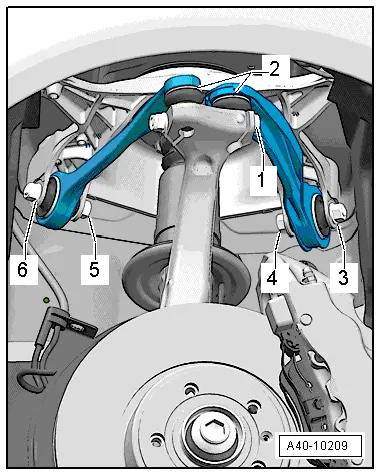

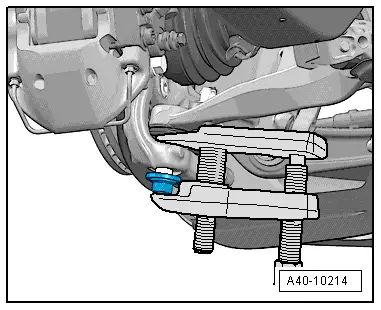

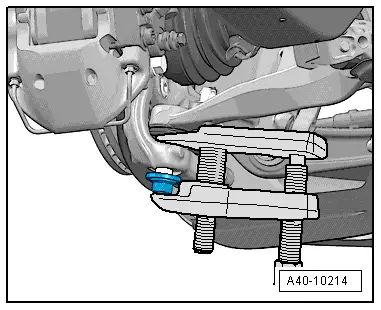

| Press down upper links as far as possible while tightening nut. |

| –

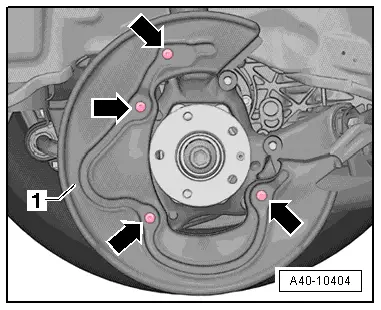

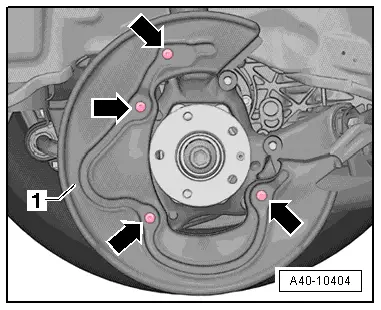

| Tighten bolt connection -1- to specified torque. |

| –

| Tighten bolt securing drive shaft to wheel hub → Chapter. |

| –

| On vehicles with automatic headlight range control, carry out basic adjustment of headlights → Rep. gr.94. |

| –

| If, on vehicles with electronic damping control, the vehicle level sender has been removed and refitted or the linkage detached, the reference position must be re-adapted → Chapter → Vehicle diagnostic tester. |

| –

| If the reference position has been re-adapted on vehicles with lane departure warning, the lane departure warning control unit -J759- must be recalibrated → Chapter. |

| –

| Check and adjust wheel alignment as required, see chart → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note