchor |

| q | Fit in annular groove on output shaft |

| 24 - | Spur gear |

| q | Drive gear for side shaft / pinion shaft (spur gearing) |

| 25 - | Gearbox cover |

| q | Servicing → Chapter |

| 26 - | Bolt |

| q | 15 Nm and then turn 90° further |

| q | Steel bolt (M8; 50 mm long) |

| q | 1x |

| 27 - | Bolt |

| q | 10 Nm and then turn 90° further |

| q | Aluminium bolts (M8; 35 mm long) |

| q | 16x |

| q | Always renew |

| 28 - | Oil filler plug |

| q | 45 Nm |

| 29 - | Bolt |

| q | 10 Nm and then turn 45° further |

| q | Aluminium bolts (M8; 22 mm long) |

| q | Secures gearbox neutral position sender -G701- or sealing plug and sealing cap/selector shaft to gearbox cover |

| q | Not fitted on all versions |

| q | Always renew |

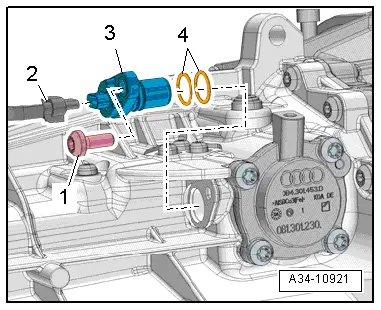

| 30 - | Gearbox neutral position sender -G701- or sealing plug |

| q | Gearbox neutral position sender for vehicles with start/stop system |

| q | Installation position → Fig. |

| q | Not fitted on gearbox with gear detection sensor -G604- → Fig. |

| q | Sealing plug is fitted in place of gearbox neutral position sender -G701- |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

Note

Note| If a sealing plug is fitted in place of the gearbox neutral position sender -G701-, it does not have to be removed when dismantling and assembling the gearbox. |

| q | Can be removed and installed with gearbox installed in vehicle → 6-speed manual gearbox 0B1, front-wheel drive; Rep. gr.34 |

| 31 - | O-ring |

| q | Always renew |

| q | Installed in gearboxes with gearbox neutral position sender -G701- or sealing plug |

| 32 - | Dowel sleeve |

| q | 2x |

| 33 - | Bolt |

| q | 15 Nm and then turn 45° further |

| q | Steel bolts (M8; 25 mm long) |

| q | 3x |

| 34 - | Flange shaft (left-side) |

| q | With mounting bracket |

|

|

|

|