A5

| Renewing valve stem oil seals with cylinder head installed |

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

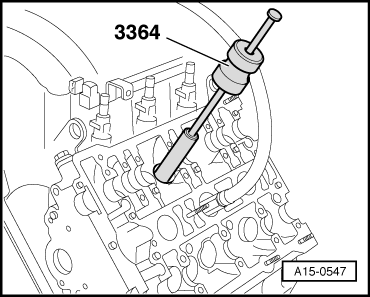

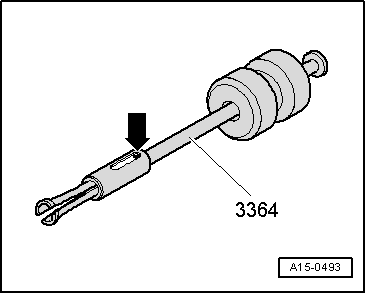

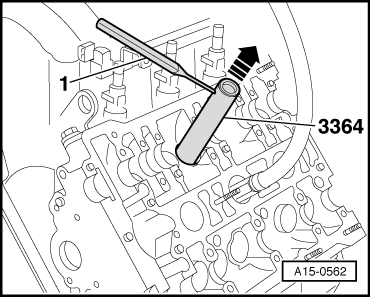

| t | Valve stem seal puller -3364- |

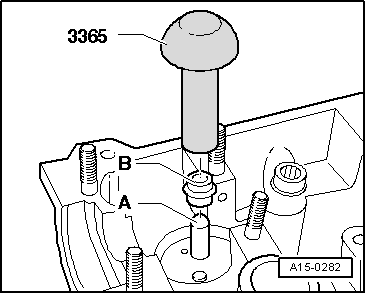

| t | Valve stem seal fitting tool -3365- |

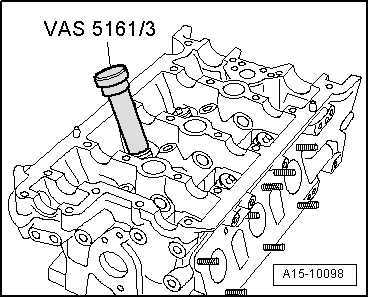

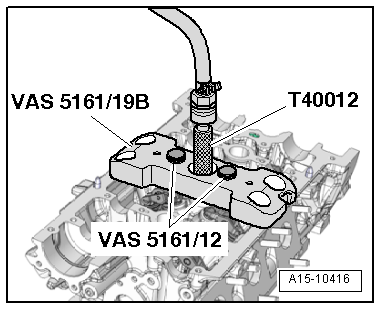

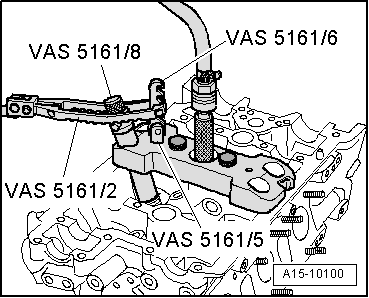

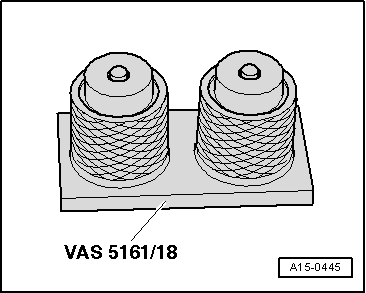

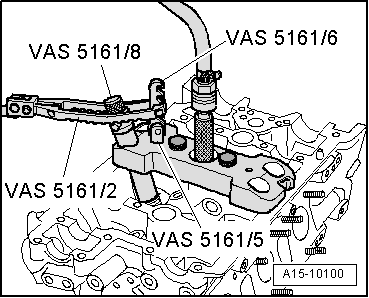

| t | Removal and installation device for valve cotters -VAS 5161- with guide plate -VAS 5161/19B- |

| t | Adapter -T40012- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution