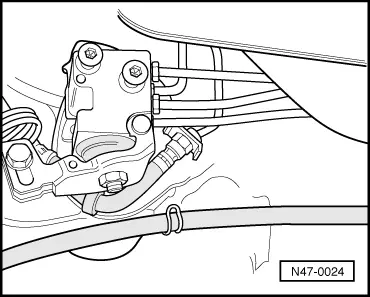

| The brake pressure regulator is mounted on a bracket which is in turn fixed to a rear axle mounting bracket and is controlled from the rear axle by a spring. |

| Firmly depress the brake pedal and release quickly (vehicle standing on its wheels). This must cause the brake pressure regulator lever to move. |

| Checking and adjusting pressure |

Note! | The brake pressure regulator is set with the vehicle unladened → Note. |

| –

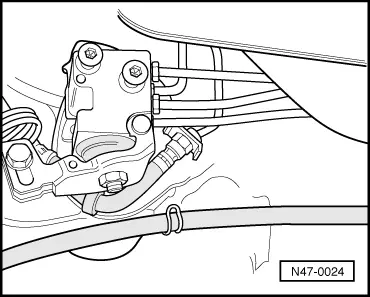

| Lift vehicle and connect the pressure gauges to front left brake caliper and to the rear right wheel cylinder. |

| 1)

| The term “unladen” means: The weight of the vehicle ready for the road (full fuel tank, spare wheel, tool kit and jack). |

| –

| Lower vehicle and bounce the rear of the vehicle several times. |

| –

| Depress brake pedal and measure pressures. |

| –

| Compare figures attained with specifications → Chapter and if necessary adjust. |

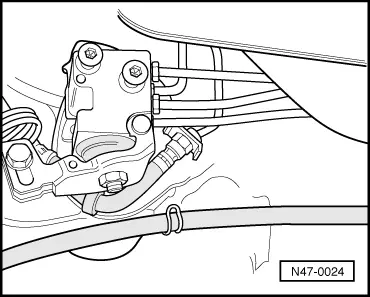

| Rear axle test pressure too high: |

| –

| Release regulator spring. |

| Rear axle test pressures too low: |

| –

| Tension regulator spring. |

Note! | Do not adjust with brake pedal depressed, therefore observe the following sequence: |

| –

| Read off figures and if necessary, readjust. |

| –

| Remove pressure gauges and bleed brake system → Chapter. |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!