| –

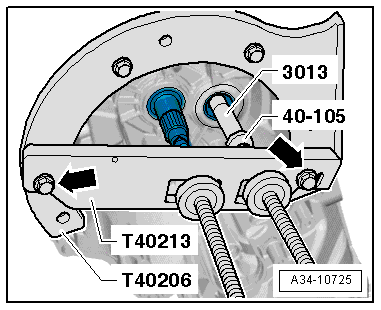

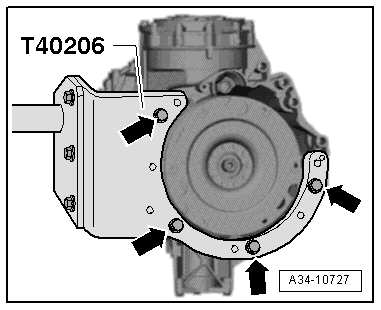

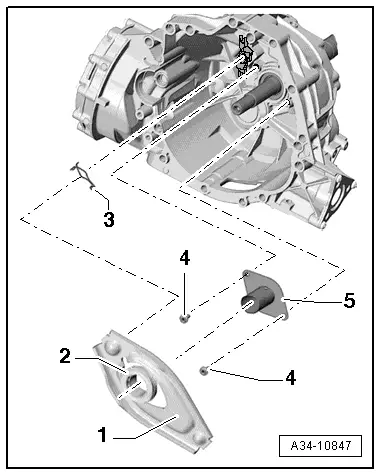

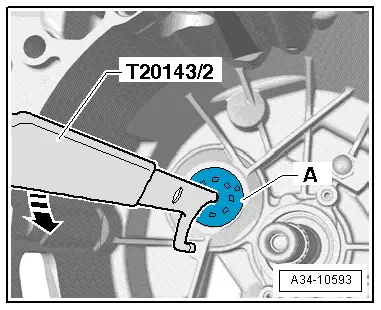

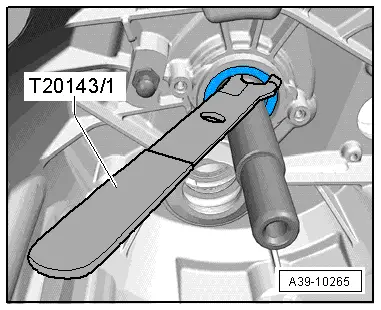

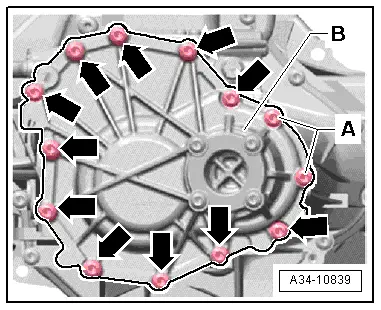

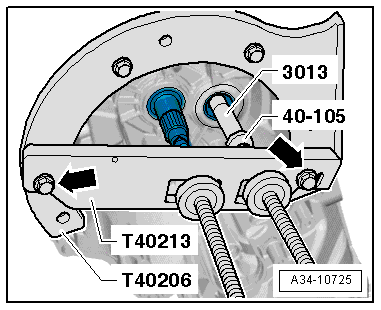

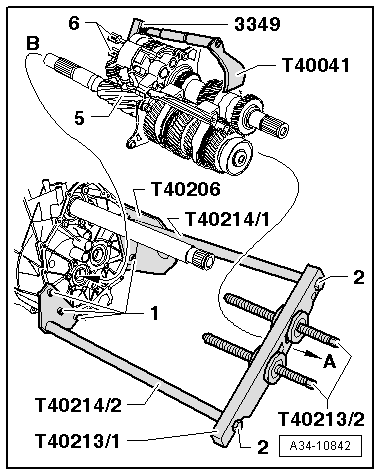

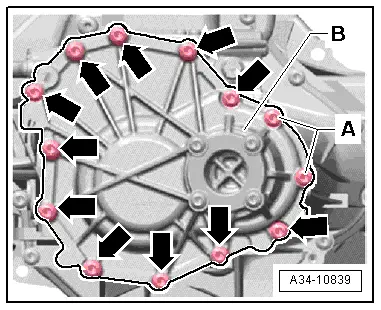

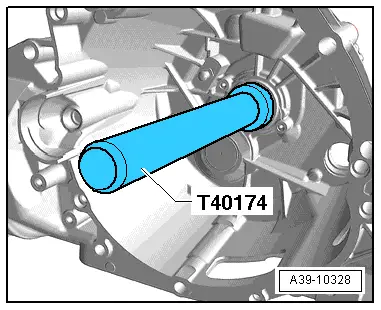

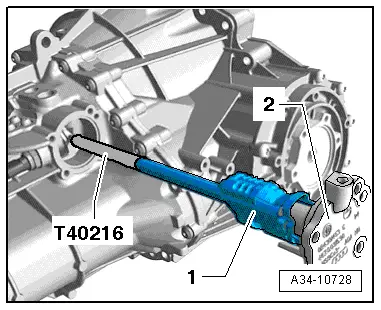

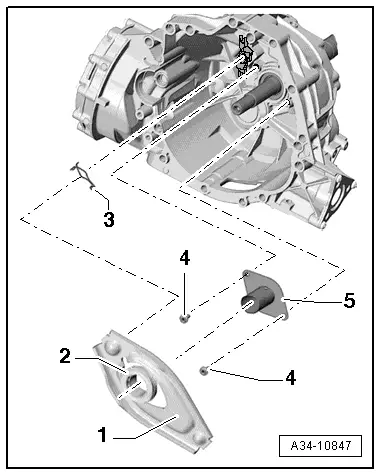

| Attach separating tool -T40213- to gearbox support -T40206- with bolts -arrows-. |

Caution | Risk of damage to gears, shafts and bearings. |

| t

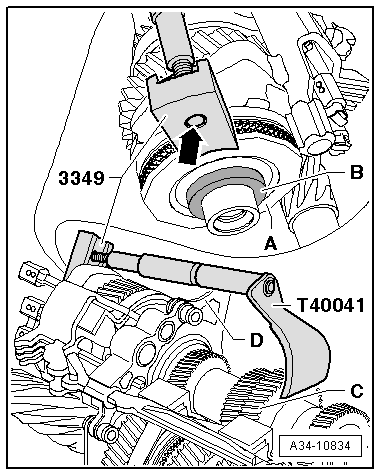

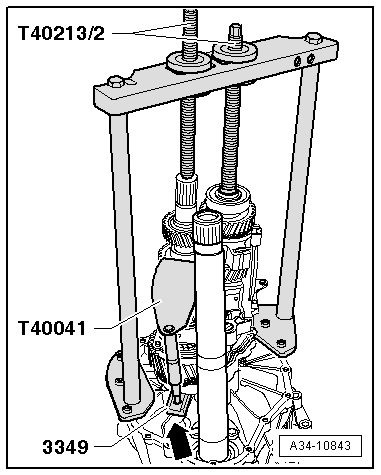

| The input shaft and output shaft must be pressed out together. |

| t

| It is permissible to turn the spindles alternately not more than one turn at a time when pressing out the shafts. |

| t

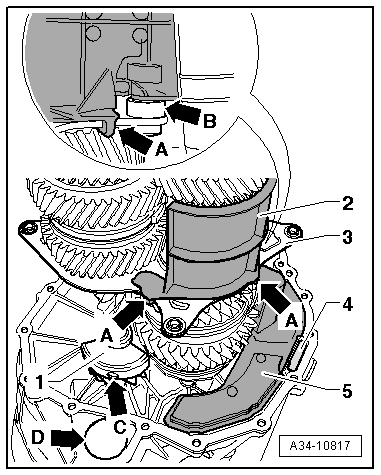

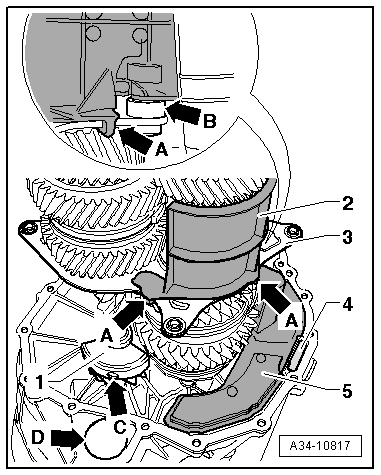

| When taking out the shaft group, pay attention to the reverse gear synchroniser. It must not be allowed to slip off the output shaft. |

|

| –

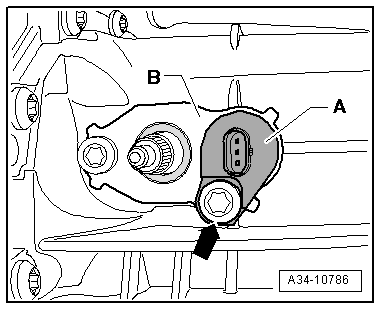

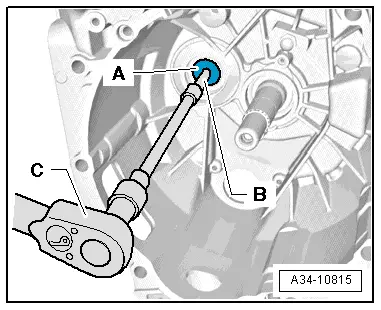

| By turning spindles of separating tool -T40213- alternately one turn at a time, press input shaft and output shaft out of ball bearings in gearbox housing. When doing so, secure the shaft group to stop it dropping down (2nd mechanic). |

| –

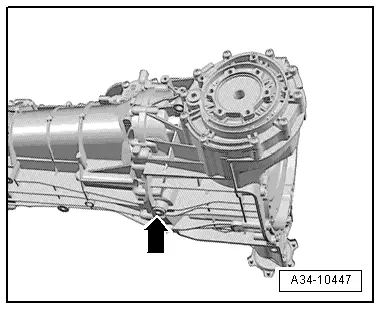

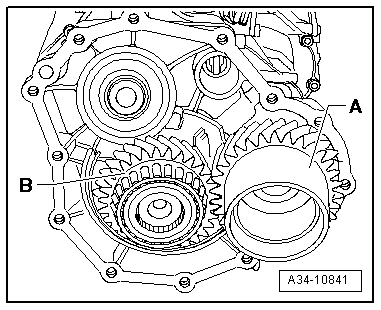

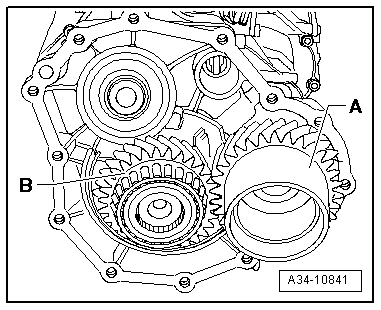

| Detach the input and output shaft together with the selector fork cluster from the gearbox housing. |

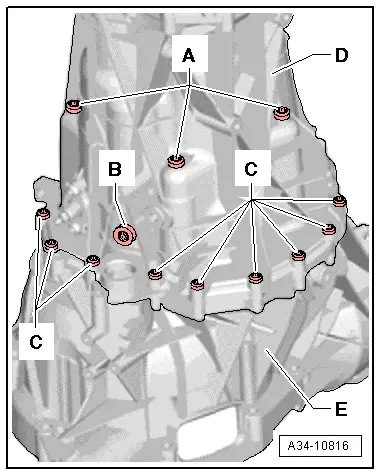

Note | On replacing the gearbox cover, the input gear/spur gear mechanism, the tapered roller bearings for the input gear/spur gear mechanism or the end cover, the first step is to re-determine the shim for the pre-load of the input gear/spur gear mechanism tapered roller bearings → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution