Leon Mk2

| Driveshaft from year 2001 models onwards: repairing |

| Special tools and workshop equipment required |

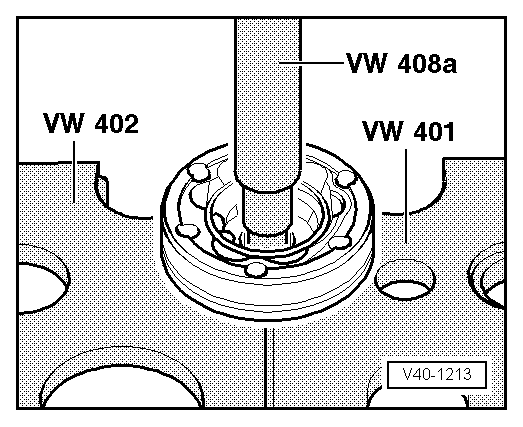

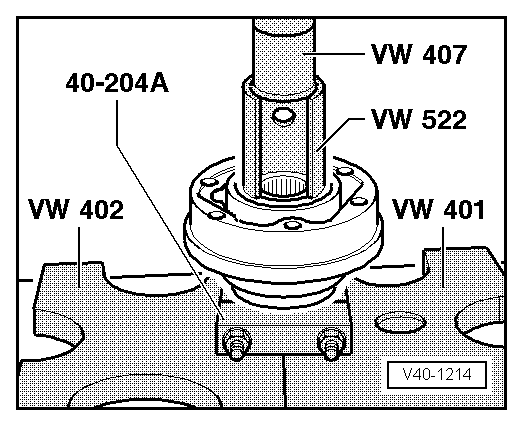

| t | Pressure plate -VW 401- |

| t | Pressure plate -VW 402- |

| t | Terminal crimper -VW 407- |

| t | Terminal crimper -VW 408 A- |

| t | Support sleeves -VW 522- |

| t | Tensor -40-204 A- |

| t | Pliers -V.A.G 1275- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Pliers -V.A.G 1682- |

|

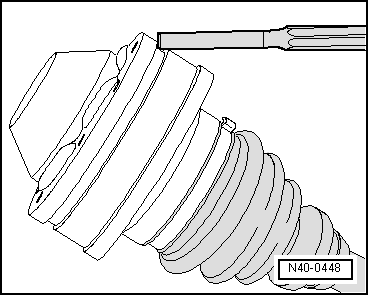

| 1 - | Tightening clip |

| q | Replace |

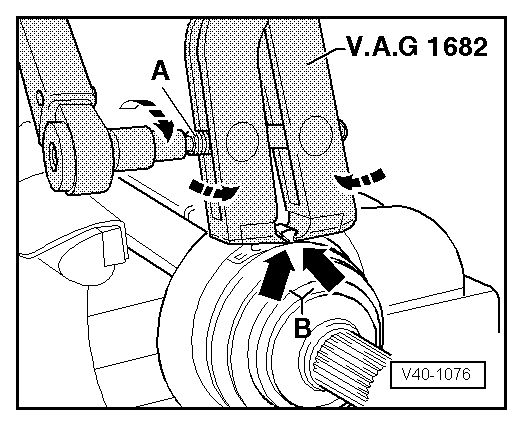

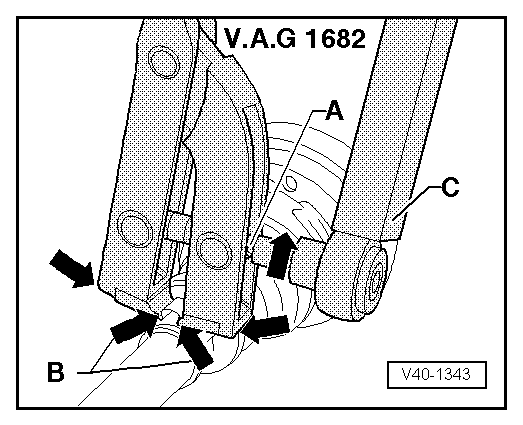

| q | Tighten → Fig. |

| 2 - | Constant velocity exterior joint |

| q | Only replace entirely |

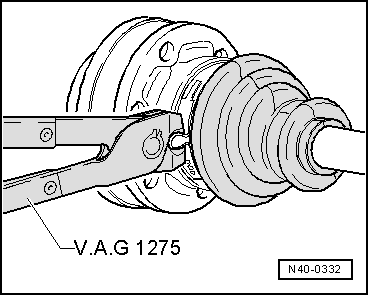

| q | Releasing → Fig. |

| q | Checking → Chapter |

| q | insert into the driveshaft using a plastic hammer, until the compressed circlip is decompressed |

| q | Grease → |

| 3 - | Hexagonal bolt |

| q | 150 Nm, and turn a further 90° |

| q | When tightening and loosening, the vehicle must rest on its wheels |

| q | Replace after each removal |

| 4 - | Driveshaft |

| 5 - | Circlip |

| q | Replace |

| q | Insert in the driveshaft groove |

| 6 - | Tightening clip |

| q | Replace |

| q | Tighten → Fig. |

| 7 - | Dust guard for constant velocity joint |

| q | Material: Hytrel (polyester elastomer) |

| q | Without ventilation opening |

| q | Check for cracks or wear, and replace if necessary |

| 8 - | Circlip |

| q | Replace |

| 9 - | Inner constant velocity joint |

| q | Only replace entirely |

| q | Releasing → Fig. |

| q | Checking → Chapter |

| q | Fitting → Fig. |

| q | The bonding surfaces must be free of grease and oil |

| q | Grease → |

| q | Insert and remove with long nose pliers |

| 10 - | Cover |

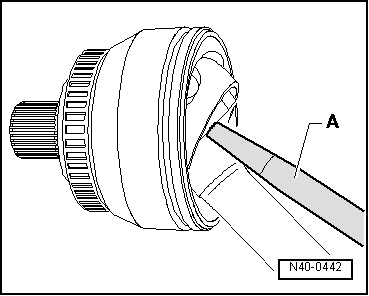

| q | Carefully remove using an awl |

| q | Apply D-3 on the seal surface before connecting it to the constant velocity joint |

| q | The bonding surface must be free of grease and oil! |

| 11 - | Tightening clip |

| q | Replace |

| q | Tighten → Fig. |

| 12 - | Dust guard of the inner constant velocity joint |

| q | With breather hole |

| q | Check for cracks or wear, and replace if necessary |

| q | Clean the driveshaft properly before fitting the new dust guard |

| q | Before fitting the dust guard, grease the driveshaft profile slightly |

| 13 - | Additional plate |

| 14 - | Bolt with internal splined head |

| q | First tighten diagonally to 10 Nm |

| q | Tighten completely to 70 Nm |

| q | Replace after each removal |

| 15 - | Cover |

| q | Carefully remove using an awl → Fig. |

| q | The bonding surface must be free of grease and oil! |

| q | Apply D-3 on the seal surface before connecting it to the constant velocity joint |

| 16 - | Seal |

| q | Replace, remove the protection layer and attach it to the joint. |

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|