Freelander Service Procedures

REAR AXLE & FINAL DRIVE

51-6

REPAIRS

Refit

1. Fit new collapsible spacer.

2. Fit pinion bearing and oil thrower.

3. Clean pinion flange and oil seal recess.

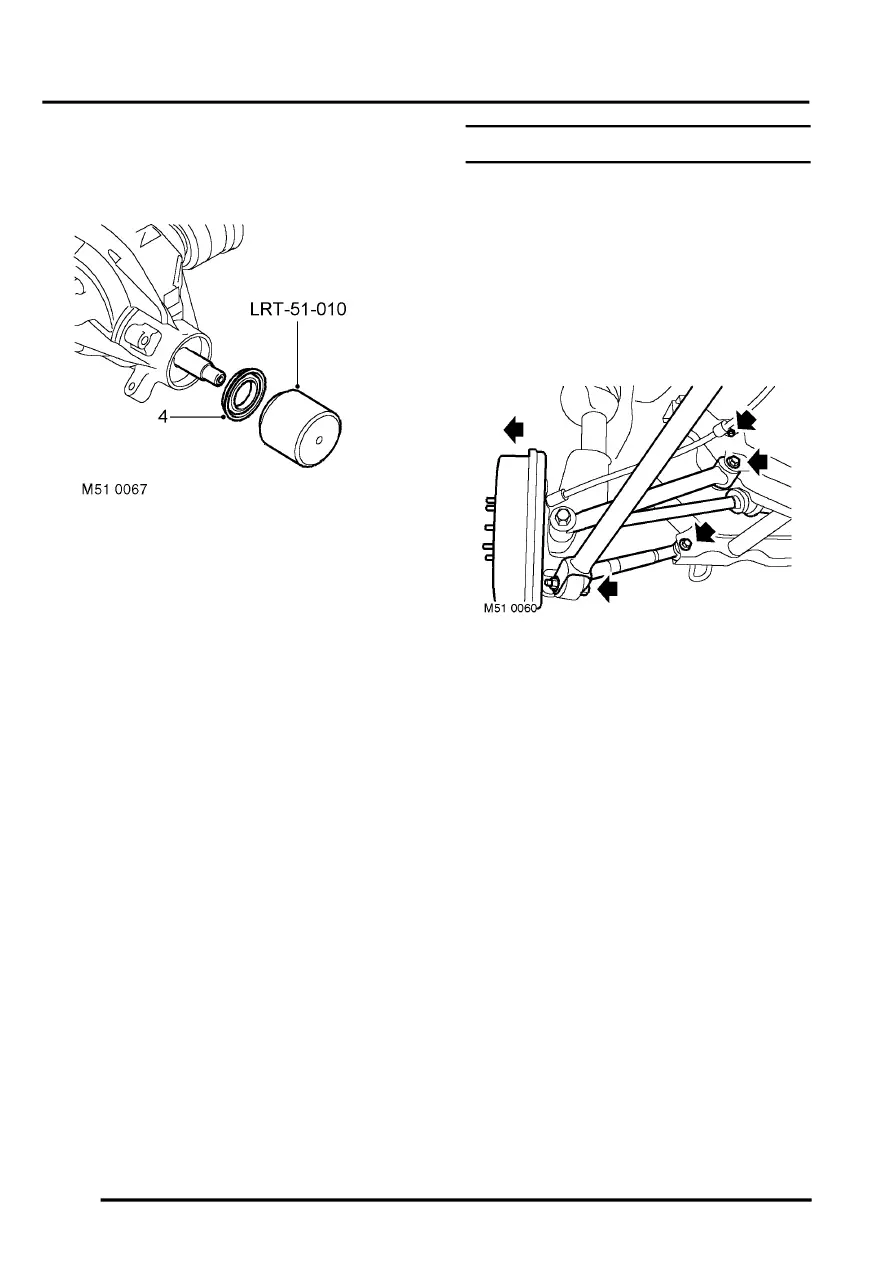

4. Fit new oil seal using LRT-51-010.

5. Fit pinion flange and washer.

6. Restrain pinion flange using LRT- 51-003.

7. Fit new pinion nut and tighten to 190 Nm (140

lbf.ft).

8. Check for end float on pinion. If end float exists

continue to tighten pinion nut until end float is

removed.

9. Continue to tighten pinion nut until correct

preload is obtained.

10. Pinion preload is 1.7 - 2.8 Nm (1.2 - 2.1 lbf.ft), if

higher replace collapsible spacer.

CAUTION: Do not tighten pinion nut to more

than 373 Nm (275 lbf.ft), or the collapsible

spacer will compress too far.

11. Clean propeller shaft flange and mating face.

12. Position propeller shaft to rear axle and align

reference marks.

13. Tighten propeller shaft nuts and bolts to 65 Nm

(48 lbf.ft).

14. Fit drive shafts.

REPAIRS, Oil seal - differential housing.

15. Check differential oil level.

Oil seal - differential housing

$% 51.20.36

Remove

1. Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2. Remove road wheel.

3. Remove bolt securing handbrake cable to

subframe.

4. Remove nut and bolt securing trailing link to

rear hub, collect spacer from under bolt head.

5. Remove nut and bolt securing fixed transverse

link to subframe. Collect dynamic damper.

6. Remove nut and bolt securing adjustable

transverse link to subframe.

7. Position drain tin to catch oil spillage.

8. With assistance pull hub assembly outwards.