Leon Mk2

| Driveshaft: repairing |

| For vehicles with manual gearbox 006 and automatic gearbox 099 |

| Special tools and workshop equipment required |

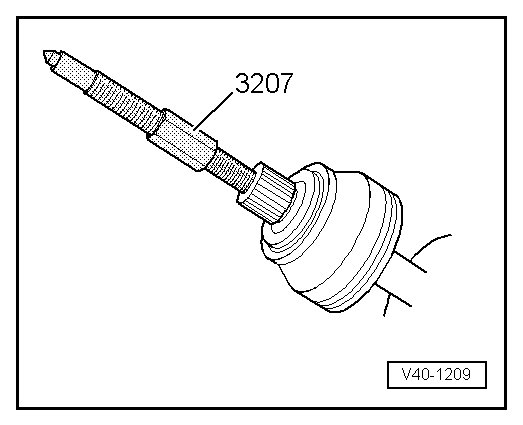

| t | Pressure spindle -3207- |

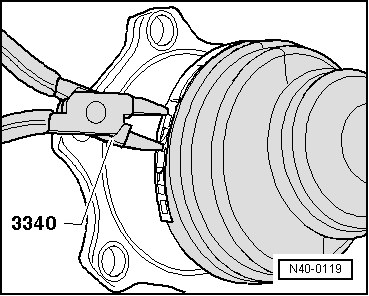

| t | Pliers -3340- |

| t | Pliers -V.A.G 1275- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

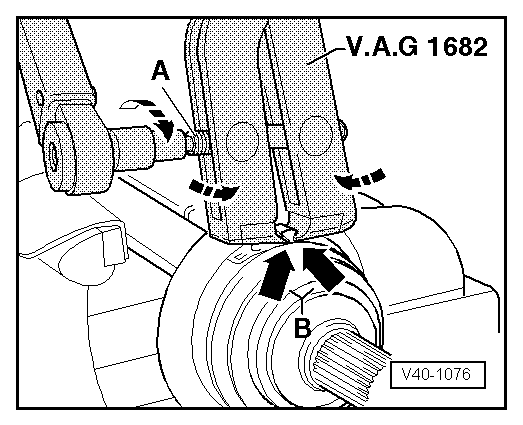

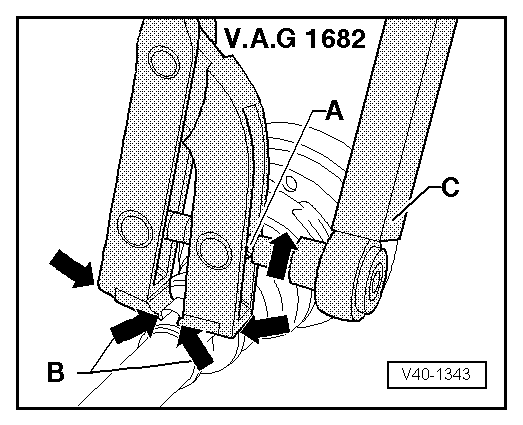

| t | Pincers -V.A.G 1682- |

|

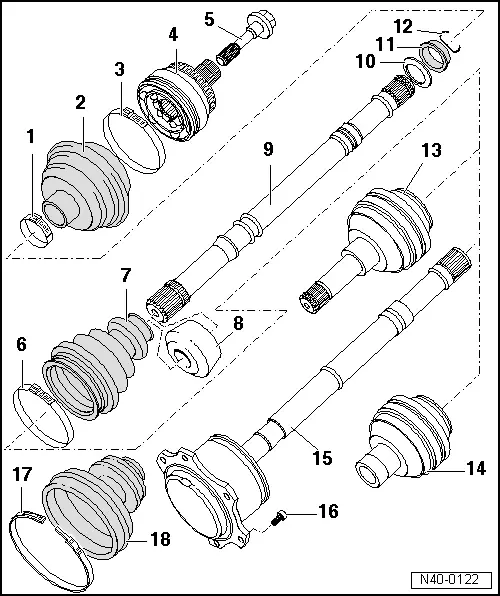

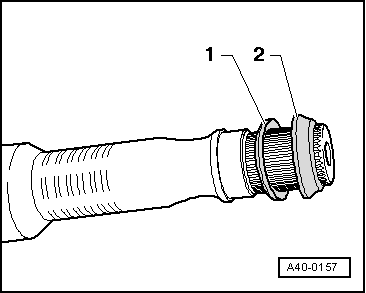

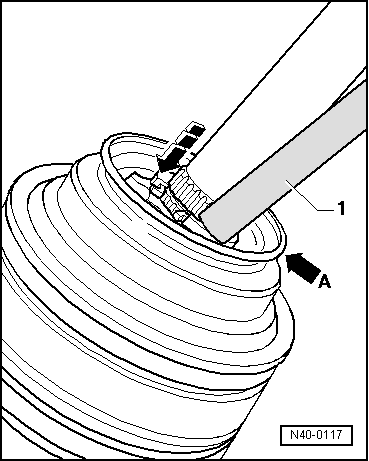

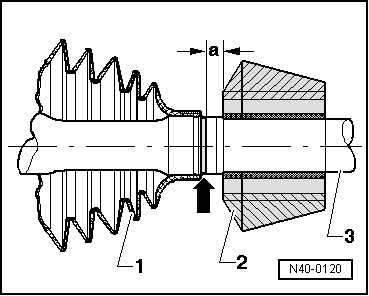

| 1 - | Tightening clip |

| q | Replace |

| q | Tighten → Fig. |

| 2 - | Dust guard for constant velocity joint |

| q | Check for cracks or wear, and replace if necessary |

| 3 - | Tightening clip |

| q | Replace |

| q | Tighten → Fig. |

| 4 - | Constant velocity exterior joint |

| q | Only replace entirely |

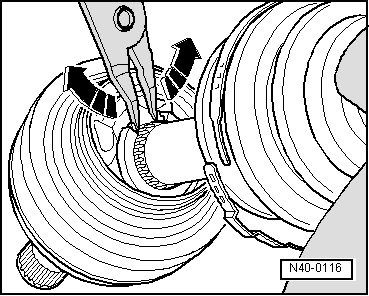

| q | Releasing → Fig. |

| q | insert into the driveshaft using a plastic hammer, until the compressed circlip is decompressed |

| q | Grease → |

| q | Checking → Chapter |

| 5 - | Hexagonal bolt |

| q | 150 Nm, and turn a further 90° |

| q | Replace after each removal |

| 6 - | Tightening clip |

| q | Replace |

| q | Tighten with the -V.A.G 1275- |

| 7 - | Dust guard of the inner constant velocity joint |

| q | Check for cracks or wear, and replace if necessary |

| q | Clean the driveshaft properly before fitting the new dust guard |

| 8 - | Counterweight |

| q | Assembly position → Fig. |

| 9 - | Driveshaft |

| 10 - | Plate spring |

| q | Assembly position → Fig. |

| 11 - | Retaining ring |

| q | Assembly position → Fig. |

| 12 - | Circlip |

| q | Replace |

| q | Insert and remove with long nose pliers |

| 13 - | Left-hand side inner constant velocity joint |

| q | Only replace entirely |

| q | Releasing → Fig. |

| q | Grease → |

| q | Checking → Chapter |

| 14 - | Right-hand side inner constant velocity joint |

| q | Only replace entirely |

| q | Releasing → Fig. |

| q | Grease → |

| q | Checking → Chapter |

| 15 - | Driveshaft with inner joint (tripod) |

| q | Only vehicles with 4-cylinder engine and automatic gearbox |

| q | The inner joint cannot be repaired |

| q | Replace if damaged |

| 16 - | Allen bolt |

| q | First tighten diagonally to 10 Nm |

| q | Tighten completely to 70 Nm |

| q | Replace after each removal |

| 17 - | Tightening clip |

| q | Tighten → Fig. |

| 18 - | Dust guard of the inner constant velocity joint (tripod) |

| q | Only vehicles with 4-cylinder engine and automatic gearbox |

| q | Remove the outer constant velocity joint if the dust guard is to be replaced |

| q | Clean the driveshaft properly before fitting the new dust guard |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|