| –

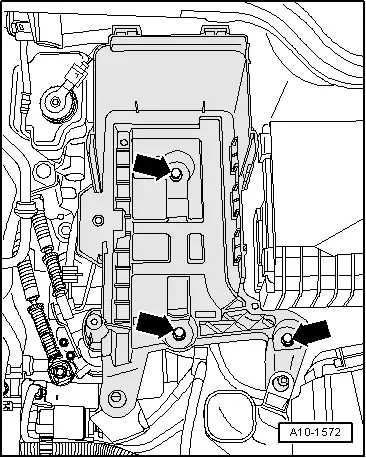

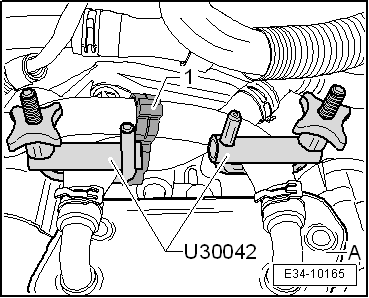

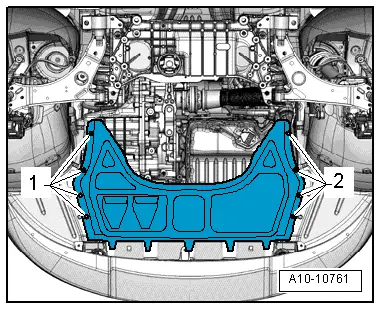

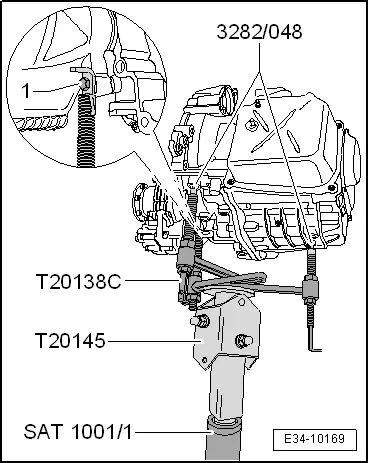

| Attach the engine and gearbox jack -SAT 1040- and connect the base -T20145- under the vehicle using the hydraulic engine and gearbox jack adapter -SAT 1001/1-. |

| –

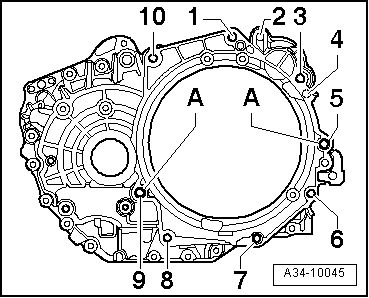

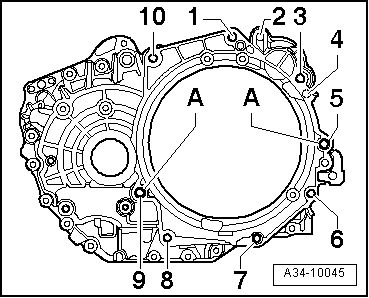

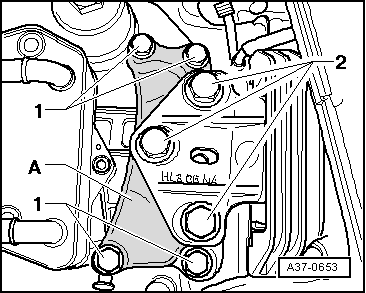

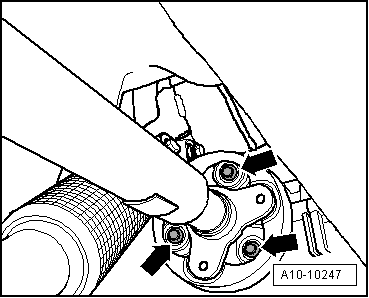

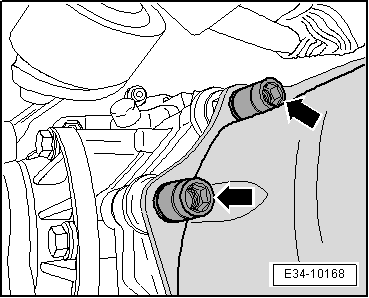

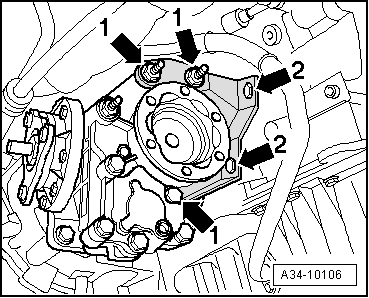

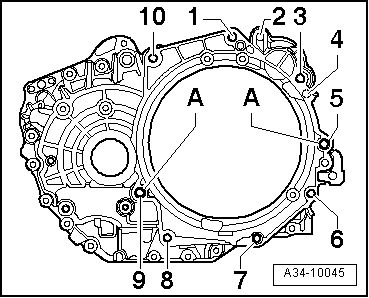

| Unscrew the remaining connecting bolts of the gearbox motor -6, 7, 8 and 9-. |

| –

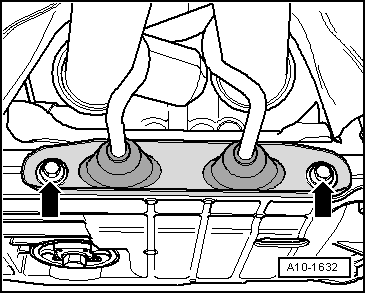

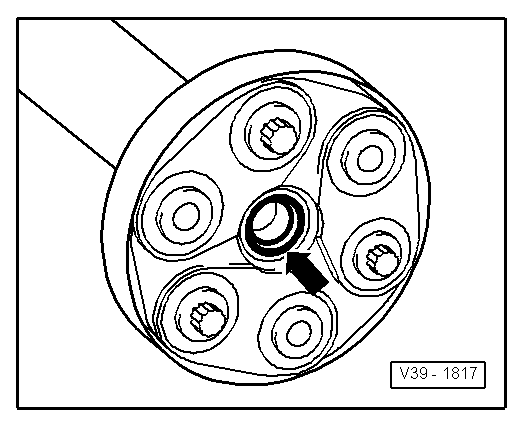

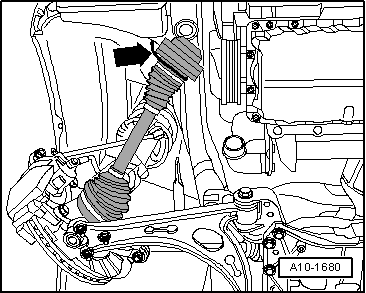

| Remove the gearbox from the dowel sleeves -A-. |

| –

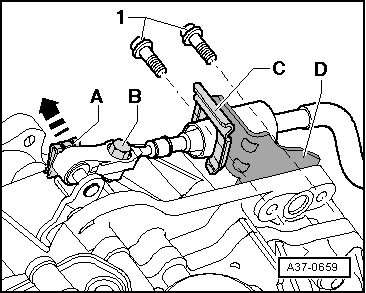

| Pull the gearbox off engine first from the bevel box side and then from the front side. |

| –

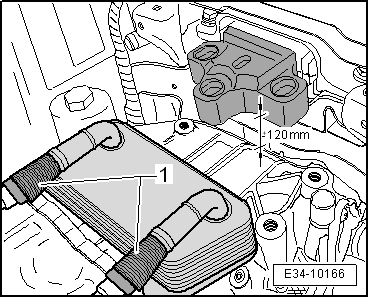

| Using the hydraulic jack -SAT 1040-, carefully lower the gearbox. in doing so, take care that no cables or lines catch anywhere. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution